In the realm of engineering and product design, custom polyurethane parts have emerged as a cornerstone of innovation, delivering unparalleled durability, flexibility, and adaptability. These advanced components not only meet but exceed industry standards, empowering engineers to navigate intricate challenges with precision-tailored solutions. By pushing the boundaries of conventional design, custom polyurethane parts are reshaping diverse industries, redefining performance benchmarks, and paving the way for groundbreaking advancements. Join us as we delve into how these transformative elements are revolutionizing engineering and product design across various sectors.

At Uniflex, Inc., we understand that the demands of modern engineering and product design require materials that can keep pace with innovation. That’s why we offer custom-molded polyurethane solutions engineered to your precise specifications—delivering exceptional performance, longevity, and design flexibility. Whether you’re developing prototypes, seeking short-run production, or scaling up for full manufacturing, our in-house capabilities, from advanced mold-making to precision casting, ensure consistent quality and reliability across every component.

Let us help you overcome complex engineering challenges with materials built to perform under pressure. Partner with Uniflex, Inc. today and discover how our high-performance polyurethane parts can elevate your project from concept to completion.

👉Also Read: Are Polyurethane Wheels Worth It? Performance, Durability, and Use Cases Analyzed

The Role of Custom Polyurethane Parts in Modern Engineering

When it comes to withstanding high pressure and abrasion, custom polyurethane components are in a league of their own. Unlike traditional materials, polyurethane parts offer superior durability and performance, making them indispensable in challenging environments. This resilience is coupled with exceptional thermal insulation properties, allowing these components to thrive in extreme temperatures, whether hot or cold, while minimizing friction.

The impact of custom polyurethane parts on engineering and product design cannot be overstated. These tailored solutions are transforming how engineers approach complex projects, enabling them to meet specific design and performance criteria that were once considered unattainable. Leveraging the unique properties of polyurethane, engineers enhance overall design processes, pushing the boundaries of modern engineering.

Custom polyurethane parts are redefining engineering standards, meeting precise specifications, and excelling in demanding applications, setting new benchmarks for performance and innovation. As more industries recognize the potential of these components, the role of cast urethane in engineering continues to expand, heralding a new era of design and efficiency with cast polyurethane products.

Key Benefits of Custom Polyurethane Parts

Custom polyurethane parts offer a range of performance advantages that make them a preferred choice across industries:

- Exceptional Durability: Polyurethane provides superior abrasion and impact resistance, significantly extending part lifespan compared to traditional plastics and rubbers. This reduces the frequency of replacements and minimizes operational downtime.

- Cost Efficiency: Thanks to their long-lasting performance, polyurethane components lead to substantial cost savings over time, both in maintenance and replacement expenses.

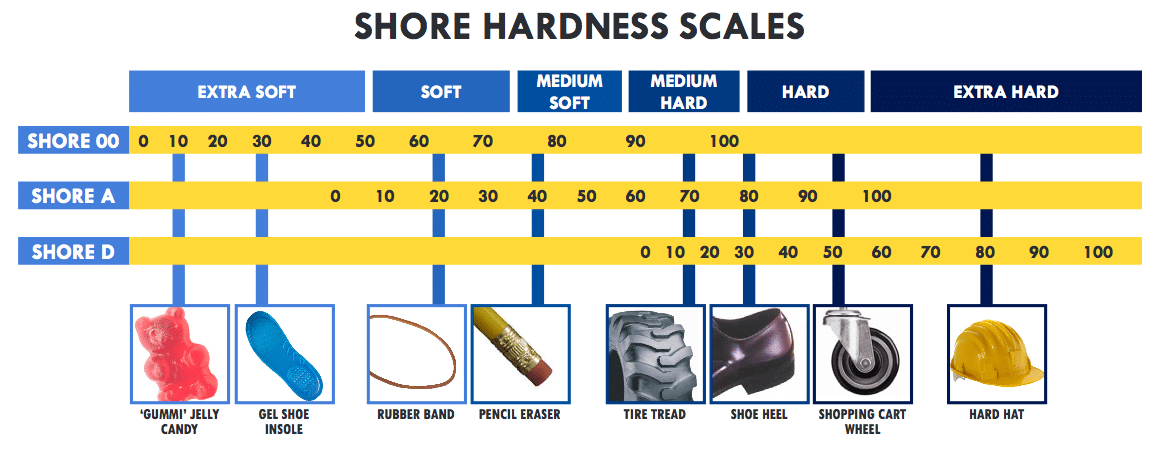

- Versatility and Customization: Polyurethane elastomers can be formulated with varying levels of hardness, flexibility, and resilience. This allows engineers to design lightweight yet durable parts tailored to specific mechanical requirements.

- Resistance to Harsh Environments: Polyurethane performs reliably in aggressive conditions due to its excellent resistance to petrochemicals, moisture, corrosion, and wear.

- Noise and Vibration Control: Its inherent vibration-dampening properties make polyurethane ideal for applications where noise reduction and impact absorption are critical.

These combined qualities—durability, adaptability, and chemical resistance—make custom polyurethane parts essential for modern engineering solutions across a wide range of demanding applications.

👉Also Read: What is Polyurethane and How Does it Compare to Traditional Plastics?

Design Freedom with Custom Polyurethane Components

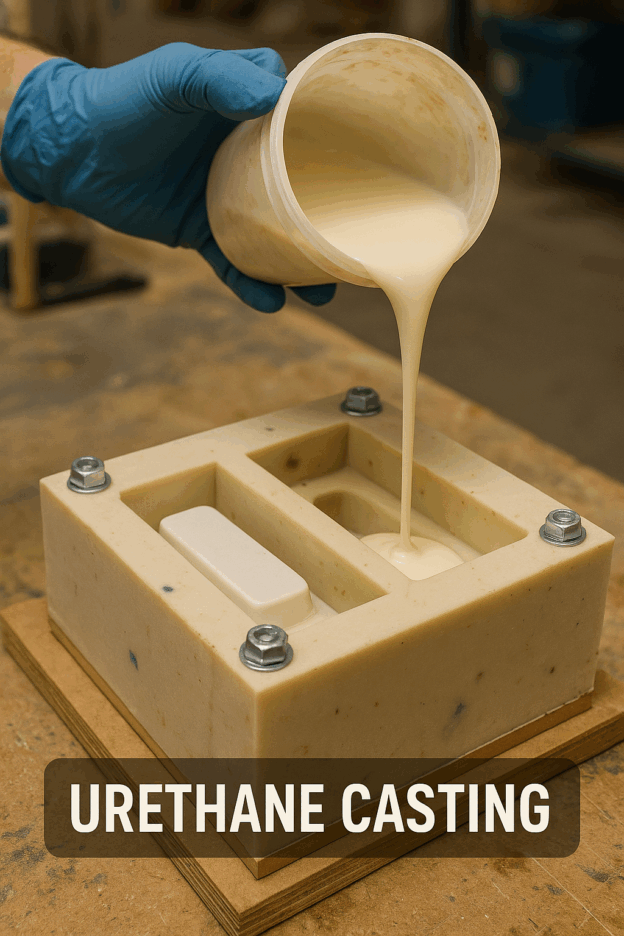

Custom polyurethane components offer exceptional design flexibility, empowering engineers to move beyond the limitations of standard parts. With the ability to mold polyurethane into virtually any shape or size, even highly complex geometries become achievable, enabling precision-fit solutions tailored to exact specifications.

This material versatility allows for the fine-tuning of mechanical properties such as hardness, elasticity, and load-bearing capacity. Whether a project requires enhanced durability, vibration dampening, or chemical resistance, polyurethane can be formulated to meet the specific demands of the application.

By eliminating the constraints of off-the-shelf components, custom polyurethane parts open the door to innovative engineering solutions, enhancing performance, improving functionality, and advancing product design across a wide range of industries.

Material Performance Optimization

One of the key advantages of custom polyurethane manufacturing is the ability to optimize material performance for specific applications. This process allows for:

- Precise tailoring of dimensions and part features

- Customization of properties such as hardness, flexibility, and load capacity

- Enhanced durability and functionality under demanding conditions

- Strict adherence to exact design specifications ensures peak performance and longevity

Polyurethane’s exceptional resilience makes it ideal for high-stress environments, including automotive systems, industrial machinery, and heavy-duty equipment. Unlike traditional materials such as rubber, polyurethane maintains its structural integrity and performance consistency under pressure, wear, and exposure to harsh elements.

Working with an experienced polyurethane manufacturer is essential to unlock the full potential of the material. Skilled manufacturers can fine-tune formulations to meet unique performance goals, ensuring components not only meet but often exceed operational expectations.

Furthermore, specialized polyurethane types—such as polyether urethane—offer additional performance benefits like superior elasticity, hydrolytic stability, and resistance to water and moisture. These attributes make them particularly valuable in applications exposed to fluctuating environmental conditions.

By optimizing material properties at the design and manufacturing stages, custom polyurethane components deliver exceptional reliability, versatility, and extended service life, raising the bar for performance across industries.

Cost Efficiency in Production

The durability of custom polyurethane parts translates to significant cost savings for manufacturers. Minimizing the need for frequent replacements and repairs, polyurethane components reduce operational downtime and maintenance costs. This reliability ensures manufacturing processes run smoothly, achieving cost efficiency in production.

Polyurethane parts offer several advantages over metal components:

- They are typically more affordable, providing savings on machining and welding expenses.

- Integration of polyurethane components streamlines production workflows by minimizing the need for secondary operations.

- Custom-molded urethane parts often reduce or eliminate the need for secondary finishing processes, leading to additional savings. Additionally, cast urethane parts can enhance durability and performance in various applications.

The cost efficiency of custom molded polyurethane parts is evident in their ability to enhance manufacturing efficiency. Improving product quality and reducing downtime, these components contribute to a more efficient and cost-effective production process. The combination of durability, affordability, and ease of integration makes polyurethane a smart choice for manufacturers looking to optimize their production costs.

Versatility Across Industries

Polyurethane’s unique combination of durability, flexibility, and customizability has made it an indispensable material across a broad range of industries.

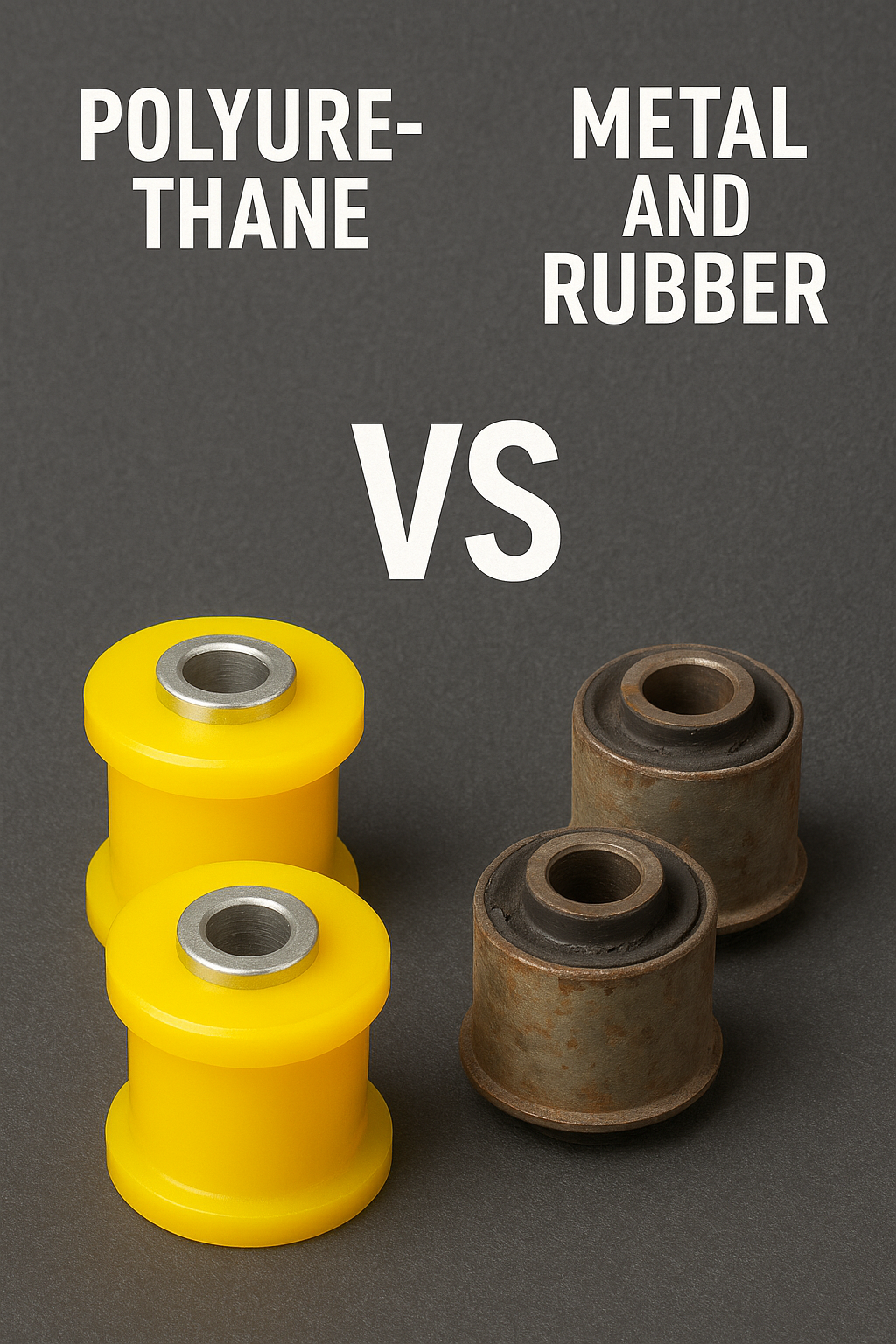

In the automotive sector, polyurethane components are used in applications ranging from seat cushions to suspension bushings. These parts offer superior wear resistance, load-bearing capacity, and vibration dampening, outperforming many traditional materials.

The aerospace industry benefits from polyurethane’s lightweight and high-strength characteristics, which contribute to improved fuel efficiency and reduced operational costs.

In construction, polyurethane is widely used for insulation, sealants, and protective coatings, thanks to its excellent thermal resistance, structural stability, and adaptability in diverse environmental conditions.

The biomedical field is increasingly exploring polyurethane for applications such as medical implants, catheters, and tissue engineering scaffolds, due to its biocompatibility, flexibility, and resilience under physiological conditions.

In consumer goods manufacturing, polyurethane is prized for its durability, abrasion resistance, and comfort, making it a preferred material for products like footwear, furniture, electronics, and sporting equipment.

The global polyurethane market is expected to experience substantial growth, fueled by rapid industrialization and expanding infrastructure projects. In parallel, there is a growing emphasis on eco-friendly polyurethane solutions, prompting innovation in sustainable formulations and greener manufacturing practices.

This broad applicability and ongoing development reinforce polyurethane’s status as a versatile, future-ready material, capable of meeting the evolving demands of modern industries.

Case Studies: Success Stories with Custom Polyurethane Parts

Custom-molded polyurethane components have demonstrated significant value across multiple industries, offering measurable performance improvements and cost savings.

In the automotive sector, custom polyurethane parts have enhanced the durability of seats and seat belt systems. Their ability to withstand constant use and stress has reduced the frequency of replacements, ultimately lowering maintenance costs and improving product lifespan. This is a clear example of how polyurethane’s resilience contributes directly to operational efficiency.

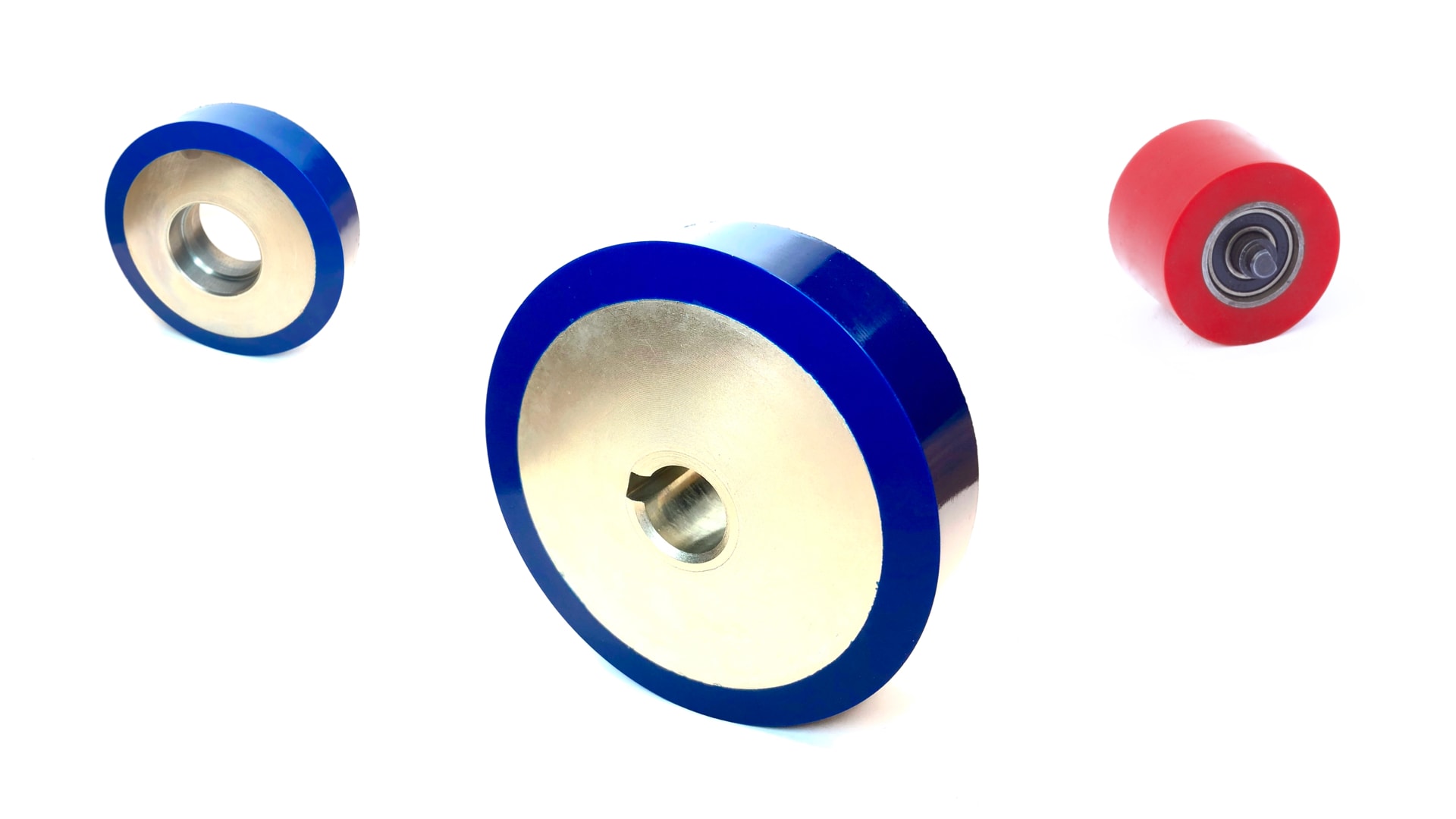

In industrial equipment and packaging, custom-molded polyurethane rollers have improved production throughput and minimized equipment downtime. Their superior wear resistance and precisely calibrated durometers allow them to perform consistently under high loads and repeated use. These features reduce maintenance demands, increase service intervals, and contribute to substantial cost reductions.

In the consumer goods sector, manufacturers benefit from custom polyurethane components that offer high precision, speed up production cycles, and reduce material waste. The use of custom molds ensures that parts meet exact specifications, improving both the functionality and aesthetic quality of finished products. Custom urethane molding also supports consistent output in high-volume applications, allowing manufacturers to maintain quality while optimizing performance.

These success stories underscore the transformative impact of custom polyurethane parts. By incorporating them into their operations, companies are able to streamline workflows, reduce downtime, and achieve greater consistency in both performance and product quality. The adaptability, durability, and precision offered by polyurethane make it an essential solution for engineering and manufacturing innovation.

👉Also Read: Urethane Casting Costs Explained: What You Need to Know Before You Start

Future Trends in Custom Polyurethane Manufacturing

Emerging technologies in custom polyurethane manufacturing are poised to transform the landscape of engineering and product development. One notable advancement is Reinforced Reaction Injection Molding (RRIM)—a process that combines rigid and flexible polyurethane characteristics with fiber reinforcements. This technology expands design flexibility, enabling the production of lightweight yet high-strength components ideal for demanding applications. RRIM is already driving innovation in sectors such as automotive, aerospace, and consumer goods, thanks to its ability to deliver enhanced structural integrity and performance through efficient chemical reactions during molding.

As polyurethane processing methods continue to evolve, we can expect notable improvements in both material performance and manufacturing efficiency. Enhanced formulation techniques, automation, and precision tooling are enabling faster prototyping, reduced waste, and improved scalability—all critical for modern engineering demands.

Partnering with an Experienced Polyurethane Manufacturer

Choosing the right polyurethane manufacturer is essential for achieving successful outcomes in both prototyping and full-scale production. A seasoned manufacturing partner brings critical value to the development process, offering technical expertise and hands-on support during prototyping, testing, and final production, helping to mitigate risks and ensure design integrity from the outset.

Experienced polyurethane manufacturers possess advanced capabilities, including precision CNC machining, injection molding, and custom tooling. These competencies enable the production of highly complex components with tight tolerances and consistent quality.

Equally important is a strong commitment to quality control. A reputable manufacturer ensures that every part is fabricated using the appropriate polyurethane formulation and adheres to rigorous quality standards. This focus on quality safeguards performance reliability, and enhances the long-term durability of the final product.

By collaborating with a knowledgeable polyurethane partner, engineers can access tailored solutions that align precisely with project specifications. The ability to customize formulations, design features, and production methods provides a distinct competitive advantage, streamlining development timelines and improving overall product performance.

Uniflex, Inc.: Your Strategic Partner in Custom Polyurethane Solutions

At Uniflex, Inc., innovation meets precision. As a premier manufacturer of custom molded urethane products, we specialize in delivering engineered solutions that meet the highest standards of performance and reliability. With decades of experience, a customer-centric approach, and robust in-house capabilities—including precision molding and rapid prototyping—we provide tailored polyurethane components designed to meet your exact specifications.

From initial concept to final production, our team collaborates closely with engineers and product developers to ensure each project is executed with accuracy, consistency, and efficiency. Whether you’re seeking to optimize material performance, enhance product longevity, or explore design innovations, Uniflex, Inc. is equipped to help you move from prototype to production with confidence.

Ready to turn your vision into a reality?

Partner with Uniflex, Inc. to access the technical expertise, flexibility, and personalized support you need to elevate your product design. Contact us today at 248-486-6000 to discuss your project requirements and discover the advantages of working with a trusted leader in custom polyurethane manufacturing.