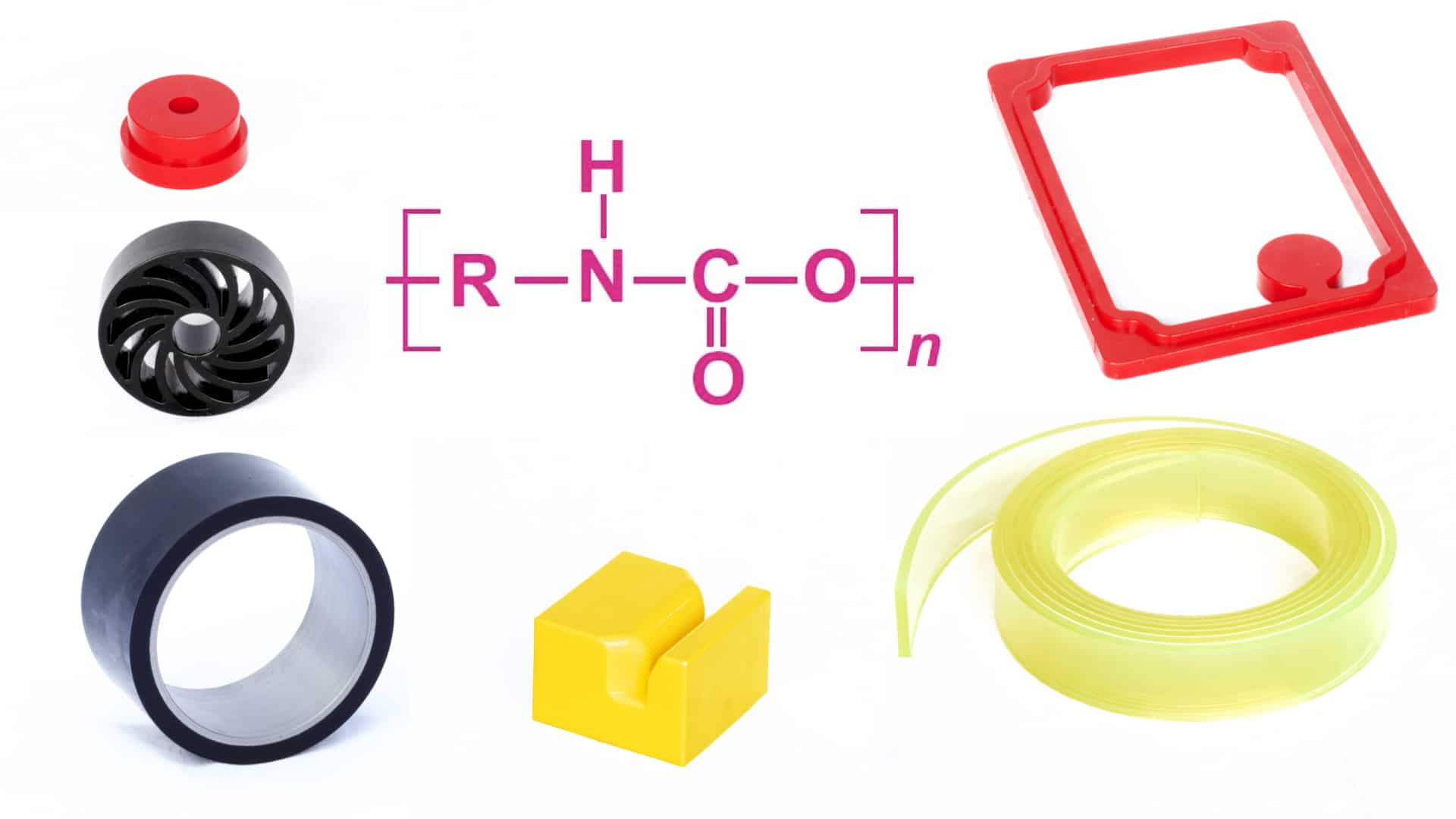

Urethane Compound Selection Guide

Selecting the correct polyurethane formulation for the job is the most important step in the polyurethane manufacturing process. Although polyurethanes fall within in the same family, not every urethane compound is the same. There are many different types of polyurethane that are chemically different and therefore have varying physical properties. Some perform better in certain environments while others do not. Sometimes the only difference between a good urethane part and a bad urethane part is simply the formula. Please reference the information below to help guide you in selecting the correct urethane compound. If you have any questions, be sure to contact us and we will help guide you through selecting the correct compound for your application.

Polyurethane Compounds We Offer:

Standard Polyether Urethane

Our standard polyether material is a diamine-cured, PPG-TDI polyether urethane that is very commonly used throughout the industry. This urethane formulation is very favorably priced and provides a nice balance between performance and cost. It provides excellent impingement resistance, excellent hydrolytic stability, and good rebound. Available in both Shore A and Shore D hardness.

Common applications:

- Standard urethane rollers

- Bumpers

- Dunnage

- Body blocks

- Sheet

- Washers

- Bar

- Rod

- Bushings

- Most urethane parts

Physical Data:

Shore A Compounds:

Shore D Compounds:

Performance Polyether Urethane

Our performance polyether is a diamine cured PTMEG-TDI polyether urethane that is another staple of the cast urethane industry. This formulation offers a much higher performance material that is excellent for dynamic applications such as high-speed urethane rollers and urethane casters. Since this formula is a polyether material, it provides excellent impingement resistance, hydrolytic stability, and rebound. This urethane formula does have a higher cost than a standard polyether, so it is highly recommended for applications that absolutely require it. Available in both Shore A and Shore D.

Common applications:

- High Speed Rollers

- High Load Rollers

- Urethane casters

- Urethane wheels

- Rod stock

- Sheet

- Tube

- Bar stock

Physical Data:

Shore A Compounds:

Uniflex Comp_Ether_Performance

Shore D Compounds:

Premium_d_scale

Polyester Urethanes

Our polyester formula is diamine cured, TDI-polyester urethane system that is commonly used throughout the industry. This formulation provides a very tough compound that works perfectly for applications that require excellent sliding abrasion resistance, high tear strength, resistance to chemicals such as oils and solvents, as well as vibration dampening. Polyesters generally do not have the rebound capabilities of polyesters and are typically a more “dead” material. They do, however, provide a much tougher urethane part in terms of tear resistance and tensile strength. It is not recommended to use polyester urethanes in wet or humid environments as they have a tendency to undergo hydrolysis.

Common applications:

- Scraper blades

- Chute liners

- Pads

- Some rollers

- Rod stock

- Sheet

- Tube

- Bar stock

Physical data:

Uniflex Compounds_Esters

MDI Urethanes (FDA compliant polyurethane*)

We offer many MDI urethane formulations in both polyether and polyester urethanes, which can be selected based on the user’s application. Although commonly used in the food and beverage industry, MDI materials can also be used for other applications where low compression set and high rebound are needed (polyether-MDI) or where high tear resistance and tensile strength are need (polyester-MDI). Often, MDI’s tend to have much better dynamic properties, especially in the lower Shore A scale range and are excellent for urethane rollers and urethane casters.

We have diol cured MDI formulas that are compliant with FDA dry and wet food contact regulations (FDA 21CFR177.1680 and FDA 21CFR177.2600). *Some MDI formulas are not FDA compliant. Please be sure to specify the need for FDA compliant urethane if required.

Common applications:

- All food grade applications

- Rollers

- Washers

- Nozzles

- Bumpers

- Seals

- Gaskets

- Rod stock

- Sheet

- Tube

- Bar Stock

Physical Properties:

MDI-Polyether Compounds:

Uniflex Compounds_MDI Ether

MDI-Polyester Compounds:

UX_compounds_MDI ester

Not sure you see what you’re looking for in our standard formulas?

No problem! We have excellent chemists that we have been working with for decades that can development a formula specific to your application. We have a vast selection of various prepolymers and curatives that can be blended in ways that achieve almost any desired physical properties. Since we are a completely custom urethane shop, we are able to seamlessly integrate these new polyurethane formulas into our manufacturing facility. All you have to do is answer a few questions from us and we will take care of the rest.

Have Any Questions About Polyurethane Compounds?

Feel free to give us a call or contact us directly through our website. We have an experienced staff that is more than willing to help you out with whatever project you are working on!