What makes cast urethane products a go-to for diverse industrial applications? Their exceptional versatility and performance. Utilized in scenarios demanding resistance to abrasion, extreme temperatures, and heavy loads, these materials prove essential in enhancing operational longevity and efficiency. Through this exploration, we’ll uncover the science behind cast urethane’s resilience, delve into its array of industrial uses, and examine why companies are turning to cast urethane to meet the evolving demands of the industry.

Key Takeaways

- Cast urethane products from Uniflex, Inc. provide exceptional durability, impact, abrasion, and tear resistance for a variety of industrial applications, ensuring increased equipment runtime and efficiency.

- Uniflex, Inc. offers customizability in its urethane products, meeting specific industry needs with a range of hardness, colors, and compliance to standards, including FDA-approved hygienic solutions for food processing.

- Our custom casting process for low-volume production offers cost-effective, high-quality solutions with reduced tooling and shorter lead times, ideal for specialized applications and prototyping.

👉Also Read: Top-Quality Cast Urethane Products: Your Ultimate Guide to Durable Materials

Harnessing the Power of Cast Urethane for Industrial Success

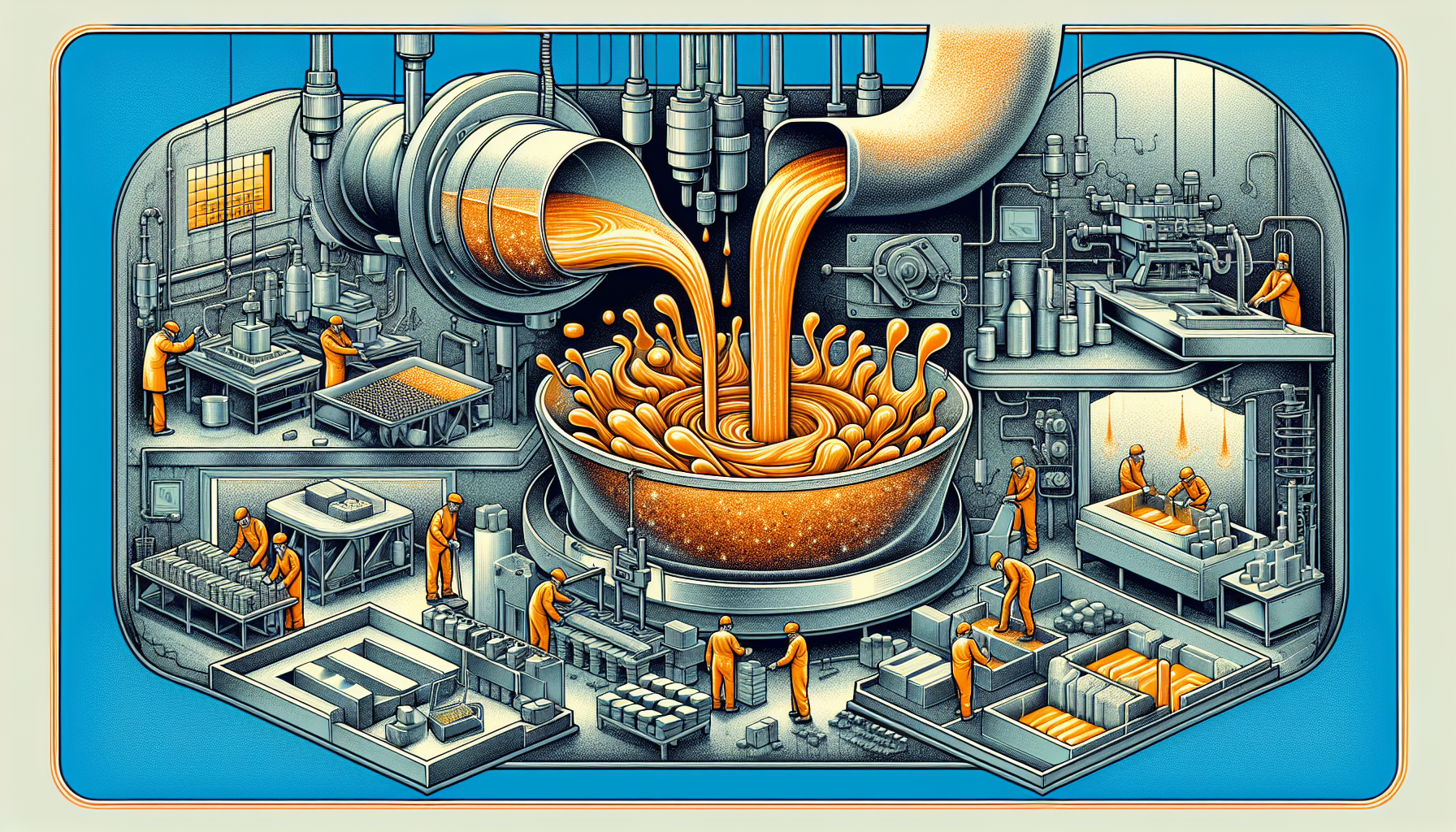

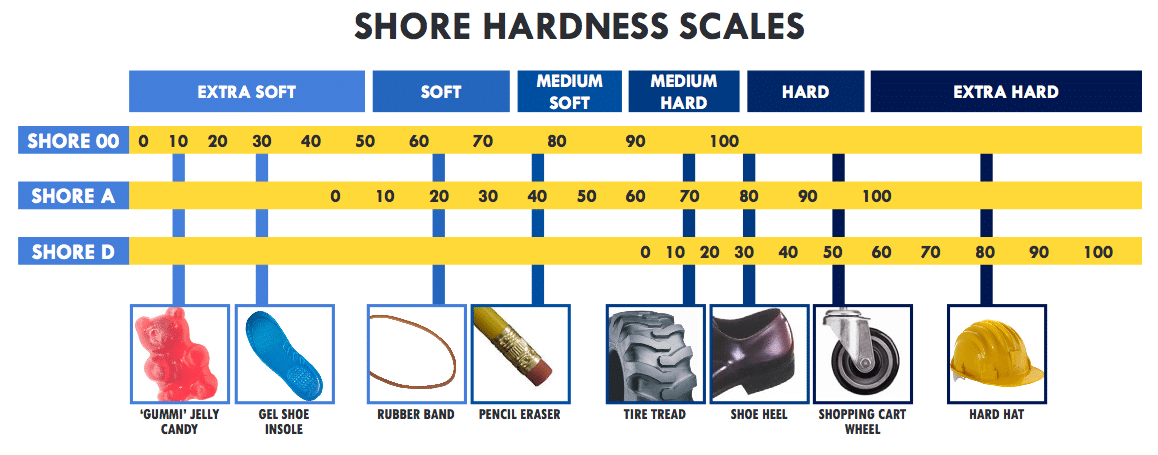

The industrial landscape is evolving, and with it, the need for materials that offer unparalleled strength, toughness, and durability. Cast urethane stands at the forefront of this revolution, providing a suite of properties that outshine traditional materials. At Uniflex, Inc., we lead in cast urethane technology, delivering a wide array of products ranging from Shore 10A to Shore 80D hardness, catering to the diverse demands of various industries. Our success stems from a fusion of cutting-edge manufacturing processes and a deep understanding of industrial applications.

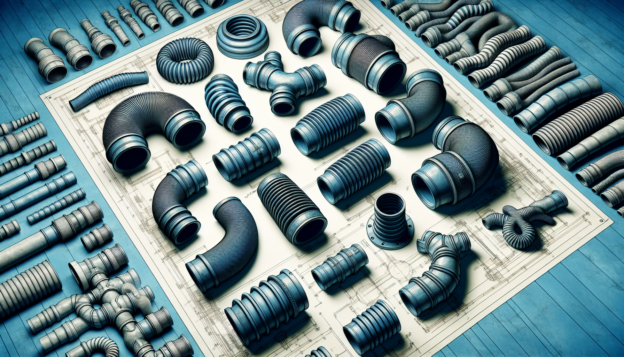

Some of the common cast urethane products that we provide include: Rollers, V-rollers, Skate Wheel Covers, Sleeve Coverings, Wheels, Bumpers, Bushings, Urethane-to-metal bonding, Liners, Coil Pads, Coil Spring Spacers, Sheet Metal Cushions, Seals, Rings, Scraper blades, Snow-plow wear bars, Buckets, Pallets, Transport fixtures, Body Blocks, Nozzles, Gears, Gaskets, Plugs, Caps, Polyurethane Cam Follower Sleeves, Couplings, and Pulleys.

The Uniflex, Inc. Advantage in Polyurethane Manufacturing

Accuracy is of utmost importance in polyurethane manufacturing, a principle that is evident in our custom polyurethane molding process at Uniflex, Inc. By meeting precise customer specifications and maintaining optimal functionality, we ensure that each product integrates flawlessly into the system it’s designed for. Our use of cost-effective silicone molds allows for design flexibility and minimal expenditure when modifications are needed.

Complex part geometries that often challenge other molding processes are a breeze for us, thanks to our expertise in urethane casting. This capability allows for intricate designs such as undercuts and variable section thicknesses, expanding the horizons of what can be manufactured. Moreover, we offer a wide spectrum of material options, including custom colors and standards compliance, to meet and exceed versatility across applications.

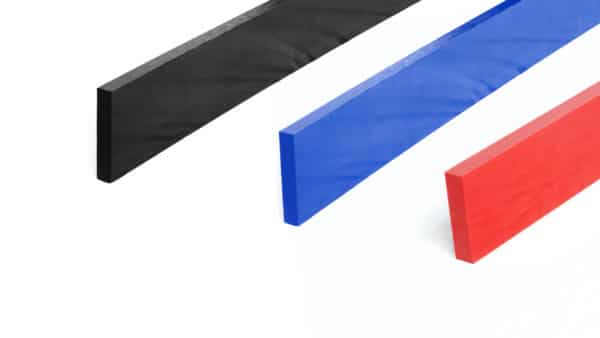

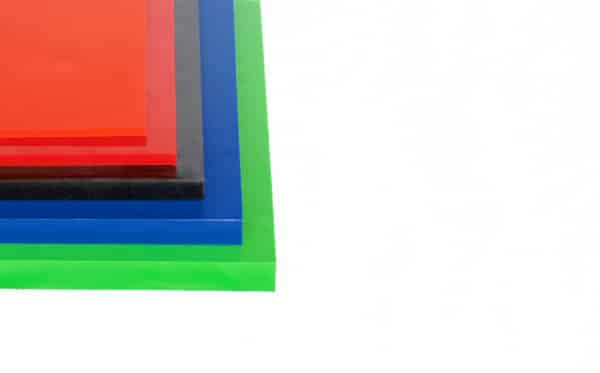

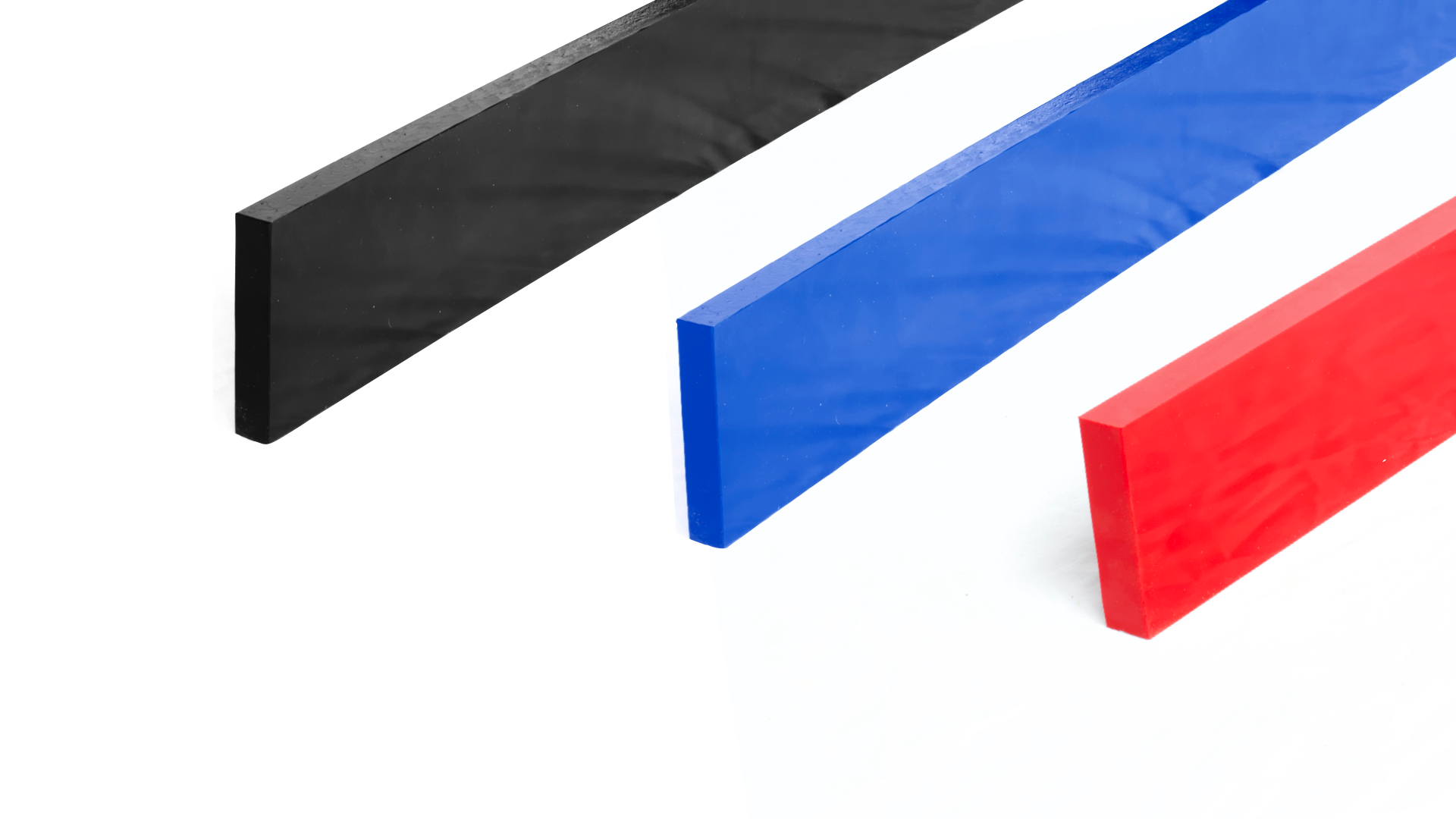

Customized Solutions with Urethane Sheets

In terms of sustainability and durability, our urethane sheets at Uniflex, Inc. are unparalleled. Here are some of their key features:

- Superior abrasion resistance capabilities, outperforming metals and plastics

- Ability to withstand demanding conditions and stand the test of time

- Resistance to ozone and thermal aging, making them ideal for long-term uses across a variety of applications

We offer a wide array of customization options for urethane sheet, catering to diverse needs with options such as:

- Adhesive-backed or raw material configurations

- Applications such as sleeve bearings, wear plates, and custom equipment components

- Tailored solutions that meet the specific demands of our customers

- Resistance to mold, mildew, and fungi

These features ensure the usability of our urethane sheets in industries with stringent hygienic requirements.

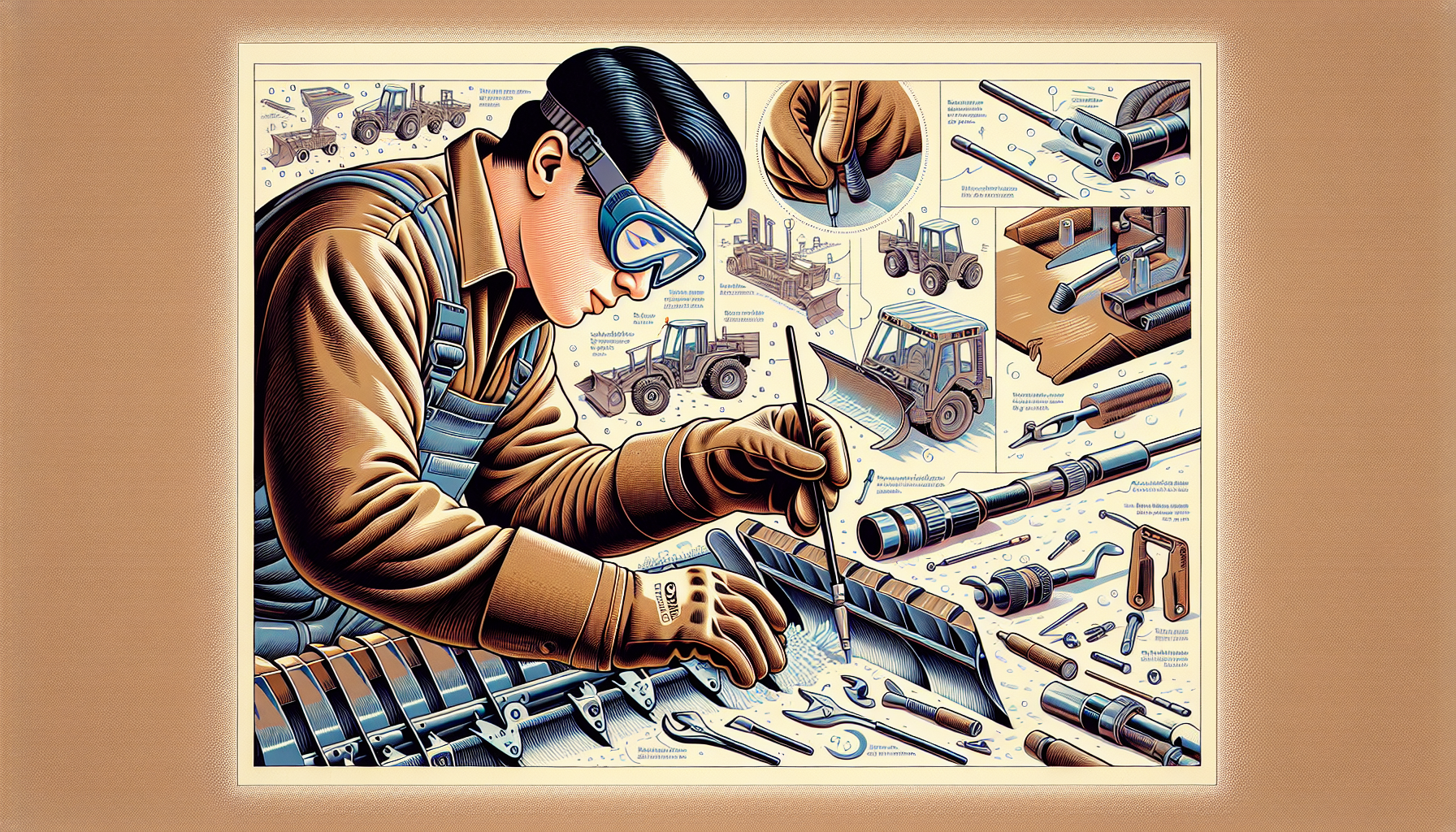

Addressing Wear Issues with Molded Urethane Products

For industries grappling with wear-related issues, our molded urethane products offer a sturdy resolution. With superior impact, abrasion, and tear resistance, our products contribute to increased runtime and reduced equipment downtime, especially in sectors like mining and heavy machinery. Our polyurethane bushings exemplify this durability, minimizing friction and sustaining continuous operations to enhance the longevity and efficiency of industrial systems.

Urethane’s capability to withstand heavy loads and abrasive conditions establishes it as a vital material in manufacturing environments. By addressing wear issues related to friction and burden, our molded urethane products ensure smooth, uninterrupted industrial processes, safeguarding the investments and operational efficiency of businesses.

The Spectrum of Uniflex Inc.’s Cast Urethane Elastomer Products

Serving as the backbone for numerous industries, cast urethane elastomer products boost machinery efficiency and deliver accurate sealing solutions in diverse sectors, including:

- Medical

- Automotive

- Bulk transport

- Material handling

- Mining

The unique combination of high-performance resins and the versatility of cast polyurethane elastomer products allows for a broad range of applications, including cast polyurethane products with specific performance characteristics.

Precision and Performance in Polyurethane Bushings

Our polyurethane bushings demonstrate the precision and performance inherent in our products. Exhibiting improved mechanical properties and reduced friction, they offer a higher load-bearing capacity than traditional rubber, making them ideal for a variety of industries, including automotive, healthcare, transportation, and manufacturing. These industries benefit from smoother operation and longevity, thanks to our bushings’ ability to reduce friction between moving and stationary components.

Not only are our bushings customizable for different levels of firmness, but they can also be produced in various colors and shapes to meet specific requirements. Their resistance to harsh conditions and their contribution to improved vehicle handling make them particularly valuable within transportation applications, including automobiles, commercial vehicles, and aircraft.

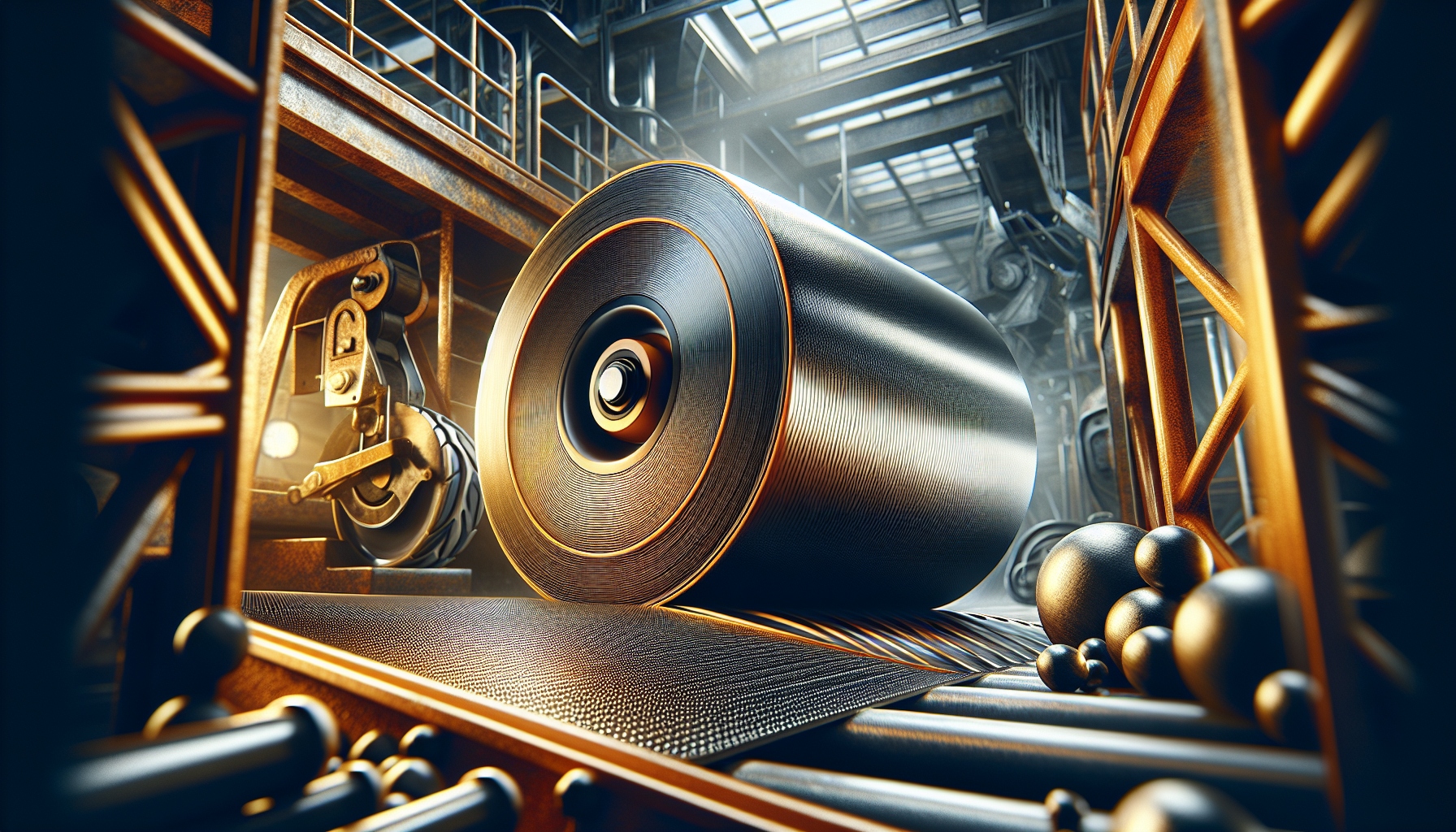

The Role of High-Performance Resins in Urethane Wheels

The superior durability and efficiency of urethane wheels are enhanced by the infusion of high-performance resins. The addition of nano-sized inorganic fillers results in wheels with improved tensile strength, thermal and chemical resistance, and enhanced surface properties. This meticulous engineering contributes significantly to the longevity of these wheels, making them ideal for the challenging conditions of material handling and bulk transport applications.

The result is a product that not only meets but exceeds the expectations for abrasion resistance and durability in demanding environments.

Innovative Applications of Cast Urethane in Various Industries

Our innovative approach to cast urethane has spurred significant improvements in operational efficiency across various industries. From the precision required in textile machinery to the robustness needed in food processing, cast urethane’s flexibility and adaptability are revolutionizing the way we operate. Urethane casting serves as an agile manufacturing method for low-volume production and is particularly vital for industries such as medical, electronics, and defense, where prototypes often require regulatory approval.

The innovative applications of our cast urethane are seemingly limitless, addressing the needs of virtually any application. Whether enhancing the durability of electronic components or providing critical solutions for defense equipment, our polyurethane coatings are recognized for their exceptional durability and chemical resistance. The adaptability of our cast urethane products ensures they remain integral to the advancements and efficiency of an ever-evolving industrial landscape.

Enhancing Food Processing with Hygienic Urethane Solutions

In the food processing industry, hygiene is paramount, and Uniflex, Inc.’s hygienic urethane solutions are designed to meet FDA standards, suitable for a variety of applications from dry goods like sugar and rice to wet products such as meat and fish. These urethane sheets play a crucial role in reducing wear from abrasive materials, ensuring consistent performance, easy maintenance, and durability that stands up to the rigorous demands of food processing.

Additionally, the hydrophobic properties of urethane can be adjusted to suit different processing environments, a critical factor in ensuring that the materials used in food processing are safe and effective. Uniflex, Inc.’s urethane solutions enhance operational efficiency and reduce maintenance costs, making them a vital component in the food processing industry’s pursuit of excellence and safety.

Meeting the Demands of Heavy Industry with Robust Urethane Components

In the rigorous environments of heavy industry, components are required to endure extreme conditions. Uniflex, Inc.’s robust urethane components excel in these scenarios, providing solutions that are not only resistant to chemical corrosion and extreme temperatures but also offer an extended service life, proving to be cost-effective in the long term. The maritime and marine sectors, for example, rely on urethane components for their ability to endure harsh saltwater conditions, making them indispensable for buoyancy devices and underwater equipment.

The chemical resistance of urethane materials is particularly significant in harsh industrial applications, such as the slush pumps used in petroleum engineering. Here, durability against chemical corrosion is paramount, and Uniflex, Inc.’s urethane components deliver on this need with unwavering reliability.

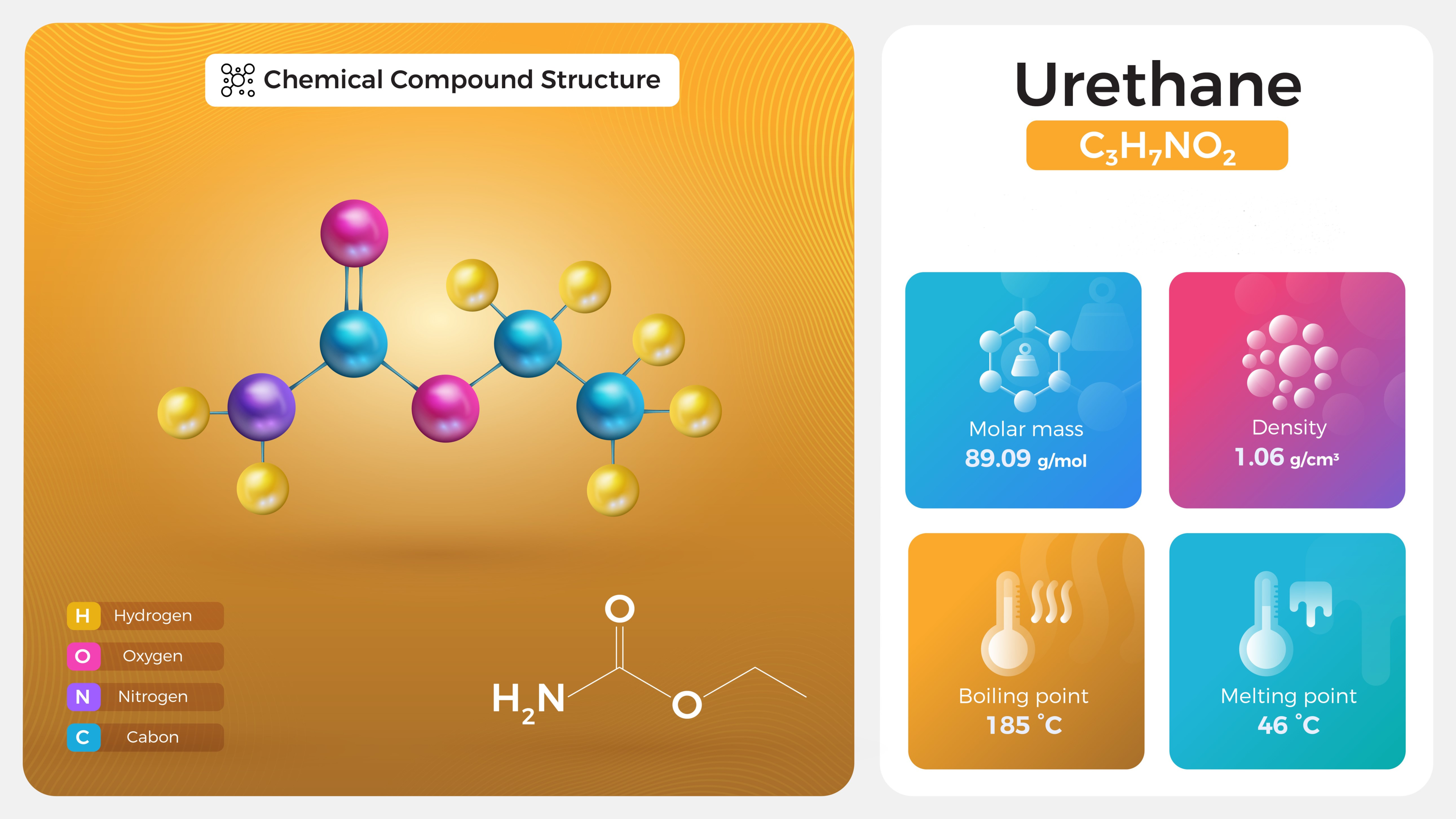

The Physical Properties and Benefits of Polyurethane Materials

Renowned for their resilience and flexibility, polyurethane materials offer the following benefits:

- Exceptional resistance to moisture and chemicals

- Impervious to extreme temperatures

- Wide range of chemical resistance

- Maintains integrity in challenging conditions

- Exceptional load-bearing capacity, resisting deformation under pressure

These qualities make polyurethane the correct material for heavy-duty applications, and it’s no wonder that polyurethane products, such as polyurethane rings and polyurethane sheets, are in high demand.

What truly sets polyurethane apart is its customizable hardness levels, ranging from rubber-soft to plastic-hard. This enables it to outperform other materials like plastics and rubber in terms of:

- Impact resistance

- Elasticity

- Abrasion and cut resistance

- Load-bearing capacities

Additional perks of polyurethane include:

- Custom production in various colors with ultraviolet shielding

- Excellent electrical insulating properties

- Enhanced toughness for superior shock absorption

Inviting Industries to Explore Customized Urethane Solutions with Uniflex, Inc.

At Uniflex, Inc., we encourage industries across the globe to explore the possibilities offered by our custom urethane solutions. These solutions not only improve product longevity but also contribute to substantial cost savings, paving the way for increased efficiency and innovation within companies. We are adept at adapting cast urethane products for a plethora of applications, from gaskets to wheels, ensuring that each industry finds the perfect fit for its unique challenges.

By embracing our tailored solutions, industries can transcend conventional performance limits and set new standards in their respective fields.

👉Also Read: All You Need to Know About Urethane

Discover Our Custom Urethane Solutions

Explore Uniflex, Inc.’s comprehensive range of high-quality urethane products and tailor your order to exact specifications. Whether you need durable bumpers, versatile snow plow blades, or precision-machined rods and strips, we provide customized solutions that enhance efficiency and performance. Contact us today to elevate your operations with Uniflex’s commitment to quality and innovation.