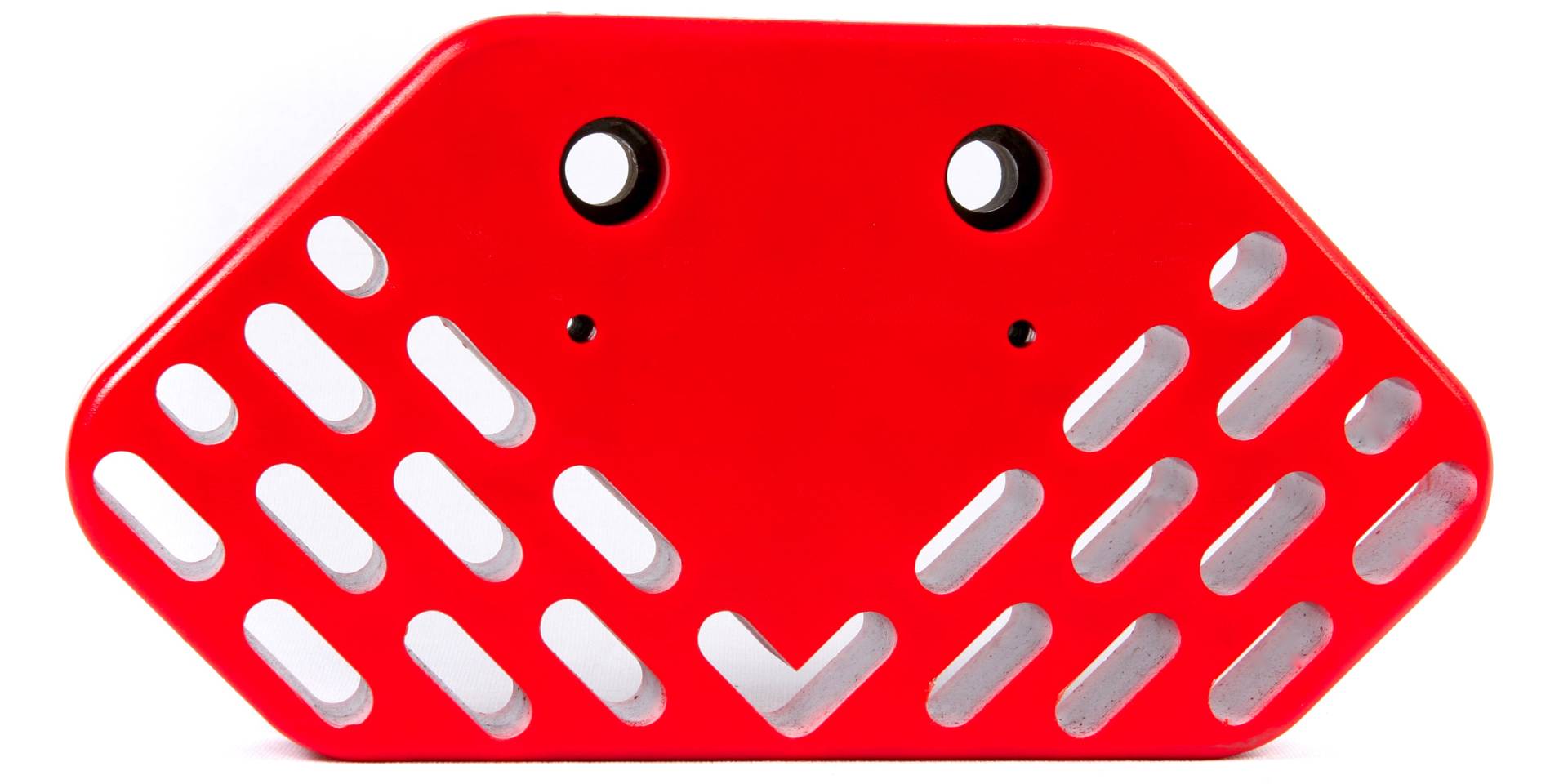

Polyurethane Bumpers

Uniflex’s Polyurethane Rubber Mold Bumpers go beyond just preventing product damage; they are the cornerstone of noise reduction, durability, and cost-effectiveness. These custom-molded polyurethane bumpers are the ideal solution for harsh environments where parts face repeated impacts and serve as safety measures where potential impacts are a concern.

Key Features:

Product Damage Prevention: Protect your valuable equipment and components with Uniflex’s polyurethane bumpers. These bumpers act as a barrier, effectively preventing damage and maintaining the integrity of your assets.

Noise Reduction: Enjoy a quieter and more comfortable working environment. Our polyurethane bumpers significantly reduce noise, making your workplace more conducive to productivity and safety.

Durability and Longevity: Our polyurethane bumpers are built to withstand the harshest conditions and constant impacts. Their extended lifespan ensures that you can rely on them for years to come, reducing maintenance costs.

Versatile Safety Measures: Industries across the globe, including automotive, robotics, mining, and oil, have embraced cast polyurethane bumpers as their top choice. Their versatility makes them an essential safety measure wherever the potential for impact exists.

Uniflex’s Polyurethane Bumpers offer a comprehensive solution for protecting your equipment and creating a quieter and safer work environment. Trust in the durability, longevity, and versatility of our bumpers.

Ready to elevate the safety and efficiency of your operation? Explore Uniflex’s Polyurethane Bumpers at Uniflex and discover the difference that quality and reliability can make.

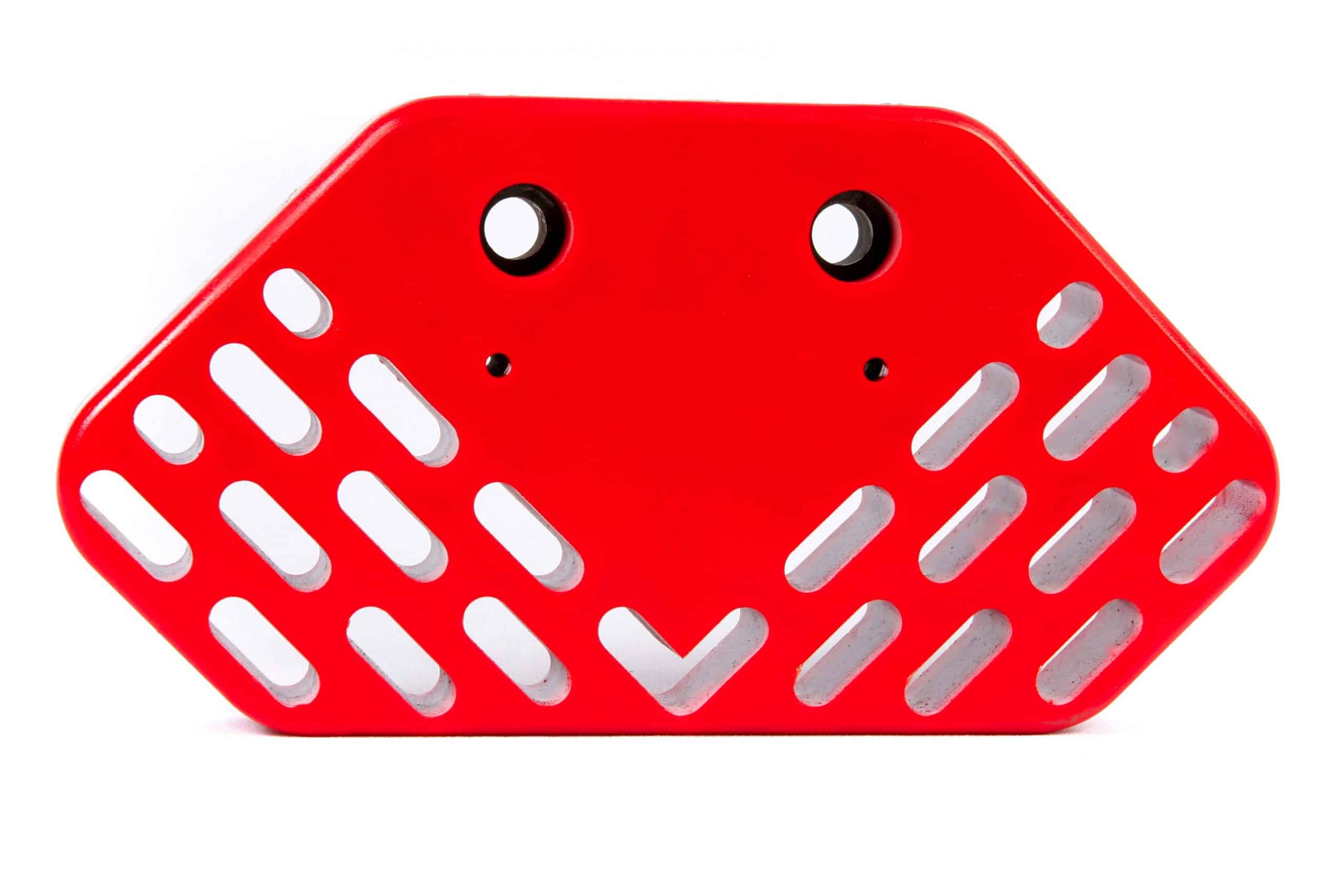

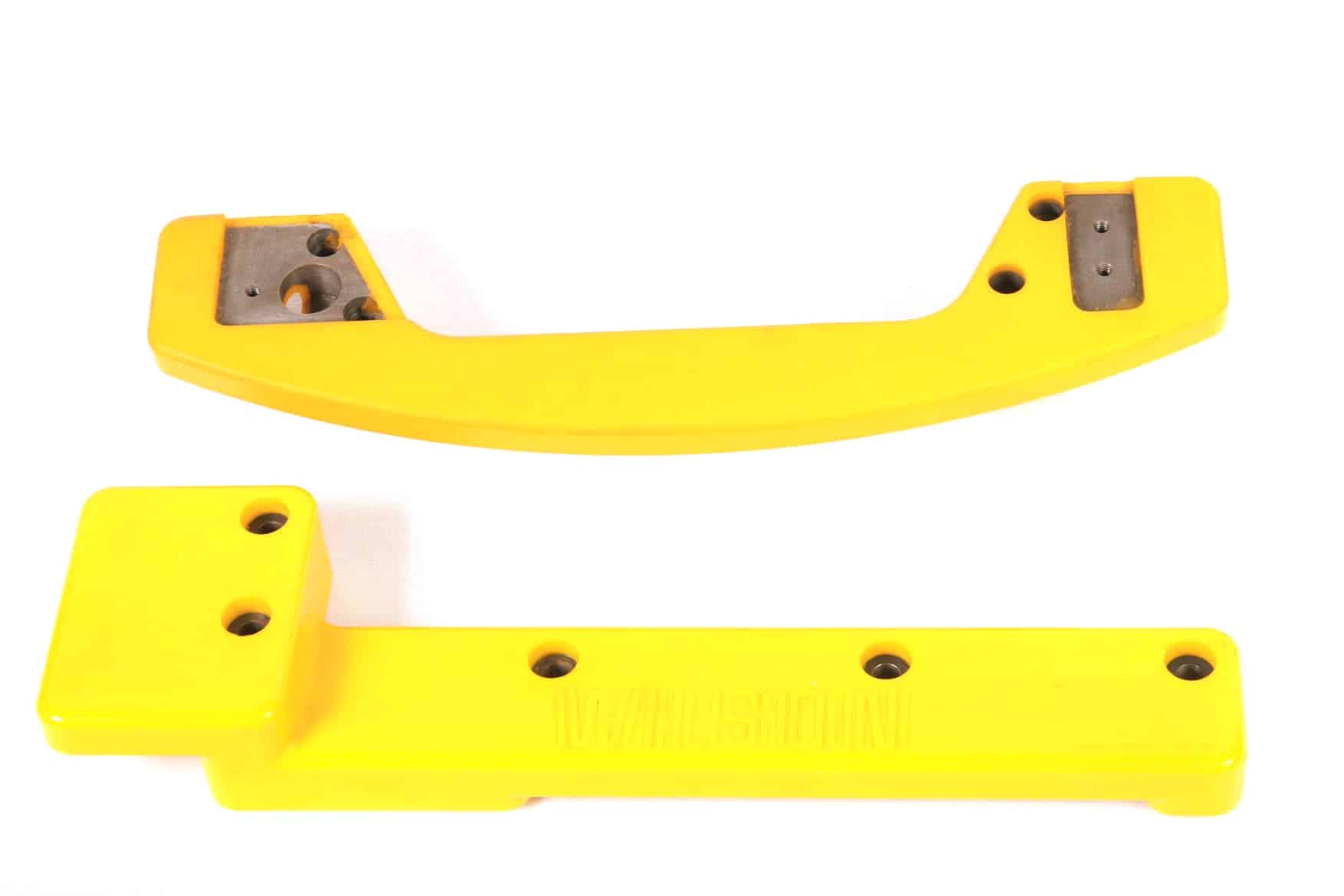

Polyurethane Bumpers

Uniflex’s urethane bumpers can be manufactured in accordance with your specific requirements, so send us your drawings or have our team of engineers work with you to design a solution unique to your application!

Here at Uniflex, we are able to design, machine, and manufacture under one roof, accelerating your project into production. Products can enter production in days! We follow extremely refined design, machining, and urethane casting procedures that will help save you time and money on your next project.

We cast urethane parts in both high and low volume production runs with very economical tooling!

Why polyurethane?

Polyurethane is:

- Resilient

- Durable

- Cost Effective

- Abrasion Resistant

- Impingement Resistant

Polyurethane is:

- Chemical and Oil resistant

- Non-absorptive

- Non-conductive

- Vibration and Shock Dampening

- Extremely Versatile

If you want to learn more about polyurethane bumpers or would like to request a quote for a custom job, make sure to contact us! We have a staff of experienced engineers ready to answer your questions and help guide you from concept to solution.

More Products

Incredibly useful due to its ability to be molded into a seemingly infinite number of shapes, sizes, and hardness ranges.

We offer high quality, custom rubber compression and transfer molding to produce high quality, economical rubber products that adhere to your specific requirements.

Incredibly useful due to its ability to be molded into a seemingly infinite number of shapes, sizes, and hardness ranges.

We are able to hold the most stringent tolerances that always meet or exceed customer expectations while ensuring an economical price.

We supply more styles and sizes of Kadant Unaflex brand Expansion Joints than any other distributor in the world and offer some of the most competitive pricing available.

Our product line includes molded & pultruded grating, handrail, ladders, structural shapes, stair treads, grating accessories, and FRP doors.

Custom manufactured from our famous non-conductive, ultra-durable UNIDURE© material, our electrical safety devices can be tailored for use in any lockout or tagging situation.

Our press fit cam follower sleeves are designed for ease of use and cost effective/efficient emplacement, while also maintaining exceptionally high quality.

The Uniflex Pipe Coupling has successfully solved frequent leakage, intensive maintenance, and stocking difficulties associated with ground join-pipe unions.