When industrial efficiency is at stake, polyurethane-coated rollers offer a viable solution. Known for their exceptional endurance and adaptability, these rollers are designed to meet the rigorous demands of various applications. This article will explain how polyurethane-coated rollers enhance system performance and the cost-effective, customized options available, with insights from leading manufacturers like Uniflex, Inc.

👉Also Read: Precision Engineered Conveyor Rollers: The Advantages of Urethane and Polyurethane

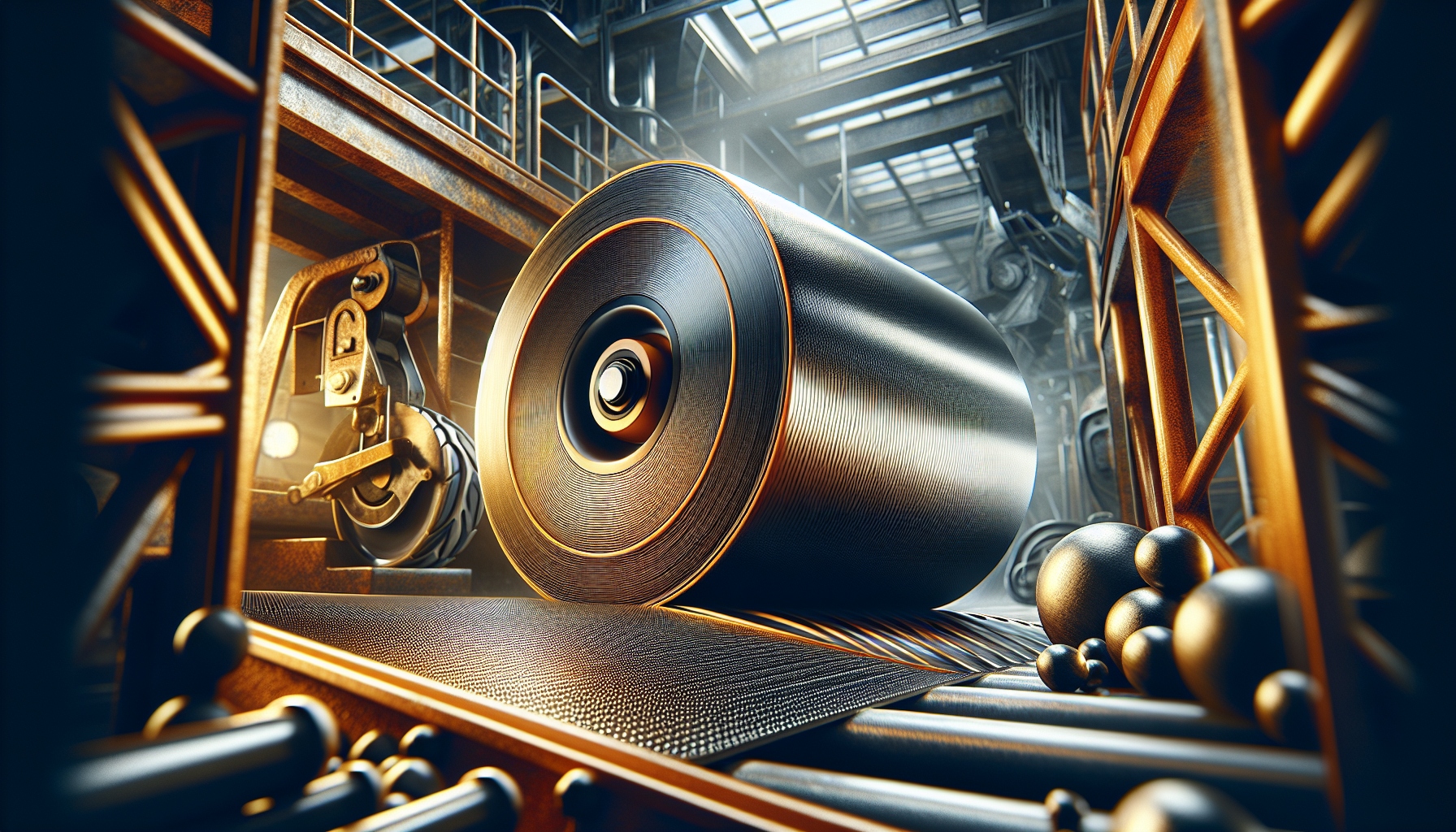

Introduction to Polyurethane Coated Rollers

Due to their versatility, polyurethane-coated rollers are a crucial element in multiple industries. They play an important role in the efficient functioning of conveyor systems and printing machines, making them stand out from other types of rollers. The reason behind this is their blend of durability, flexibility, and high performance when they are custom-made by top manufacturers.

At Uniflex Inc., we specialize in producing personalized molded urethane rollers and rubber products. This includes crafting customized polyurethane rolls and casted items, all developed through extensive research and development rooted in our domain experience. Our commitment to quality is demonstrated through the implementation of rigorous assurance measures over time, showcasing our dedication to reliability. Additionally, we consistently introduce innovations to further enhance the products and services we offer.

We offer a wide range of polyurethane roller types to cater to various industrial needs:

- Conveyor Rollers

- Skate Wheel Coverings

- Sleeve Coverings

- Idler Rollers

- Drive Rollers

- Cam Follower Rollers

- Mailroom Rollers

- Coated Bearings

- Coated Shafts

- V-rollers

- Pulleys

- Roller Coating, Recoating, and Repair

- Custom Options

With our diverse selection, we ensure that our polyurethane-coated rollers meet the demands of different applications and industries.

Advantages of Polyurethane Coated Rollers

Choosing polyurethane-coated rollers for your operations offers numerous benefits. These include outstanding abrasion resistance, ensuring high-quality finishes even in tough conditions. These rollers have an impressive lifespan of up to four times longer than traditional rubber rollers – resulting in reduced downtime and increased productivity.

The durability of polyurethane-coated rollers means they can withstand detrimental factors such as water, oil, extreme temperatures, and most chemicals without wearing out quickly. This not only helps maintain machinery but also prevents disruptions during processing due to their excellent vibration-dampening properties.

Polyurethane coated rollers are a smart investment that can significantly boost operational efficiency for businesses. They provide exceptional returns with improved product quality, maintaining equipment integrity, reducing maintenance costs, and increasing overall productivity across various applications.

Customization and Versatility

Polyurethane coated rollers stand out for their customization and adaptability, making them a popular choice across industries. These versatile rollers can be tailored to meet the specific needs of various material handling applications.

No matter if you need high-speed printing or heavy-duty conveyor equipment, polyurethane formulations can be customized to your exact specifications. You have the option of selecting from different durometers, diameters, lengths, and capacities to find the perfect fit for your machinery and optimize its performance.

The versatility of these coated rollers also extends beyond just customizing options, they are suitable for a wide range of materials such as delicate fabrics or heavy metal sheets without causing any damage. This makes them an ideal choice for businesses with diverse material handling requirements.

Specific Applications and Features of Polyurethane Rollers

Polyurethane coated rollers have been specifically developed with the unique needs and requirements of various industries in mind. They can be tailored for applications such as food processing, printing, or any other sector.

One distinguishing feature is its customizable durometer, which allows adjustments to cater to distinct applications. For example, a more rigid roller may be necessary for heavy-duty tasks while a softer one would better suit delicate materials.

For businesses adhering to strict sanitation standards like those in the food industry, FDA-approved options are available. These rollers meet all essential regulations ensuring that products remain safe for consumption.

Furthermore, the polyurethane composition enables the design of these rollers according to specific temperature ranges, making them suitable even under extreme conditions such as hot printing presses or cold storage conveyors, without compromising their performance or longevity.

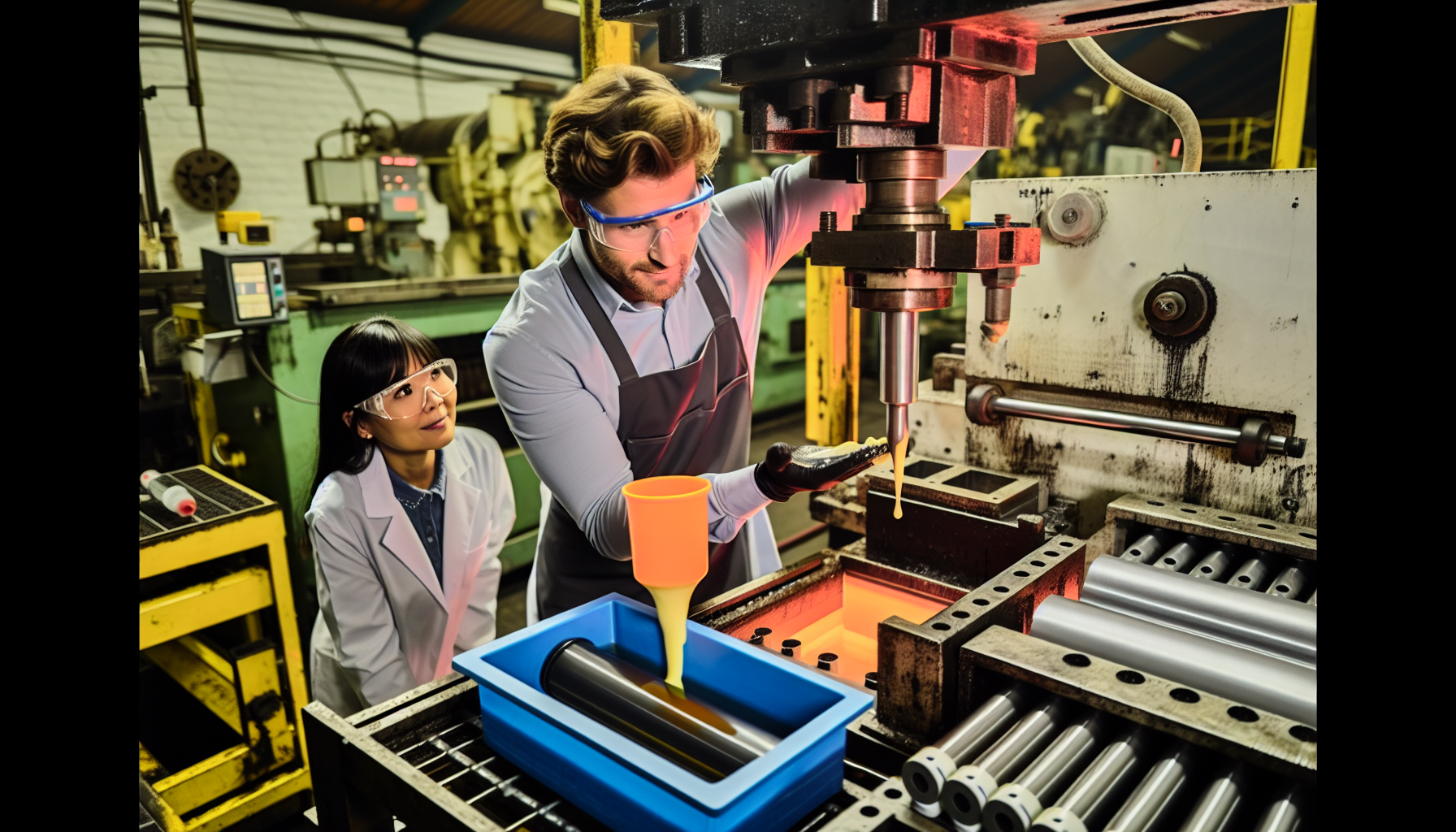

The Manufacturing Process of Polyurethane Coated Rollers

At Uniflex, Inc., we are known for our complex production process of polyurethane-coated rollers, which involves precise casting techniques and strict quality control measures. Our team of skilled professionals works diligently to deliver top-notch rollers with exceptional versatility.

Our manufacturing procedure starts with the utilization of the cost-effective method of urethane casting, ensuring long-lasting roller production. We conduct rigorous testing and inspection to maintain the high-quality standards set by our company for each manufactured roller.

With our expert knowledge and unwavering dedication to excellence, our ability to produce premium-grade versatile rollers for diverse industries is unparalleled. Every single product we design caters specifically to customer needs, resulting in enhanced operational efficiency and productivity.

In addition to producing these superior urethane products, we also provide a range of services including consultation and post-sales support, ensuring maximum utilization of our offerings by customers. This comprehensive approach, among others, such as providing economical solutions, sets Uniflex, Inc. apart within the industry.

👉Also Read: Abrasion-Resistant Polyurethane Coated Rollers: Unleash the Power of Endurance

Elevate Your Operations Today: Contact Uniflex, Inc. for Tailored Custom Cast Urethane Solutions!

At Uniflex, Inc., we recognize the transformative potential of polyurethane-coated rollers in enhancing your company’s operational efficiency. Our durable and abrasion-resistant rollers offer a myriad of advantages, coupled with versatile customization options to meet diverse industrial needs.

As industry leaders with extensive experience, we specialize in crafting custom urethane wheels and rollers for various sectors. Our unwavering commitment to quality makes us the trusted partner for businesses seeking improvement through the application of polyurethane rollers and wheels. Contact our team at Uniflex, Inc. today, and let our expertise guide you in finding the perfect solution for your business needs.