Urethane sheet stock is a versatile material that finds applications in various industries, owing to its unique properties and characteristics. Understanding its composition, features, and applications can provide valuable insights into its significance as a key component in different products and processes.

👉Also Read: Enhancing Durability: How to Get Polyurethane Sheets with Superior Abrasion Resistance

Benefits of Polyurethane Sheets

Polyurethane sheets offer several advantages across a wide range of applications due to their unique properties and characteristics. Here are some of the key advantages of polyurethane sheets:

Abrasion Resistance: Polyurethane sheets are highly resistant to abrasion, making them suitable for applications subjected to wear and tear, such as conveyor belts, seals, and rollers in industrial settings; their abrasion resistance dampens noise in various environments where noise reduction is critical.

Flexibility and Resilience: Polyurethane sheets exhibit excellent flexibility and resilience, allowing them to withstand repeated bending, stretching, and compression without losing their shape or mechanical properties. This makes them ideal for applications where durability and longevity are essential.

Chemical Resistance: Polyurethane sheets are resistant to many chemicals, oils, solvents, and fuels, making them suitable for use in environments where exposure to harsh substances is common.

Impact Resistance: Polyurethane sheets offer high impact resistance, which makes them suitable for applications requiring protection against impacts, such as in the construction of protective pads, bumpers, and liners.

Temperature Stability: Polyurethane sheets have a broad temperature range of usability, remaining stable and maintaining their mechanical properties across a wide span of temperatures, from extreme cold to high heat.

Longevity and Durability: Polyurethane sheets are known for their long service life and durability, requiring minimal maintenance and replacement compared to alternative materials, thus providing cost-effectiveness over time.

Customizable Properties: Polyurethane sheets can be formulated to exhibit specific properties tailored to the requirements of different applications, including hardness, stiffness, and elasticity, through adjustments in the formulation and manufacturing process.

Ease of Machining and Fabrication: Polyurethane sheets can be easily machined, cut, drilled, and shaped to precise specifications, allowing for efficient fabrication and customization for various applications.

Applications of Polyurethane Sheets

Polyurethane sheets find wide application across various industries due to their versatility, durability, and unique properties. Some of the common applications of polyurethane sheets include:

Seals and Gaskets: Polyurethane sheets are used to create seals and gaskets in machinery and equipment, providing a reliable barrier against leaks and preventing the ingress of contaminants such as dust, dirt, and moisture.

Conveyor Belts and Rollers: In material handling and industrial settings, urethane flat sheets are utilized to manufacture conveyor belts and rollers due to their excellent abrasion resistance, flexibility, and ability to withstand heavy loads.

Liners and Protective Pads: Standard cast urethane sheets are employed as liners and protective pads in various applications, including truck beds, chutes, hoppers, and bins, to protect surfaces from abrasion, impact, and wear.

Vibration Dampening Components: Polyurethane sheets are used to create vibration dampening components such as pads, mounts, and bushings in machinery and equipment to reduce noise, vibrations, and shock during operation.

Mold Making: Polyurethane sheets are used in mold making and casting applications to create molds for producing prototypes, parts, and products in industries such as automotive, aerospace, and consumer goods.

Architectural Molding and Trim: In the construction industry, polyurethane sheets are utilized for architectural molding and trim applications, offering a lightweight, durable, and cost-effective alternative to traditional materials such as wood and plaster.

Automotive Components: Polyurethane sheets find application in the automotive industry for producing various components including suspension bushings, bump stops, seals, gaskets, and interior trim due to their durability, resilience, and resistance to oils, fuels, and chemicals.

👉Also Read: Urethane Sheets: Why Buying Online Can Save You Time!

Custom Molded Solutions and Unique Offerings by Uniflex, Inc.

Uniflex, Inc. offers innovative solutions to minimize waste and meet precise requirements through custom urethane sheets. Our standard open-cast urethane sheets are molded in custom sizes without incurring tooling charges, thanks to our adjustable sheet molds.

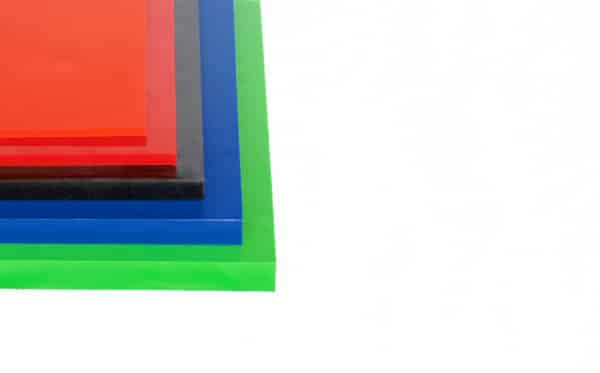

This approach allows us to produce polyurethane sheeting precisely to your required dimensions, eliminating excess material usage and mold tooling costs, and ultimately providing cost savings to our customers. With the flexibility to choose any color, durometer, and formulation, our custom urethane sheets offer unparalleled versatility.

Size Capabilities

We can produce any urethane sheet up to 50″ wide and 138″ long, accommodating various dimensions based on your specific needs. Customers commonly order larger sheet sizes with discounted rates, including widths of 12″, 24″, 36″, or 48″ by lengths of 48″, 72″, 96″, 120″, or 138″.

Tolerances for Standard Urethane Sheet

- Thickness: +/- 0.030” for 1/8” to 3/8” and +/- 0.040” for 1/2” to 1”

- Length and Width: + up to 1/2″ / – 0.000″

Precision Cast Urethane Sheets for Tighter Tolerance Requirements

For applications demanding tighter tolerance on thickness, we offer custom precision cast urethane sheets. Available in various sizes, durometers, colors, and formulations, our precision cast sheets boast superior performance in applications where rubber and similar materials fall short. With a thickness tolerance of +/- 0.007, our precision urethane sheets ensure consistent quality and reliability.

All precision urethane sheets from Uniflex, Inc. come with standard width and length tolerances of + up to 0.300” and – 0.000”, ensuring precise fit and function for your specific applications.

👉Also Read: Urethane Sheets and Industrial Applications

Unlock Superior Performance Today with Custom Urethane Sheets from Uniflex, Inc.!

Uniflex, Inc. offers a comprehensive range of custom urethane sheet solutions designed to maximize performance while minimizing waste. Our commitment to precision molding allows us to tailor polyurethane sheeting precisely to your requirements without incurring tooling charges, leading to significant cost savings for our customers. With customizable options including color, durometer, and formulation, our urethane sheets offer unparalleled versatility across diverse industries.

Whether you require standard open-cast sheets or precision-cast urethane sheets with tighter tolerances, Uniflex, Inc. delivers consistent quality and reliability. Explore our range of custom molded polyurethane solutions and experience the unique offerings that set us apart in the industry. Let Uniflex, Inc. be your trusted partner for all your urethane sheet needs. Contact Uniflex, Inc. now at 248-486-6000 to explore the endless possibilities for your unique applications.