When it comes to maintaining your Polaris plow, the cutting edge is key. The right choice between steel or polyurethane edges impacts not just clearing snow efficiently but also your plow’s longevity. Our guide cuts straight to the chase, detailing the benefits, compatibility, and installation methods for your Polaris plow cutting edge, helping you make the best decision without any fuss.

Key Takeaways

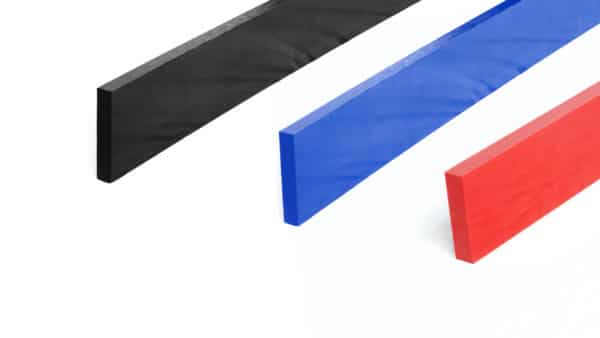

- Polyurethane and hardened steel cutting edges offer different benefits for snowplows, with poly edges providing a cleaner sweep and less surface damage, whereas steel edges resist bending. The right choice depends on the application, blade size, and compatibility with Polaris plow models.

- Installing a cutting edge on a Polaris plow can enhance snow-clearing efficiency, reduce wear and tear, and improve traction and control. To ensure safety and optimal performance, proper installation techniques and regular maintenance such as cleaning, inspections, and timely replacements are crucial.

At Uniflex, Inc., we provide high-performance urethane plow-cutting edges with a range of blade thickness options to suit different equipment and plowing requirements. Rely on our expertise in polyurethane products to help you choose the perfect edge for commercial and residential applications.

👉Also Read: Find the Best Customized Urethane Products — Shop Uniflex

Choosing the Right Cutting Edge Technology for Your Polaris Plow

Choosing the right cutting edge for your Polaris plow involves careful consideration of the following factors:

- Blade size

- Blade weight

- Material

- Cutting edge condition

- Angle adjustment

The correct cutting edge is fundamental to the efficiency and longevity of your plow setup.

Materials like polyurethane, used in the manufacturing of custom polyurethane wheels have been shown to offer durability and longevity. Polyurethane is notably resistant to harsh chemicals, including acids and solvents, making it an ideal choice for environments where exposure to such substances is common. For instance, cutting edges for Polaris 9 bolt blades can offer a longer lifespan compared to steel ones. When considering an upgrade, an existing wheel made of polyurethane can be a great choice, especially when opting for polyurethane wheels.

Steel vs. Polyurethane Cutting Edges

While steel cutting edges are commonly used due to their multi-purpose nature and resistance to bending, upgrading to a new polyurethane edge offers superior performance on delicate surfaces.

These polyurethane edges not only improve snow-clearing efficiency by providing a cleaner sweep and preventing damage to surfaces like concrete or asphalt. Moreover, polyurethane edges are preferred for their:

- Noise reduction capabilities

- Ability to maintain shape

- Ability to absorb impacts from hidden objects, thereby lessening shock and vibration transmitted to the snowplow’s machine and frame.

Durability considerations reveal that UHMW polyethylene wear bars can enhance a Polaris plow’s performance, particularly for back dragging. In comparison, the polyurethane edges can significantly increase the longevity of the plow due to their effectiveness in absorbing impacts and preventing frequent wear and tear, making them a more cost-effective and durable option.

Determining the Proper Size

The width of the cutting edge should match the width of your Polaris plow to ensure full coverage and effective snow removal. But it’s not just about width. The correct size of the cutting edge needs to complement the size and weight of the vehicle used for snow plowing to maintain proper balance and performance.

Blade height is also essential when determining the cutting-edge size to ensure the plow operates at an optimal height to effectively clear snow without causing surface damage or wear to the plow. Beware, a cutting edge that is too tall can lead to inadequate clearance from the ground, impacting snow removal efficiency and increasing wear on the plow.

Compatibility with Polaris Models

Before purchasing a cutting-edge kit, it’s crucial to check its compatibility with your Polaris model. For instance, the Polaris Glacier Plow 72” Cutting Edge Kit is compatible with a variety of Polaris models, including selections from the General and Ranger series produced between 2014 and 2023.

Upgrading Your Polaris Plow with a Cutting-Edge

Upgrading your Polaris plow with a cutting edge isn’t just about enhancing its look. It’s about improving its performance, durability, and longevity. A Polaris plow upgrade with a quality cutting edge provides increased durability over standard options, as high-grade materials such as hardened steel or polyurethane offer a longer service life.

Upgrading the plow with a cutting edge may also involve adjustments like changing plow stop blocks to make the plow more or less aggressive for different snow conditions.

Improved Snow Clearing

A cutting edge isn’t just a tool for breaking through the snow. It can also determine how clean and efficient your snow clearing will be. For instance, installing a polyurethane cutting edge on a Polaris plow can lead to a cleaner removal of snow, avoiding the residue often left behind by steel blades. Polyurethane cutting edges also minimize the risk of surface damage, making them ideal for use on properties such as shopping malls and residences.

Adjusting the cutting edge, like skid shoe height, is a method of preventing damage to driveways and enhances the effectiveness of snow removal. Cutting the bottom corners of the cutting edge at a 45-degree angle is a useful technique to prevent damage to adjacent surfaces such as lawns during installation.

Reduced Wear and Enhanced Tear Resistance

One of the main benefits of upgrading your Polaris plow with a cutting edge is the potential to reduce wear and tear. A hardened steel or polyurethane cutting edge can reduce the frequency of replacements by offering increased resistance to wear compared to standard Polaris scraper bars.

Notably, the wear bar, which acts as a cutting edge, is reversible and can be flipped to extend its life and protect the plow blade from excessive wear. This means you can get more usage out of your cutting edge, thus saving you time and money on replacements.

Enhanced Traction and Control

Enhanced traction and control are two major benefits you can expect when you upgrade your Polaris plow with a cutting edge. Polyurethane cutting edges improve traction by flexing to adapt to uneven surfaces, such as concrete and speed bumps. The flexibility of polyurethane edges also aids in maneuvering the plow over obstacles, enhancing control during snow removal operations.

On the other hand, hardened steel cutting edges add weight, which can enhance downward pressure and improve traction when plowing. So, whether you’re dealing with a smooth concrete driveway or a rough, uneven surface, a cutting edge can help you maintain control and effectively clear the snow.

👉Also Read: Purchase Your Polyurethane Plow Edge This Winter

Installation Tips for Polaris Plow Cutting Edges

Once you’ve chosen the perfect cutting edge for your Polaris plow, the next step is installation. But before you get started, you need to gather the necessary tools, including wrenches and protective gloves.

Always wear safety glasses and gloves when installing the cutting edge to prevent injuries from any flying metal shards or debris.

Tools and Materials Needed

To install your cutting-edge, you’ll need the following tools:

- Various sockets (13mm, 15mm, 17mm, 19mm)

- An adjustable wrench

- Pliers

- A ratchet

- Potentially a torque wrench for proper tightening

Carriage bolts for the cutting edge should be grade 5 or higher and accompanied by nylon locking nuts, ensuring a non-marking installation.

Don’t forget about personal protection during the installation. Safety glasses and nitrile gloves are a must to protect against potential hazards.

Step-by-Step Installation Guide

Installing a Polaris plow cutting edge is a simple task when you adhere to the correct procedure. Follow these steps:

- Begin by removing the existing cutting edge from your snow plow.

- Place the old blade onto the new one and mark the hole pattern onto the new blade using a marker.

- Drill corresponding holes in the new blade based on the traced bolt pattern.

- Securely attach the new blade to the plow, with the old blade positioned on top to provide additional support. Alternatively, you can utilize large washers for added reinforcement.

- To prolong the lifespan of your cutting edge, consider flipping it 180 degrees to utilize the opposite side once wear occurs. Alternatively, you can adjust the bolt pattern to shift the wear strip downwards.

By following these straightforward steps, you can easily install your Polaris plow cutting edge for optimal performance.

Safety Precautions

Safety should be your top priority during the installation process. When servicing the Polaris vehicle, it is important to wear safety glasses and nitrile gloves to protect against potential hazards. During the installation and use of a Polaris plow cutting edge, wearing a winter-rated helmet, insulated gloves, warm clothing, and slip-resistant boots is recommended to enhance safety.

A thorough inspection of the plow system should be conducted before, during, and after use, checking for any loose parts, winch damage, snow or ice build-up, and ensuring adequate load capacity, to maintain a safe installation and operation environment.

Maintenance and Care for Your Polaris Plow Cutting Edge

Now that your cutting-edge is installed, how do you ensure it lasts as long as possible? Maintenance and care are crucial.

Inspect your plow’s cutting-edge frequently to ensure it’s in good condition and to identify any potential issues early. Here are some steps to follow:

- Clean your cutting edge after each use to prevent rust and corrosion.

- Tighten any loose bolts.

- Replace bolts that show signs of wear to avoid damage to the cutting edge or plow.

Regular Inspections

Regular inspections of the cutting edge can prevent damage to the plow base angle and ensure its optimal performance. Contractors should measure the height of their cutting edge before the season begins and track wear regularly to determine if a change is needed.

Inspecting the Polaris plow system before, during, and after use is important to ensure readiness for the next snow removal task. Conducting regular inspections is essential, paying attention to potential issues such as loose parts, winch damage, and accumulation of snow or ice.

Cleaning and Storage

Cleaning your cutting edge after each use isn’t just about maintaining its appearance. It’s about preventing rust and corrosion that can shorten its lifespan. Polyurethane cutting edges are advantageous for storage because they can regain their original shape after impact, which improves longevity and function preservation while stored.

When storing your plow, use a board, mat, or cardboard beneath the lowered blade to protect your garage floor from potential marks or damage. Be sure to store the cutting edge in a dry place to prevent rust and corrosion when not in use.

Replacing a Worn Cutting Edge

Eventually, your cutting edge will wear out and need replacement. But how do you know when it’s time for a new one? Look for signs of significant wear or damage, such as deep gouges, bent blades, or excessive thinning, which indicate the need for replacement. An accumulation of debris on the blades may also signal the need for replacing the cutting edge.

To extend the life of the cutting edge, the wear bar or cutting edge on the Polaris plow blade is reversible and can be flipped for continued use before a replacement is warranted. After installing a new cutting edge, it’s recommended to back-drag the Polaris plow for a few hundred feet to smooth the back edge, setting it up for first use.

👉Also Read: The Top 4 Industries That Benefit From Custom Polyurethane Products

Uniflex, Inc.’s Custom Polyurethane Wheels and Urethane Plow Cutting Edge

Elevate your snow plowing game with Uniflex, Inc.’s top-tier urethane plow cutting edge. With over four decades of expertise in polyurethane roller manufacturing, Uniflex, Inc. delivers high-performance urethane resins, including FDA-approved formulations and equivalents to Vulkollan®.

Guide for Choice of Blade Thickness

Choosing the right blade thickness is crucial to ensure optimal performance. Uniflex, Inc. provides a comprehensive guide to help you make the right choice based on your specific plowing needs and equipment. Whether you’re doing:

- Light work with ATVs, UTVs, small tractors

- Standard work with larger tractors, ATVs, UTVs

- Commercial work with trucks and commercial vehicles

- Heavy work with large/heavy equipment, trucks, and/or excessive use

There’s a poly blade thickness that’s right for you, even if you’re considering a steel blade, offering tear resistance as an added benefit.

Versatile and cost-effective, our cutting edges find applications across various sectors. From commercial plowing on airports and roadways to residential plowing on driveways and sidewalks, Uniflex, Inc. has you covered. Our products are compatible with a range of equipment, including ATVs, UTVs, tractors, and trucks.

Interested in learning more about Uniflex, Inc.’s urethane plow cutting edge or need assistance with your project? Feel free to give us a call at 248-486-6000 or contact us directly through our website. We have an experienced team that is more than willing to help you out with whatever project you are working on!