In the world of industrial machinery and equipment, durability and efficiency are paramount. This is where custom-molded urethane and rubber products come into play, offering versatile solutions for a wide range of applications.

At Uniflex, Inc., we stand at the forefront of this dynamic industry, delivering innovative urethane solutions to meet the evolving needs of our customers. With decades of expertise, Uniflex, Inc. has established itself as a trusted partner for businesses seeking high-performance polyurethane and urethane products.

In this blog, we’ll delve into the key advantages of utilizing polyurethane and urethane rollers in various industries, from material handling to manufacturing processes.

👉Also read: Enhance Durability and Flexibility with Custom Molded Urethane Elastomers

Key Benefits of Polyurethane Rollers

Here are some key advantages of using polyurethane rollers:

A. Durability and Longevity

Polyurethane rollers offer an exceptional level of durability and longevity that sets them apart in industrial applications. Their resistance to abrasion and wear ensures they can endure the harshest conditions, making them ideal for tasks involving constant movement, heavy loads, and rough surfaces.

This attribute translates to reduced maintenance and replacement costs, providing a cost-effective solution over time for many industries. The remarkable tensile strength and abrasion resistance of polyurethane rollers enable them to withstand dynamic loads without experiencing deformation or failure, contributing to their prolonged lifespan.

Additionally, their low permanent set – the tendency to deform under load – ensures consistent performance over extended periods, maintaining efficiency without compromising their structural integrity.

B. Customization for Specific Requirements

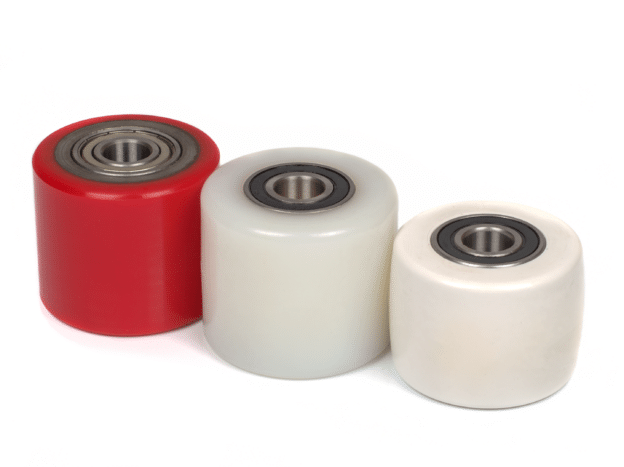

The ability to customize polyurethane rollers to meet unique industry needs is a significant advantage. Manufacturers can tailor these rollers to precisely match specific equipment and machinery specifications. This adaptability extends beyond size, length, and shape, encompassing different physical properties like hardness, resilience, and load-bearing capacity. This flexibility enables the creation of rollers that seamlessly integrate into diverse machinery setups, ensuring optimal performance and efficiency for each application.

C. Enhanced Performance in Various Environments

Polyurethane rollers excel in a wide range of environments, showcasing remarkable adaptability and resilience. Their resistance to solvents, chemicals, and moisture makes them suitable for applications in both wet environments and harsh conditions. This feature is especially crucial in industries such as food processing and packaging, where sanitation and hygiene are paramount.

Regardless of the challenges posed by the environment, polyurethane rollers maintain their reliability, ensuring smooth and consistent operations. This enhanced performance translates to reduced downtime and maintenance costs, contributing to improved overall efficiency in industrial settings.

Versatility of Polyurethane Rollers in Industries

The versatility of polyurethane rollers is one of their most significant advantages, as they find applications across a wide range of industries. Here’s a closer look at how these rollers are utilized in various sectors:

A. Material Handling and Transport

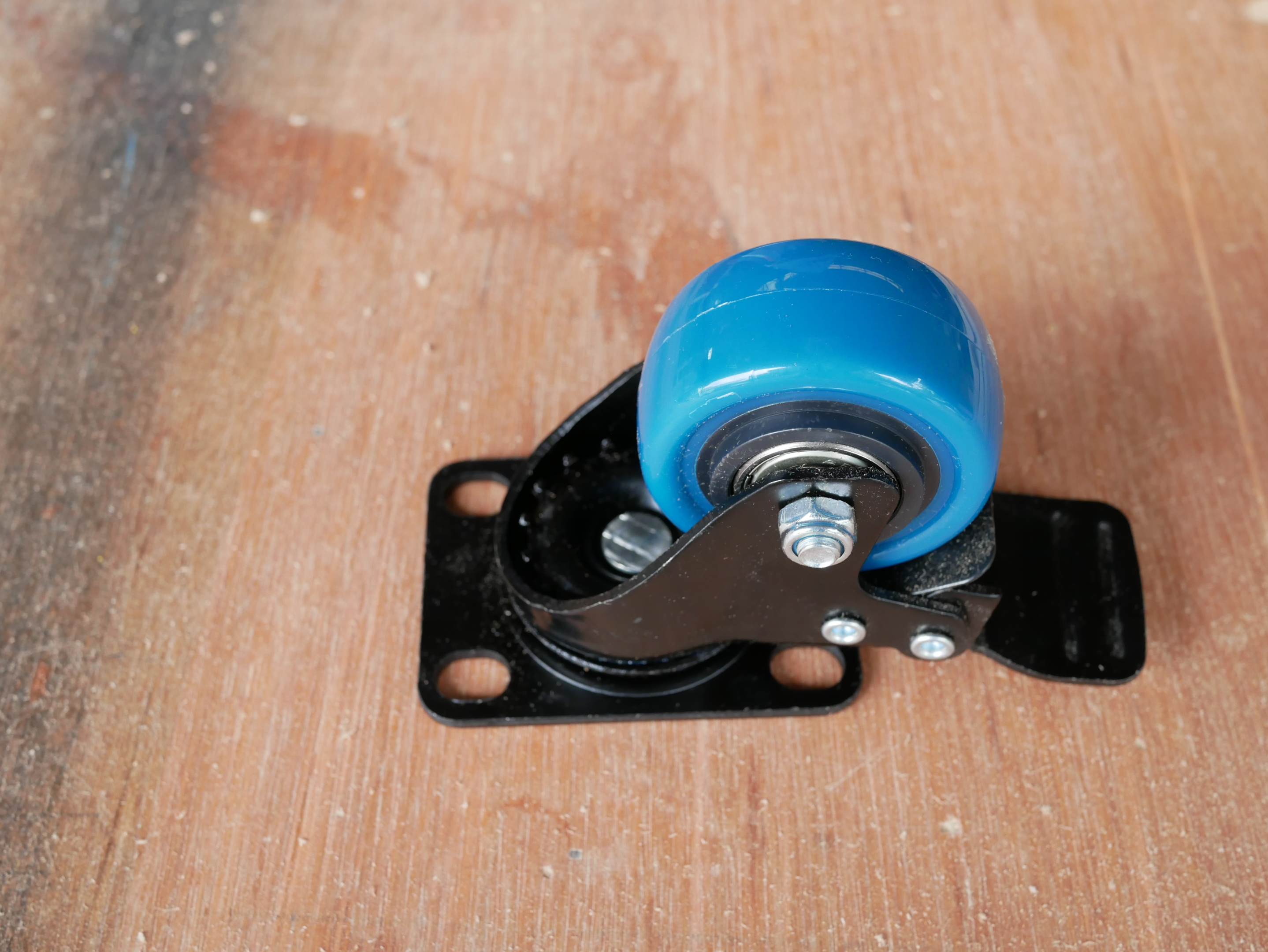

Polyurethane rollers play a vital role in the domain of material handling and transport. They are integral components of conveyor systems, where they facilitate the smooth movement of goods and materials. By incorporating polyurethane rollers into conveyor systems, industries ensure efficient operations with reduced friction and wear. These rollers contribute significantly to the packaging and production process and processes, where they aid in maintaining a consistent flow of materials, reducing the likelihood of jams or disruptions in material transport.

B. Machinery and Equipment Applications

The adaptability of polyurethane rollers extends to various machinery and equipment applications. They find utilization in drive rollers, enabling the movement of machines and equipment with precision. In this role, they ensure smooth and controlled motion, enhancing the overall efficiency of the machinery. Moreover, polyurethane rollers serve as guide rollers and idler rollers, offering precise alignment and stability to components. Their ability to be custom-manufactured according to specific equipment requirements further enhances their versatility in diverse settings.

C. Printing and Manufacturing

The versatility of polyurethane rollers is evident in the printing and manufacturing sectors. They are widely used in printing rollers, facilitating consistent ink distribution across various substrates. Their exceptional wear resistance ensures prolonged and reliable performance, reducing the need for frequent replacements. This resilience contributes to the production processes by maintaining a consistent quality output over time. With their ability to adapt to different industries’ requirements, polyurethane coated rollers can find application in a multitude of manufacturing needs, highlighting their versatility and efficiency across various sectors.

Advanced Features of Urethane Conveyor Rollers

Here are some of the advanced attributes of urethane conveyor rollers:

A. High Friction and Improved Traction

Urethane feed rollers also bring advanced features that enhance material movement and handling. Their inherent high friction properties feed rollers provide an enhanced grip on materials, ensuring smooth transport without slippage. This improved traction contributes to the precise positioning and handling of goods along conveyor systems. Industries benefit from reduced incidents of material shifting or misalignment, which can lead to production disruptions or damage.

B. Low Cost and Cost-Effectiveness

Urethane rollers not only offer exceptional performance but also present economic advantages. They provide reliable and consistent performance at a competitive price point compared to alternatives like metal rollers. These cost savings extend beyond the initial purchase, as urethane rollers exhibit longevity and reduced wear, resulting in fewer replacements and maintenance expenses. Industries can optimize their operations with cost-effective solutions without compromising on performance.

C. Custom Design and Manufacturing Process

The customizability of urethane conveyor rollers is a key factor in their appeal. Urethane roller manufacturers offer fast turnaround times, ensuring that industries can meet their production schedules without delays. Moreover, the manufacturing process of urethane also allows for the incorporation of grooves, bearings, and other features tailored to specific needs.

This level of customization ensures that the urethane rollers precisely match equipment requirements and industry standards, contributing to efficient machine operations and optimized performance. Whether it’s a unique design, specific size, or specialized features, the customizability of urethane rollers makes them a versatile solution for various industrial applications.

Comparing Polyurethane and Urethane Rollers with Other Roller Materials

Polyurethane vs. Rubber Rollers

When comparing polyurethane and natural rubber rollers, the advantages of polyurethane become evident. Polyurethane offers improved durability, wear resistance, and an extended lifespan over natural rubber. This makes polyurethane rollers a superior choice for industries seeking longevity and consistent performance in their equipment. The enhanced properties of polyurethane translate to reduced downtime, maintenance, and replacement costs, providing an efficient solution for various applications.

Polyurethane vs. Metal Rollers

Polyurethane rollers exhibit distinct benefits when compared to metal rollers. Firstly, a polyurethane roller’s lower weight contributes to improved handling and reduced strain on equipment. Additionally, a polyurethane roller’s natural resistance to corrosion eliminates the need for protective coatings, unlike steel rollers that are susceptible to rust. The versatility of polyurethane allows it to outperform metal alternatives in terms of noise reduction and impact absorption, resulting in smoother and quieter operations.

Polyurethane vs. Plastic Rollers

Comparing polyurethane to plastic rollers underscores the former’s superior load-bearing capacity and wear resistance. Polyurethane rollers possess a remarkable ability to withstand heavy loads without compromising performance. Furthermore, the exceptional wear resistance of polyurethane ensures a prolonged lifespan and consistent functioning, even in demanding applications. This durability and reliability make polyurethane rollers a prime choice for industries that require robust and enduring equipment solutions.

👉Also read: The Top 4 Industries That Benefit From Custom Polyurethane Products

Uniflex, Inc.: Your Partner in Precision Polyurethane Rollers

In the ever-evolving landscape of industrial equipment, conveyors, and machinery, precision and performance are non-negotiable. Polyurethane-coated rollers provide the ideal solution to enhance durability, efficiency, and longevity. Their versatility spans across various industries, from material handling to manufacturing processes. As urethane roller manufacturers, we understand the significance of choosing the right components for your machinery.

At Uniflex, Inc., we offer custom urethane products tailored to your specific needs, ensuring optimal performance and efficiency. Embrace the advantages of polyurethane rollers and experience an upgrade in your industrial operations. Contact us today for expert assistance in achieving precision-engineered excellence.