Custom urethane parts are a testament to versatility in manufacturing. The magic lies in the chemical reaction that transforms raw materials into a resilient force that can withstand the harshest conditions. The choice of material in manufacturing is paramount, and custom urethane parts stand out as the go-to option for jobs that demand excellence.

At Uniflex, Inc., we specialize in crafting these robust components, tailored to withstand the rigors of the most demanding applications. Our commitment to maximizing durability begins with the careful selection of urethane formulations, ensuring that each custom part is engineered to exceed industry standards. Whether you’re navigating extreme temperatures, corrosive environments, or facing abrasive wear, our custom urethane parts provide a reliable solution for your toughest challenges.

In this blog, we’ll delve deeper into the remarkable world of custom urethane parts, examining their diverse benefits and applications that set new standards for resilience in various industrial settings.

👉Also Read: Precision Engineered Conveyor Rollers: The Advantages of Urethane and Polyurethane

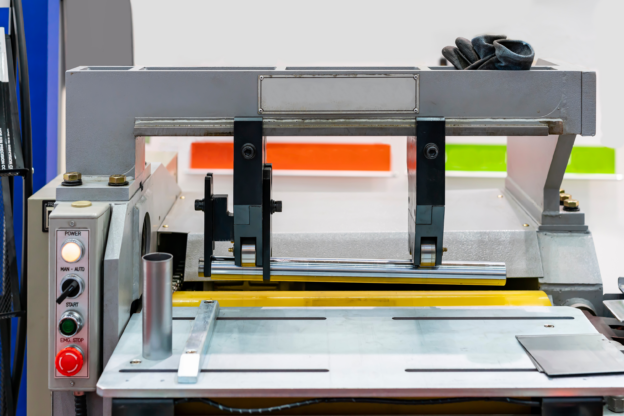

Surface Saver Cutting Edges: Unmatched Durability

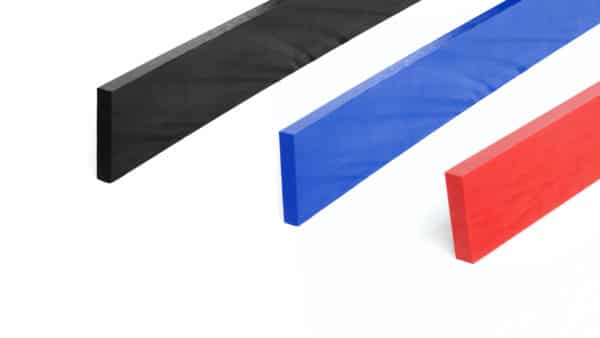

Urethane cutting edges offer several benefits that make them a popular choice in various industries. One key advantage lies in their unique feature of having two usable wear edges, which significantly enhances their efficiency and longevity.

Two Usable Wear Edges

Extended Lifespan: The dual wear edges of urethane cutting blades provide twice the usable surface area compared to traditional single-edge blades. This extends the lifespan of the blade, reducing the frequency of replacements and contributing to cost savings for businesses.

Increased Productivity: The ability to flip the blade and use the opposite edge effectively doubles the time between maintenance cycles. This feature is particularly beneficial in industries where continuous operation is critical, as it minimizes downtime for blade changes.

Exceptional Service Life

Abrasion Resistance Urethane cutting edges are known for their exceptional abrasion resistance. This makes them well-suited for applications where the blade comes into contact with abrasive materials or surfaces, such as concrete, asphalt, or other challenging environments.

Impact Resistance: Urethane material also exhibits excellent impact resistance, ensuring that the cutting edge can withstand sudden shocks and heavy impacts without chipping or breaking. This robustness contributes to a longer service life and reduces the need for frequent replacements.

Polyurethane Plow Edge: Ideal for Snow Plowing Applications

Snow plowing takes center stage as we explore the prowess of polyurethane snow plow blades. Addressing the specific needs of snow plowing applications, these urethane quality blades outlast rubber counterparts, ensuring not just efficient snow removal but also longevity in maintaining roadway markings. It’s a win-win, translating from snow plowing application to cost savings and reduced downtime for trucks braving winter challenges.

Custom Urethane Products for a Variety of Industries

Custom urethane products offer versatile solutions across a spectrum of industries, showcasing their adaptability in numerous applications. From conveyor belts to industrial components, cast urethane products demonstrate their efficacy in diverse settings. Notably, the use of custom urethane can significantly reduce maintenance costs across multiple industries due to its durability, abrasion resistance, and impact resistance. This translates into extended product lifespan, minimizing downtime and replacement frequency.

In applications such as snow plows and road maintenance equipment, custom urethane products play a crucial role in ensuring air quality by gentler contact with surfaces and reducing damage to roadway markings. This unique combination of versatility, cost-effectiveness, and environmental considerations makes custom urethane products a preferred choice for industries seeking reliable and efficient solutions.

Why Urethane Over Other Materials?

A comparative lens is cast on urethane versus other materials, and the verdict is clear. Wider widths and the right material are not just preferences; they are prerequisites for exceptional performance. Polyurethane emerges as the hero, showcasing unparalleled properties, especially when the going gets tough.

Surface Saver Cutting Edges for Various Applications

The versatility of surface saver cutting edges takes the stage once more. Their application extends beyond expectations, finding a home in components, rollers, and more. With different sizes and thickness options available, customization isn’t just a feature; it’s a promise of precision tailored to diverse needs.

👉Also Read: Experience the Excellence of Cast Urethane Products for Your Unique Needs

Maximizing Durability: Uniflex, Inc. – Your Trusted Partner for Custom Urethane Solutions

As your trusted partner in custom urethane solutions, Uniflex, Inc. is here to elevate your industrial performance with precision, resilience, and innovation. Explore the remarkable world of custom urethane part with us and experience the difference that durability can make in your applications. Contact us today at sales@uniflexinc.com or 248-486-6000 for more information.