Custom molded rubber parts are essential components in countless industries, from automotive and aerospace to robotics, mining and industrial machinery. Their versatility, durability, and ability to meet precise specifications make them indispensable in modern manufacturing.

In this guide, we’ll take you beyond the basics, exploring the design principles, advanced manufacturing techniques, and real-world applications of custom molded rubber parts. You’ll also discover the types of materials available, key benefits, and how these engineered solutions can enhance performance, longevity, and efficiency in your products. Whether you’re an engineer, designer, or procurement professional, this guide provides the insight needed to make informed decisions about rubber and urethane components.

Ready to transform your designs with precision-engineered rubber solutions? At Uniflex, Inc. in Brighton, Michigan, we specialize in delivering custom molded rubber products that meet the most exacting specifications, from prototype to full-scale production. Our team combines advanced manufacturing techniques with deep material expertise to help your products perform better, last longer, and stand out in any industry. Contact us today at 248-486-6000 to discuss your project and discover how Uniflex, Inc. can provide the custom solutions your designs deserve.

👉Also Read: The Engineer’s Guide to Exploring High-Performance Castable Urethane Elastomers

Understanding Custom Molded Rubber Parts

Custom rubber molded parts are precision-engineered components designed to solve problems that standard parts simply can’t address. Unlike off-the-shelf alternatives, these components are manufactured to your exact specifications—whether that means unusual geometries, specific durometer ratings, chemical resistance profiles, or performance characteristics that push the boundaries of conventional rubber products.

What makes custom molding so powerful is the precision control over multiple variables simultaneously. Engineers can specify exact shore hardness for optimal compression, select compounds that withstand temperatures from -60°F to 500°F, incorporate metal inserts for structural integrity, and achieve tolerances measured in thousandths of an inch. This level of customization transforms rubber from a generic material into a strategic solution for critical applications.

The versatility extends beyond material properties to manufacturing capabilities. Modern molding processes—including compression, transfer, and injection molding—can produce everything from tiny O-rings weighing fractions of an ounce to heavy-duty industrial mounts exceeding 50 pounds. Whether you need vibration isolators for aerospace equipment, FDA-compliant gaskets for food processing, or oil-resistant seals for hydraulic systems, custom molding delivers components that perform reliably under your specific operating conditions.

This isn’t just about making rubber parts that fit—it’s about engineering solutions that extend equipment life, reduce maintenance costs, prevent costly failures, and often enable product innovations that wouldn’t be possible with standard components. When your application demands more than what’s available in a catalog, custom molded rubber parts bridge the gap between what exists and what you need.

👉Also Read: Molded Urethane: 10 Facts and 5 Myths Every Manufacturer Should Know

Advantages of Custom Rubber Molding

Superior Durability Where It Matters Most

Custom molded rubber components outlast generic alternatives because they’re engineered for your specific operating environment. When a part is formulated to resist the exact chemicals it will encounter, molded to the precise hardness your application demands, and designed with the correct geometry to distribute stress, it doesn’t just last longer—it performs consistently throughout its service life.

Whether facing continuous vibration in mining equipment, thermal cycling in automotive applications, or aggressive chemical exposure in processing plants, properly specified custom rubber parts maintain their seal integrity, dimensional stability, and mechanical properties far beyond standard components.

Design Flexibility That Solves Complex Challenges

Custom molding unlocks design possibilities that off-the-shelf parts can’t match. Need to consolidate multiple components into a single molded part? Possible. Require metal inserts overmolded for secure attachment? Standard practice. Want to combine different durometers in one component for varying flexibility zones? Achievable. This design freedom means engineers can optimize performance rather than compromise their designs around available parts. Modifications can be implemented through mold adjustments without retooling entire production lines, allowing iterative improvements and rapid response to evolving requirements.

Manufacturing Efficiency and Cost Control

While custom molding requires upfront tooling investment, the economics become compelling at scale. High-volume production runs leverage automated processes that deliver consistent quality with minimal labor costs. Material utilization rates often exceed 95%, with scrap and flash being recyclable back into production. The elimination of secondary operations—like trimming, bonding, or assembly steps required with standard parts—reduces touch time and associated labor costs. For many applications, the total cost of ownership favors custom molding once you factor in extended service life, reduced failure rates, and elimination of emergency replacements.

Environmental Advantages

Modern rubber molding operations generate significantly less waste than subtractive manufacturing methods. Excess material from runners and flash is reground and reintroduced into production compounds. Many facilities have achieved near-zero landfill status by implementing closed-loop material systems. Lower cure temperatures compared to thermoplastic processing reduce energy consumption, while longer part life cycles mean fewer replacements and reduced material consumption over time.

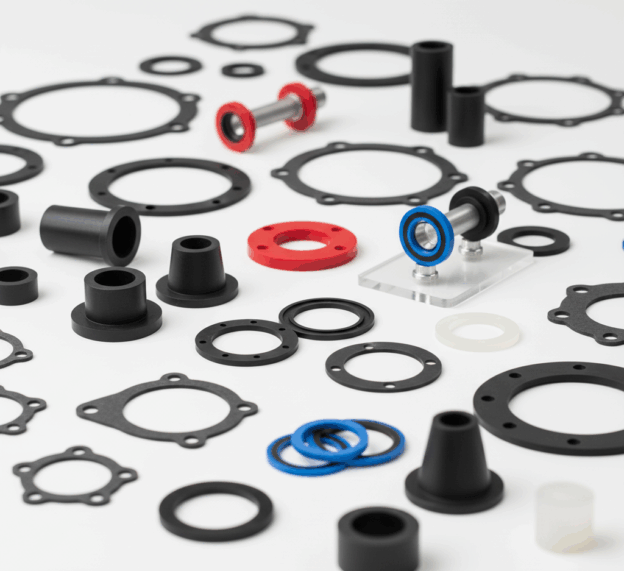

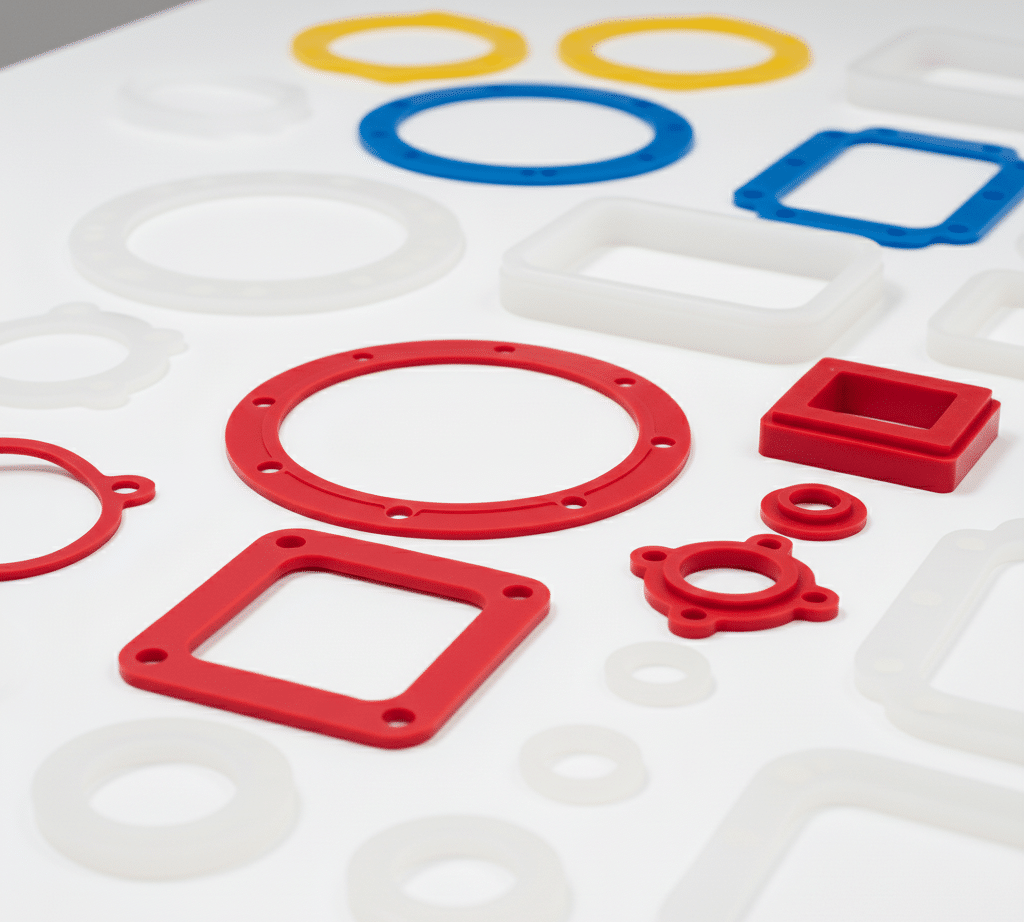

Types of Custom Molded Rubber Parts

Custom molded rubber parts are engineered to meet precise functional requirements across a variety of industries, from automotive and aerospace to mining, robotics, and marine applications. Each type of component serves a unique purpose, helping equipment operate efficiently, safely, and reliably.

- Seals and Gaskets: Essential for preventing leaks and maintaining pressure, these components ensure airtight or watertight integrity in engines, hydraulic systems, and industrial machinery. In the marine and oil & gas industries, specialized seals withstand harsh environments, including exposure to saltwater, chemicals, and extreme temperatures.

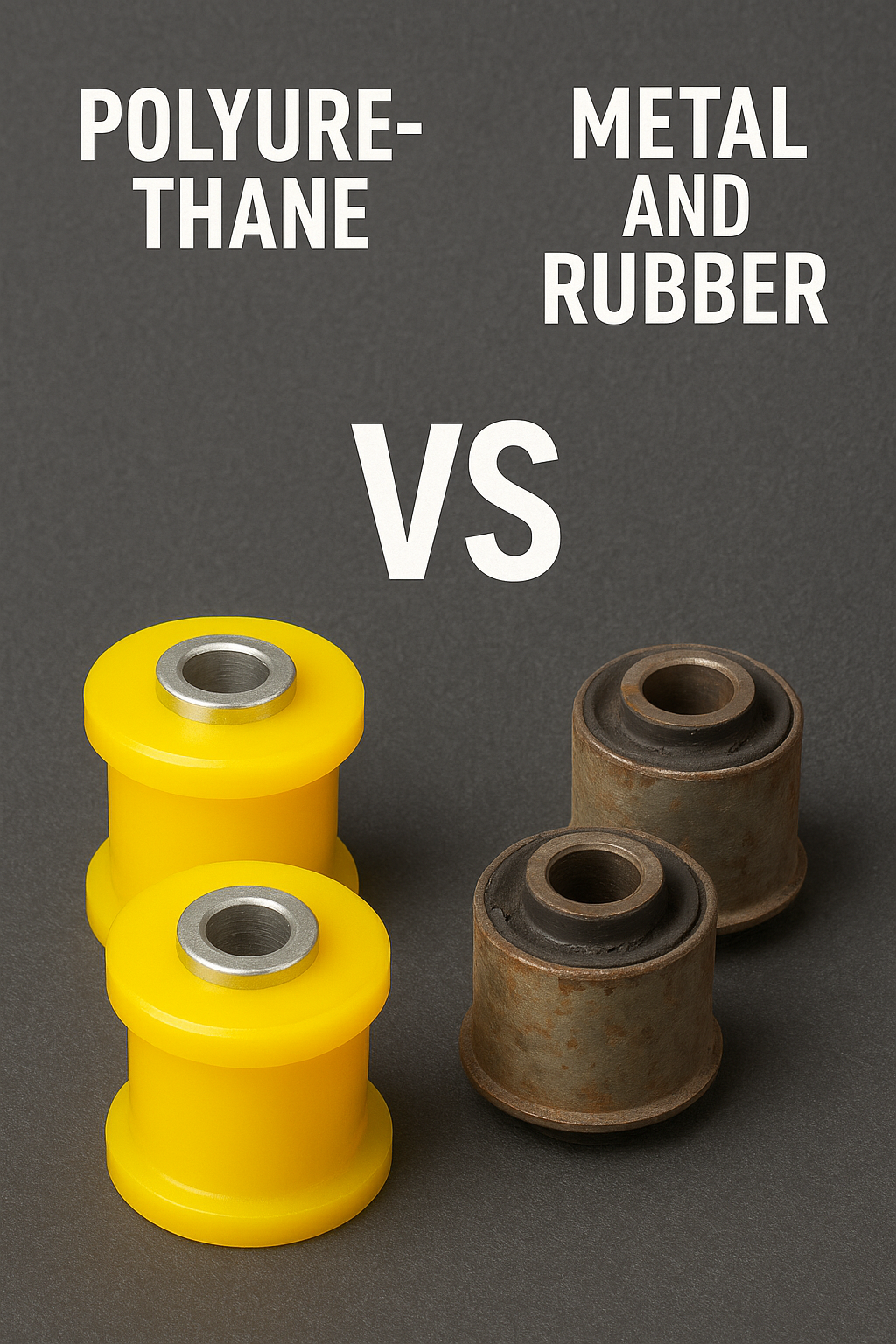

- Bushings: Bushings reduce friction between moving parts, improving operational efficiency and extending equipment life. They are widely used in automotive suspension systems, robotics joints, and heavy machinery in mining and material handling operations.

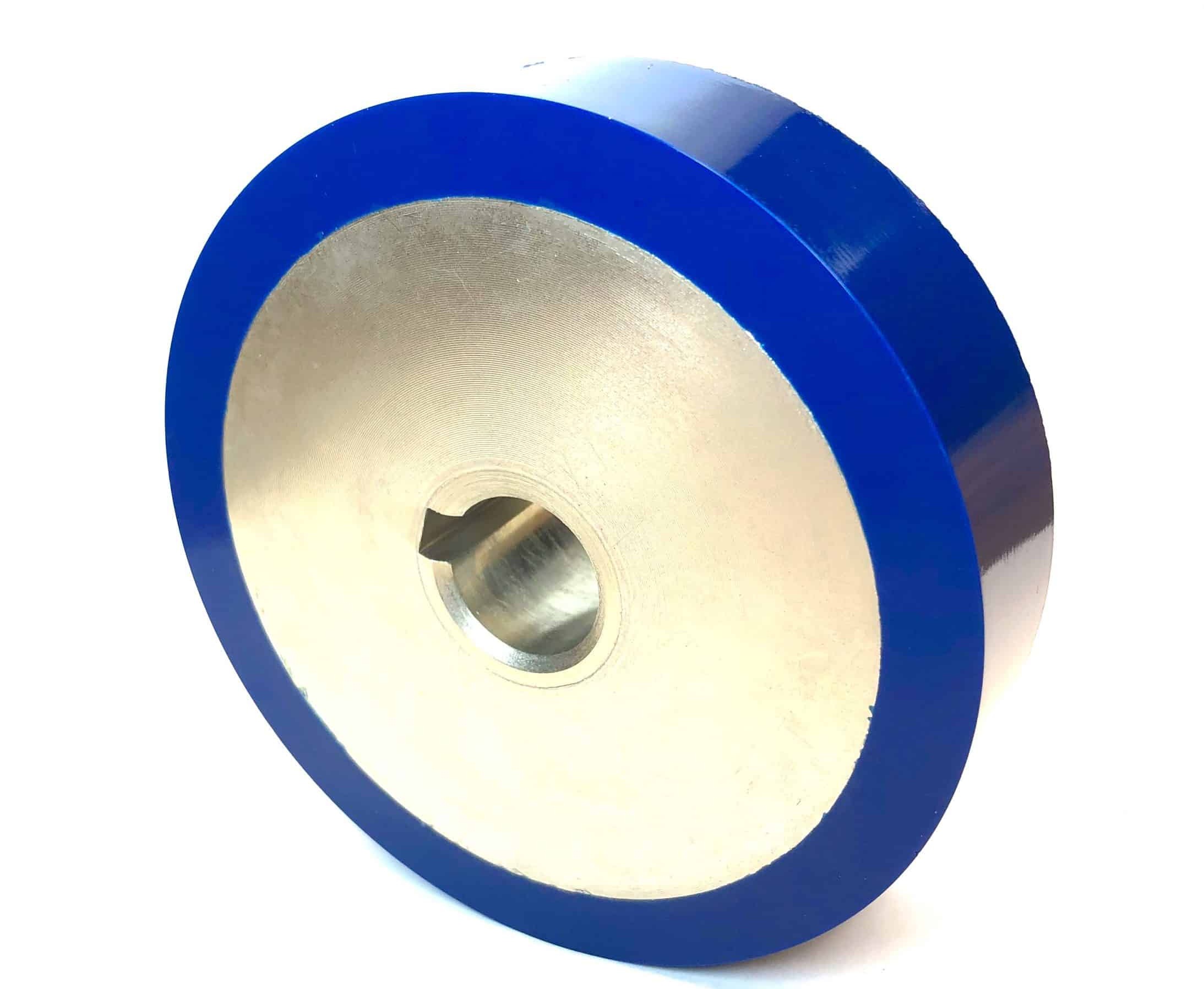

- Rollers: Custom molded rollers facilitate smooth movement of materials in manufacturing and processing systems. In automotive assembly lines, mining conveyors, and industrial printing equipment, rollers handle high loads while reducing wear and improving consistency.

- Grips and Handles: Ergonomically designed grips enhance user comfort and control on tools, machinery, and equipment. Industries such as material handling, construction, and robotics rely on molded grips to improve operator performance and reduce fatigue.

- Surface Protection Parts: Rubber components such as pads, bumpers, and guards protect delicate surfaces from impact, abrasion, or scratches during handling, transport, and assembly. These parts are critical in marine equipment, aerospace components, and high-precision machinery.

- Vibration Dampeners and Mounts: These parts absorb shocks, vibrations, and noise, protecting sensitive machinery and improving operational stability. They are especially important in robotics, automotive engines, industrial compressors, and offshore equipment.

- Specialty Parts: Custom molded components can be tailored for extreme environments, including high-temperature, chemical-resistant, or FDA-compliant applications. Examples include mining equipment bushings, marine-grade seals, and urethane rollers for robotics or material handling systems.

Each custom molded rubber part is designed to meet the specific demands of its application, ensuring reliable performance, longer equipment life, and enhanced operational efficiency. By choosing the right material and design for your industry, you can reduce downtime, lower maintenance costs, and achieve superior results across your operations.

👉Also Read: Is Polyurethane Toxic to Skin? What You Need to Know

Key Industries Utilizing Custom Molded Rubber Parts

Custom molded rubber and urethane parts are integral to a wide range of industries, providing durable, precise, and cost-effective solutions for demanding applications. Uniflex, Inc. has been serving these sectors since 1979, supplying components that improve performance, reduce maintenance, and extend equipment life. Key industries include:

- Automotive: Rubber bushings, seals, and rollers are critical in suspension systems, engine components, and material handling equipment, ensuring smooth operation and long-lasting performance.

- Aerospace: Custom molded parts are used for vibration dampening, sealing, and surface protection in aircraft systems, where precision and reliability are non-negotiable.

- Robotics and Automation: Urethane and rubber components like rollers, bushings, and grips help robotic arms, conveyors, and automated machinery operate efficiently and accurately under repetitive or high-stress conditions.

- Mining and Material Handling: Heavy-duty rollers, bushings, and vibration mounts withstand harsh environments, reducing wear and maintaining operational consistency in conveyors, crushers, and industrial machinery.

- Marine: Marine-grade seals, vibration dampeners, and surface protection components resist saltwater corrosion and extreme weather, ensuring reliable performance in ships, boats, and offshore equipment.

- Oil and Gas: Custom molded parts handle high-pressure, high-temperature, and chemically aggressive environments, providing durable solutions for valves, pumps, and heavy equipment.

- Industrial Manufacturing: From conveyor systems to precision machinery, quality molded rubber products protect surfaces, reduce friction, and maintain equipment efficiency across production lines.

By leveraging industry-specific materials and designs, custom molded rubber and urethane components help businesses optimize operations, reduce downtime, and improve overall system performance. Uniflex, Inc.’s in-house capabilities for design, machining, and manufacturing allow rapid prototyping and production runs that meet the exact needs of each industry.

Manufacturing Processes for Custom Molded Rubber Parts

Choosing the right manufacturing method for custom molded rubber parts is essential to achieving the desired performance, precision, and cost-effectiveness. The most common processes—compression molding, transfer molding, and injection molding—each offer unique advantages tailored to different production requirements and part complexities.

Compression Molding

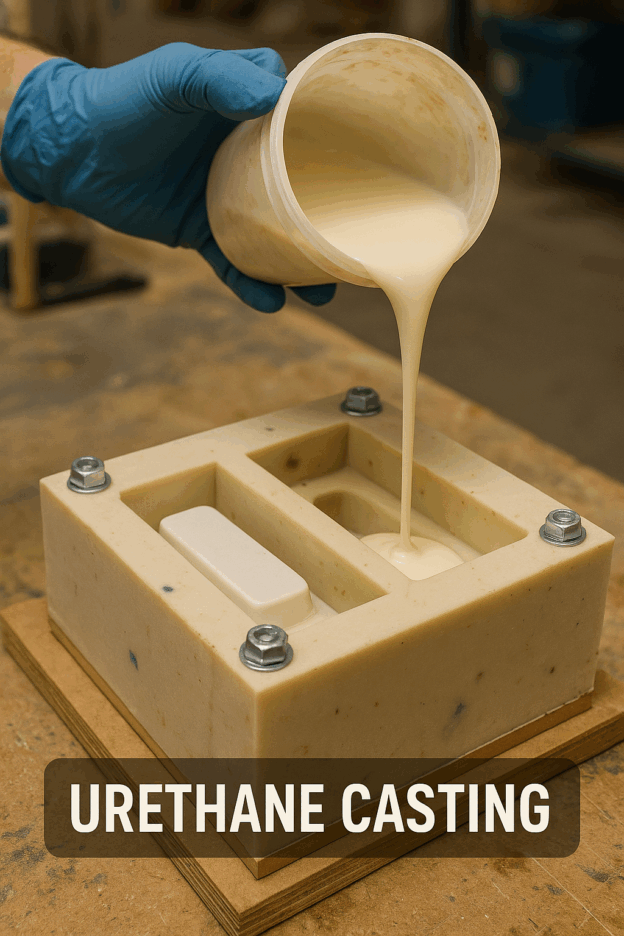

Compression molding involves placing a pre-measured amount of rubber material into a heated mold cavity, where it is shaped and vulcanized under pressure. This method is highly versatile, capable of producing complex shapes with minimal waste, and typically requires lower tooling costs compared to other molding processes.

Its repeatability and adaptability make compression molding suitable for both low- and high-volume production runs. Typical applications include automotive components, industrial gaskets, seals, and other parts where durability and precision are critical.

Transfer Molding

Transfer molding excels in producing parts with intricate details and tight dimensional tolerances. In this process, rubber material is placed in a chamber and then forced into a closed mold system, ensuring consistent quality and smooth surface finishes.

This method minimizes material waste and can accommodate both small and large components with complex geometries. Transfer molding is particularly suited for applications where precision, material control, and fine detail are essential, such as specialized industrial components, bushings, and precision seals.

Injection Molding

Injection molding is ideal for high-volume production of rubber parts with complex shapes and strict dimensional requirements. The process injects molten rubber into a mold cavity under pressure, producing parts with excellent consistency, repeatability, and surface quality.

Industries such as automotive, aerospace, robotics, and industrial manufacturing rely on injection molding for producing large quantities of durable, high-precision components. Its efficiency and scalability make it a cost-effective solution for businesses requiring consistent quality across extensive production runs.

Each manufacturing method offers distinct advantages, and selecting the right process depends on factors such as part complexity, production volume, material type, and cost considerations. With in-house capabilities for design, machining, and molding, Uniflex, Inc. provides tailored solutions that optimize both performance and efficiency for industrial applications.

👉Also Read: Advantages of Urethane Coated Bearings in High-Performance Applications

Choosing the Right Manufacturer for Custom Molded Rubber Parts in Michigan

Selecting a reliable manufacturer is critical to ensuring the quality, performance, and cost-effectiveness of your custom molded rubber components. Beyond pricing, value encompasses quality, service, and the manufacturer’s ability to meet your specific production needs. A strong partnership can streamline production, reduce lead times, and improve overall project outcomes.

When evaluating a manufacturer in Michigan, consider factors such as minimum order quantities, turnaround times, production capabilities, and experience with your industry. Collaboration with formulation experts and regular supplier audits further enhances product quality and ensures cost-effective solutions tailored to your application.

Material Selection for Custom Molded Rubber Parts

The right material is the foundation of effective custom rubber molding. Manufacturers offer a variety of elastomers—such as liquid silicone rubber, neoprene, EPDM, NBR, and other synthetic or natural rubbers—each with unique properties suited to specific applications. Material selection affects load-bearing capabilities, temperature resistance, chemical resistance, and durability.

Custom rubber formulations can be tailored to:

- Meet precise performance specifications

- Optimize cost efficiency without compromising quality

- Achieve specific colors, textures, or other physical properties

Selecting the correct material ensures components perform reliably under operational conditions while maximizing product lifespan and efficiency.

Quality Assurance in Custom Rubber Molding

Maintaining consistent quality is vital in custom rubber molding. A robust Quality Management System (QMS), along with industry certifications such as ISO, demonstrates a manufacturer’s commitment to high standards.

Key quality assurance practices include:

- Inspecting raw materials before production

- Conducting in-process testing for critical dimensions and properties

- Performing final product inspections to ensure conformity with specifications

Processes such as injection molding provide high repeatability and precision, making them ideal for applications where consistent quality is essential.

Custom Rubber Formulations and Compounds

Developing custom formulations involves a collaborative process:

- Defining performance requirements and application-specific needs

- Evaluating existing compounds for suitability

- Identifying cost-effective substitutions without sacrificing performance

These custom compounds allow manufacturers to produce rubber parts with tailored properties, including enhanced durability, chemical or temperature resistance, and specialized surface finishes. This flexibility is particularly important for industries such as automotive, mining, robotics, and material handling.

High Volume Production and Prototyping

Injection molding is particularly efficient for high-volume production, offering shorter cycle times compared to compression or transfer molding. Manufacturers that provide prototyping and pilot production services help clients transition smoothly from design to full-scale manufacturing.

Rapid prototyping accelerates product development, enabling prototypes to be created quickly for testing and evaluation, often in as little as one day. This approach minimizes development delays and ensures final parts meet design and functional requirements.

Customer Experience and Support

A manufacturer’s ability to provide clear communication, technical guidance, and responsive support is essential for a positive customer experience. Technical assistance can optimize design choices, material selection, and production processes, leading to better-performing components.

Reliable customer service ensures:

- Faster response times and reduced lead times

- Seamless post-production support

- Long-term partnership and supply chain efficiency

Choosing a manufacturer with strong customer support enhances satisfaction, reliability, and operational efficiency for all custom molded rubber and urethane projects.

Partner with Uniflex, Inc. in Michigan for Precision Custom Molded Rubber and Urethane Solutions

Custom molded rubber and urethane parts are critical for ensuring reliability, performance, and efficiency across industries such as automotive, aerospace, robotics, mining, marine, and industrial manufacturing. At Uniflex, Inc., we combine over four decades of expertise with in-house capabilities in design, machining, and manufacturing to deliver high-quality, cost-effective solutions for every application.

Whether you need low-volume prototypes, high-volume production runs, or specialty materials, our team works closely with you to create parts that meet your exact specifications, optimize performance, and extend equipment life. From precision seals and bushings to rollers, grips, vibration mounts, and custom-designed components, Uniflex, Inc. has the experience and technology to bring your project from concept to production efficiently.

Request a Quote Today

Partnering with Uniflex, Inc. means faster lead times, superior quality, and responsive customer support throughout the design and production process. Contact us today to discuss your custom molded rubber and urethane requirements and discover how our solutions can enhance the performance and reliability of your operations.

Frequently Asked Questions About Custom Molded Rubber Products

What are the primary differences between injection molding and compression molding?

Injection molding involves injecting heated rubber into a mold under high pressure, resulting in precise, complex parts suitable for high-volume production. Compression molding places pre-measured rubber into an open mold, applying heat and pressure to form simpler parts, often used for larger components or lower-volume runs.

How do I determine the appropriate rubber material for my application?

The choice of rubber material depends on factors such as temperature resistance, chemical exposure, flexibility, and durability requirements. Common materials include Nitrile (NBR), EPDM, Silicone, and Viton®. Consulting with a materials engineer or a reputable supplier can help identify the best fit for your specific needs.

What is the typical lead time for custom molded rubber parts?

Lead times vary based on the complexity of the design and tooling requirements. Prototype molds may take 2–4 weeks, while production molds can require 6–10 weeks. Once tooling is complete, part production lead times typically range from 3 to 4 weeks, depending on order quantity.

Can custom molded rubber parts achieve tight tolerances?

Yes, custom molded rubber parts can be manufactured to meet tight tolerances, including RMA A1 standards. However, due to the flexible nature of rubber, achieving ultra-tight tolerances may be more challenging compared to metals or rigid plastics.

What factors influence the cost of custom molded rubber parts?

Cost factors include material selection, mold complexity, part design, production volume, and any secondary operations required (e.g., bonding, machining). Understanding these elements can help balance cost with performance and quality requirements.