Urethane elastomers possess unique characteristics that set them apart in the world of materials. Their definition and key properties, such as excellent flexibility and durability, establish them as a sought-after choice. Custom molding plays a crucial role in the production of urethane elastomers, allowing for tailored solutions that meet specific application requirements. The blog’s focus centers around enhancing the durability and flexibility of urethane elastomers, highlighting their significance and potential in various industries.

Are you in need of high-quality custom-molded urethanes, elastomeric polyurethane, and rubber at competitive prices? Look no further than Uniflex, Inc.! With over four decades of expertise in the industry, we have established ourselves as a trusted supplier to a wide range of industries, including aerospace, automotive, robotics, military, oil, gas, mining, and marine. Visit our website or reach out to our knowledgeable team at 248-486-6000 to discuss your specific requirements and receive a personalized quote.

👉Also read: The Top 4 Industries That Benefit From Custom Polyurethane Products

Understanding Urethane Elastomers and Their Properties

Urethane elastomers stand out when compared to conventional elastomers and plastics due to their unique combination of properties. While conventional elastomers offer flexibility and plastics provide rigidity, urethane elastomers offer a balance of both. This versatility makes them suitable for a wide range of applications across various industries.

One of the key properties of urethane elastomers is their exceptional abrasion resistance. They can withstand wear and tear, making them ideal for applications exposed to harsh conditions, such as industrial machinery components or conveyor belts. Additionally, urethane elastomers exhibit high tear strength, ensuring their longevity even under heavy loads or frequent stretching.

Another significant advantage of urethane elastomers is their resistance to microbial attacks. This property makes them suitable for applications where hygiene and cleanliness are crucial, such as medical equipment or food processing machinery. The resistance to microbial growth helps maintain a sterile environment and prevents contamination.

The Chemistry Behind Urethane Elastomer

Urethane elastomers are formed through a process called urethane polymerization. This process involves the reaction between long-chain polyols and isocyanate compounds. The combination of these two components results in the formation of a cross-linked network, creating the elastomeric properties of urethane.

Varying the formulation of urethane elastomers can have a significant impact on their material properties. By adjusting the ratio of polyols and isocyanates, manufacturers can modify the hardness, flexibility, and other characteristics of the elastomers to meet specific application requirements. This customization allows for tailored solutions that address the unique needs of different industries.

In addition to their performance properties, the environmental friendliness of urethane elastomer is also a significant aspect. Many urethane elastomers are formulated to be free of hazardous substances and volatile organic compounds (VOCs), making them safer for both users and the environment. This aligns with the growing demand for sustainable materials and reinforces urethane elastomer as a responsible choice in various applications.

👉Also read: Find The Best Customized Urethane Products — Shop Uniflex

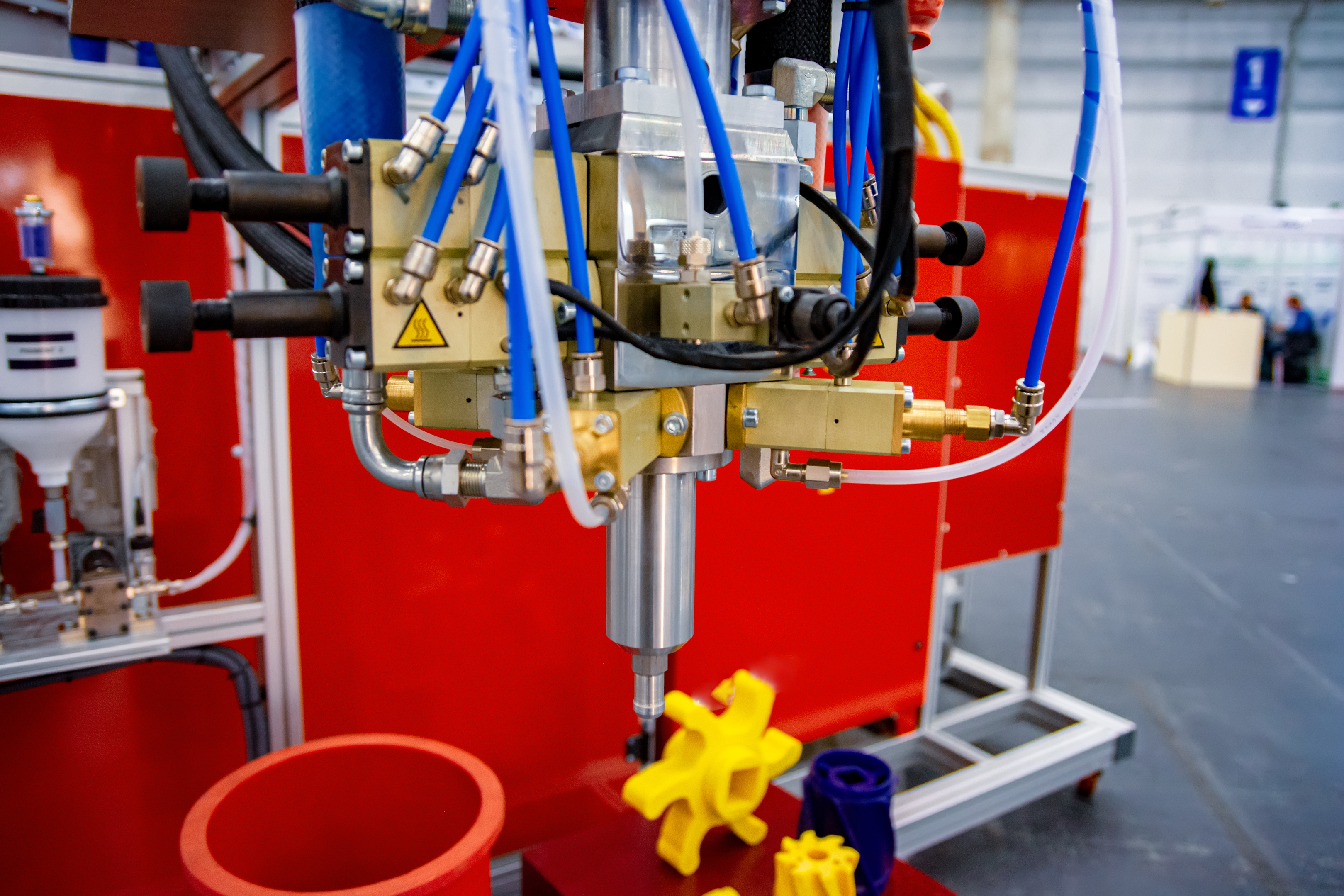

Custom Molded Urethane Elastomers: Manufacturing Process

The manufacturing process of custom-molded urethane elastomers involves carefully controlling the molding parameters to achieve the desired properties. Varying the hardness and elasticity of the elastomers is crucial for specific applications. By adjusting the formulation and curing process, manufacturers can create urethane elastomers with the ideal balance of hardness and flexibility, tailored to meet the unique requirements of each application. Additionally, the viscosity of the material plays a vital role in the molding process. Optimal viscosity ensures that the material flows evenly into the mold, allowing for the creation of precise and durable components.

Advantages of Custom Molded Urethane Elastomers

Custom-molded urethane elastomers offer a range of advantages over conventional elastomers. One of the key benefits is their enhanced durability and flexibility. These elastomers can withstand demanding conditions and maintain their performance over an extended period, making them ideal for applications where longevity is crucial. Additionally, custom molded urethane elastomers exhibit excellent flexibility, allowing them to adapt to different shapes and movements without compromising their integrity.

Another advantage is their high-pressure resistance, which makes them well-suited for use in demanding industrial settings. Urethane elastomers can withstand extreme pressures without deformation or failure, ensuring their reliability in critical applications. This high-pressure resistance opens up opportunities for their utilization in industries such as hydraulics, pneumatics, and heavy machinery.

The versatility of urethane elastomers is another significant advantage. By tailoring the formulations, manufacturers can create elastomers with specific properties to meet the unique requirements of various industries. This versatility enables their application in the automotive and aerospace industries for components like seals, gaskets, and suspension systems. They are also used in oil and gas applications for sealing systems and downhole tools. Additionally, urethane elastomers find use in industrial machinery and manufacturing components such as rollers, bushings, and wear-resistant parts.

Applications and Industries Using Urethane Elastomers

Urethane elastomers have found extensive use in a variety of industries due to their exceptional properties and versatility. In the automotive industry, they are utilized in applications ranging from engine mounts to weatherstripping, where their durability, flexibility, and resistance to oil and chemicals are highly valued. The aerospace industry also relies on urethane elastomers for components like seals and vibration dampeners, benefiting from their ability to withstand harsh environmental conditions and extreme temperatures.

In the oil and gas industry, urethane elastomers find application in seals, packers, and other downhole tools. Their resistance to chemicals, oils, and high pressures makes them suitable for challenging environments. Additionally, urethane elastomers play a significant role in industrial machinery and manufacturing components, providing excellent wear resistance and durability in applications such as rollers, couplings, and bushings.

These examples demonstrate the wide range of industries and applications that benefit from the unique properties of urethane elastomers. Their ability to enhance performance and reliability in demanding conditions solidifies their position as a preferred choice for numerous industries seeking durable and flexible solutions.

Ensuring Safety and Environmental Benefits

Custom-molded urethane elastomers offer safety and environmental benefits. They have low levels of volatile organic compounds (VOCs), reducing potential harm to users and the environment. Furthermore, their resistance properties help minimize the risk of oil and chemical leaks, promoting a safer working environment. Exploring the environmentally friendly aspects of urethane elastomers further highlights their sustainability advantages, making them a responsible choice for various applications.

Future Trends and Advancements in Urethane Elastomers

The future of urethane elastomers looks promising, with ongoing innovations in custom molding techniques and equipment. Advancements in these areas are expected to further improve the overall performance and durability of urethane elastomers.

Additionally, exploring the potential of urethane elastomers in new industries opens up opportunities for their application in previously untapped markets. These advancements and trends will contribute to the continued growth and development of urethane elastomers as a versatile and high-performing material.

👉Also read: How Urethane Products Are Revolutionizing The Robotics Industry

Uniflex, Inc.: Your Trusted Partner for Custom-Molded Urethane Elastomers

At Uniflex, Inc., we understand the importance of reliability, performance, and cost-effectiveness in your projects. Our team of skilled professionals excels in the art of custom molding, utilizing cutting-edge techniques and equipment to create urethane elastomers that exhibit unmatched durability and flexibility. By working closely with you, we ensure that every aspect of the molding process is precisely tailored to your requirements, resulting in high-quality, custom-molded parts that exceed your expectations.

As your trusted partner, we take pride in offering comprehensive solutions under one roof. From design and machining to manufacturing, we handle every step of the process with meticulous attention to detail. This integrated approach not only ensures superior quality control but also allows us to streamline production, reducing lead times and keeping costs competitive.

To explore how our custom-molded urethane elastomers can meet your specific requirements, we invite you to visit our website or reach out to our knowledgeable team at 248-486-6000. We are ready to discuss and address your needs for enhanced durability and flexibility in your applications.