When it comes to selecting the right material for your industrial roller applications, you probably have a lot of questions. This is especially about the polyurethane vs. rubber rollers debate. If your current equipment originally came with rubber rollers, would it be acceptable for you to use polyurethane rollers instead of the rubber ones? Let’s take a closer look at both so that you can make a well-informed choice.

Polyurethane vs. Rubber Rollers: Is There Any Difference?

Before we talk about the differences, let’s consider the commonalities between the polyurethane vs. rubber rollers.

- Both are elastomers, i.e., both have elastic properties.

- Moreover, both are excellent in terms of adhering to metal cores.

- Both are resistant to acid, whether it is concentrated or diluted.

- Also, both offer poor resistance to lacquer solvents.

- And, both are machinable when you need a pattern on the outer diameter of a roller to perform a particular task.

So clearly, there are a lot of similarities between polyurethane vs. rubber rollers. However, there are quite a few differences as well:

Chemical Composition

Polyurethane can be formulated in hundreds of different ways to give you the required properties your application needs. It is possible to add fillers to the sap-derived rubber to change its properties but there’s a limit to how much you can customize it.

Wet Environments

If you need a material that will be exposed or submerged into wet environments for extended periods, polyurethane will outperform rubber every time. Polyurethane doesn’t rot. Rubber, on the other hand, will rot.

Durometer (Hardness)

While processing of rubber in 30-Shore A to 90-Shore A is possible, polyurethane has a much wider range from 10-Shore “OO” to 70-Shore “D”.

Unwanted Pigmentation

Rubber manufacturers add carbon to rubber, which can leave black marks on products it comes in contact with. Polyurethane, on the other hand, does not leave any marks or color on any product even when pigment is added to the polyurethane.

Abrasion Resistance

When a combination of high friction and dynamic loads happens, rollers can experience a great deal of abrasion. Polyurethane again surpasses rubber since polyurethane is extremely resistant to abrasion, corrosion, and high pressures.

Final Decision

The above analysis doesn’t cover all the differences between polyurethane vs. rubber rollers. But, they are significant enough to affect your decision. Just remember, these differences can add up in manpower and downtime if you’re not using the best material for your specific application.

Reduce Your Cost & Lead Time with Polyurethane Rollers

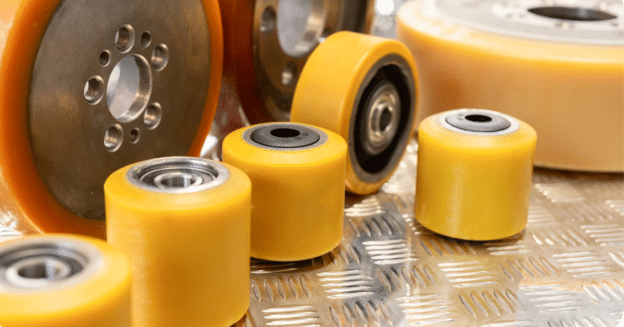

Due to the considerable chemical capabilities of polyurethane and the range of hardness/durometers, this material can keep your machinery up and running to a degree that rubber simply cannot. Polyurethane may not be suitable for every roller application, but if you’re looking for the highest quality urethane that will meet your precise specifications, it’s worth considering.

Contact Uniflex Inc. to Learn More About Polyurethane

If you want to know more about polyurethane vs. rubber rollers and whether the former will be the right choice for you, we will be happy to answer all your questions and concerns. We have been making custom molded polyurethane rollers for over 40 years and can advise you on the best option. You can reach us at 248-486-6000 or complete this online contact form to discuss your requirements with us.