Urethane sheets are versatile products that can be used in a variety of industrial applications. They are made from polyurethane, which is a synthetic polymer known for its durability and strength. It is far from a traditional material. Open cast urethane sheets can be used in the manufacturing, construction, and automotive industries, plus others that have lower tooling costs.

A Brief History of Urethane

Back in 1937, a German chemist named Friedrich Bayer first created the original blueprint for polyurethane, also known as PU or Perlon U. The year 1940 was marked as the year that saw the successful development of the first polyurethane elastomers. Their physical properties are comparable to those of rubber.

This new kind of material immediately became a cheaper option than normal rubber during World War II, which was an expensive commodity due to its scarcity. One polyurethane use was as a protective coat on the outside of airplanes used in the battle. Later on, researchers came to the realization that polyurethane could be merged with nylon to create a material that was not only lightweight, but also had elastic memory.

This elastic memory was accomplished by synthesizing the material into fine threads. The first commercial manufacture of polyurethane foam was in the United States in 1953. The foam was stiff and its primary use was insulation. This lasted only until 1956, when more flexible and less expensive foams entered the market. When moldable polyurethane was invented in the late 1950s, it was already being utilized as a binder.

The malleability of the material allowed for the development of new uses, such as the production of versatile pillows. The development of polyurethane has now progressed to the point where it can manufacture several useful types of materials, such as coating materials made of polyurethane, stretchy strands, and injection molded parts. Polyurethane components can be found in any number of things.

The Other Uses of Urethane Besides Plastics

Adhesives, coatings, and sealants made from liquid urethane are the most popular applications for this material. Urethane adhesives are used in the automotive and construction industries because they offer high bond strength, flexibility, and weather resistance. Coatings and sealants made from urethane protect surfaces from abrasion, chemicals, and corrosion.

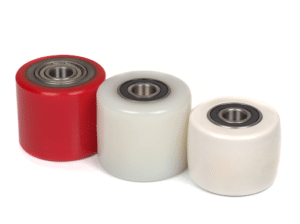

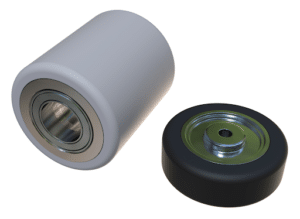

Urethane is also used as an elastomer in tires, rollers, and other impact-absorbing applications. This material is well-suited for these uses because it has high abrasion resistance and can withstand compression without deforming. The product is also used to make gaskets and o-rings because of its excellent resistance to chemicals and temperature extremes.

The Basics of Urethane Sheets

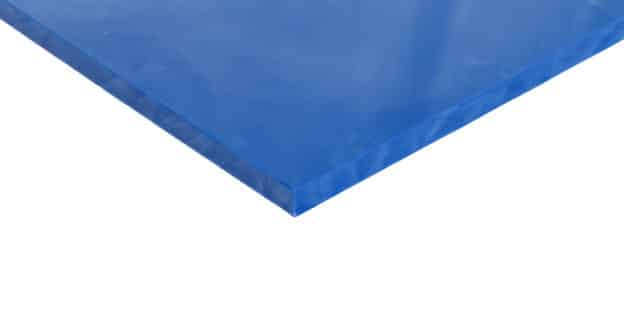

When it comes to understanding industrial polyurethane, it is important to first understand the basics of standard cast urethane sheets. Urethane is a polymer that can be either rigid or flexible and is known for its high resistance to wear and tear. This makes it an ideal material for a wide variety of applications, in industrial settings and beyond. By understanding the basics of urethane sheeting, you will be able to make better-informed decisions about their use in your own projects.

What Puts the Poly Into Polyurethane?

Urethane is flexible and malleable, making it perfect for item sizing and manufacturing. It is a polymer, which is a long chain of organic units that are connected to each other through chemical compounds and can be derived from both natural and synthetic sources. It is the material’s molecular structure, which consists of long chains of alternating organic units, that gives it physical properties like hardness and resilience.

The real strength of urethane, however, lies in its versatility. It can be molded, cast, or extruded into a variety of shapes and sizes. And, because of its tear resistance, it’s often used in material handling applications.

When it comes to plastics, polyurethane sheets are in a category of their own. That’s because this versatile material can be either rigid or soft, depending on how it’s made. Polyurethane is created by combining a polyol and isocyanate, and the ratio of these two ingredients combined with curing agents determines the hardness of the final product.

Polyurethane sheets are often used in applications where physical strength is a must. This kind of material is flexible and does not permanently deform, so it works well for things that need to bend or give, like chute liners or pads. For material handling, where durability is key and a high degree of longevity is required, polyurethane reigns supreme.

Durometer Ratings, Thickness, and Common Measurements

Urethane sheeting comes in a wide variety of standard durometer ratings, thickness, and common measurements. When choosing a urethane sheet for your application, it is important to consider the stocked inventory dimension tolerances. This can help to ensure you are getting the right product for the job that will also best suit your needs.

Durometer Rating

Polyurethane formulations cover a very broad hardness range, from very soft to very hard. The hardness range of a urethane sheet is measured from 40 Shore A to 75 Shore D. On the low end of the scale, Shore 00 urethanes have a gummy feel and are used in applications where flexibility and lower impact shock absorption are key. On the high end of the scale, shore D urethanes are much harder and are used in applications where abrasion resistance and durability are key.

Thickness

Cast urethane sheets are available in a wide variety of thicknesses, from 0.125″ to over 6″. These are measured in either English or metric units. When choosing the right durometer and thickness for your application, polyurethane flat sheet stock is available in thickness standard sizes. It is important to consider the weight of the object that will be resting on the urethane sheet as well as the desired level of thickness. This can help you determine whether you need a thin, flexible sheet, or a thick, rigid one.

Common Measurements of Urethane

Urethane sheets are conveniently available in standard stock size as well as custom sizes. Standard stock sizes are 48″ x 138″, 48″ x 120″, 48″ x 96″, and 48″ x 48″. These dimensions allow for easy handling and transportation of the sheets, which is ideal for many applications. Custom sizes are also available for those who need a specific size or shape for their project. This is to fit your specific application needs so you don’t have to worry about waste and can get the most out of your urethane sheet.

Urethane Sheets and Pigmentation

Standard cast urethane sheets can be made in a wide selection of custom colors to achieve the right look for your industrial application. In addition, urethane can be formulated to resist UV exposure, meaning that your custom colors will not fade over time. Urethane is also well-suited for applications requiring sharp edges. When it comes to industrial applications, urethane sheets offer a lot of advantages. With the ability to customize color and formulate for different purposes, urethane can be adapted to fit many needs.

Common Industrial Applications

As mentioned before, urethane sheets are often used in common industrial applications. These applications typically require a high degree of versatility, durability, and abrasion resistance. Whatever the application, urethane can be formulated to meet specific needs. It can withstand both high and low temperatures, making it ideal for a wide range of projects. Urethane also has excellent chemical resistance, which makes it a good choice for many industrial applications that involve harsh chemicals.

Liners & Covers

A good-quality urethane sheet will protect the surface to which it is applied. This is because urethane has high tear and impact resistance. It can resist abrasion, both from objects and from chemicals. Urethane sheets can be used to protect many different kinds of surfaces, including:

Metal

Urethane can be used to line and replace metal surfaces to protect them from wear and tear. It is much more durable than traditional plastics, and it will not tear or wear out as fast. When applied to metal, urethane can provide a long lasting buffer between media and the metal surface. This allows economical replacement and longevity for equipment.

Noise Abatement

It is often that a lot of noise is generated in industrial settings. From large factories to the mining industry, there always seems to be some form of metal on metal contact. This creates a lot of noise that is often distracting to employees. Urethane sheets can be used to provide a shock absorption pad between these metal surfaces which significantly reduces noise and wear.

Abrasive Material Handling

Urethane pads can be used to line surfaces that come into contact with abrasive media such as rocks, sand, coal, ore, and salt. We often see applications for sheet in the mining industry where large volumes of abrasive substances are processed through expensive equipment that needs protection. Another common application is with chute and hopper liners in the agriculture industry. Here, pu sheets line metal grain chutes and hoppers to protect against degradation.

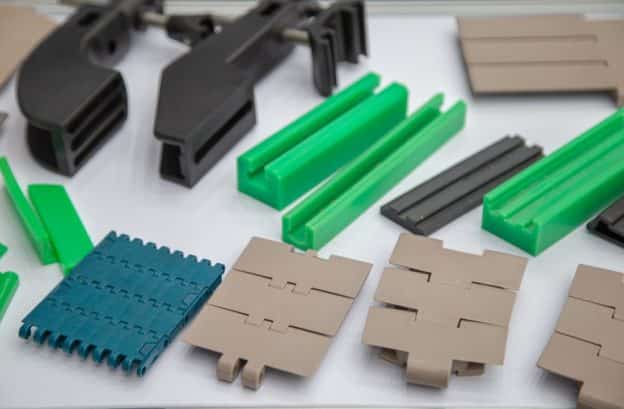

Cast Urethane Products

Cast polyurethane products are created using a mixture of a prepolymer and a curing agent. Different prepolymers and different curatives can be combined in custom ratios that allow endless versatility. Because of this, polyurethanes can be manufactured in a vast hardness range from 10 Shore A to 75 Shore D. Additionally, a multitude of physical properties can be created through resin and curative combinations. This can include tailoring tear strength, chemical resistance, rebound, and compression set to specific jobs.

Depending on the project, cast urethanes can be used to create a plethora of products such as rollers, bumpers, wheels, bushings, etc. Though, one the most common uses is in stock shapes.

Some common stock cast urethane products include:

Sheet

Polyurethane sheet is most often used as a liner to protect surfaces from wear. It is extensively used in the metal forming industry, mining industry, and automotive industry. It is very versatile and can be ordered in custom sizes and thicknesses. This allows cost savings and easy emplacement.

rod

Rod made from polyurethane is an excellent replacement for traditional hard plastics like UHMW, HDPE, Nylon, and Delrin. Unlike these hard plastics, urethane rod is non-marring and will not deform when impacted. This is due to its elastics memory. Urethane rod can be manufactured in any length, diameter, and hardness.

tube

Urethane tube can be made in standard or customized ODs and IDs. Lengths are generally 12″ to 48″. Common applications include springs, roller covers, protective sleeves, and liners. Cast urethane tubes differ from extruded tube as they use a thermoset urethane versus a thermoplastic urethane. Thermoset urethanes have much better physical properties.

bar

Cast urethane bar stock is used as a machinable plastic for milling or turning urethane parts from stock. The advantage to polyurethane bar stock is that it outperforms traditional materials like UHMW. Furthermore, bar stock can be used in other applications such as bumper pads, squeegees, and belt scrapers.

custom sheet, bar, & rod

All cast urethane stock such as sheet, rods, tubes, and bars can be custom manufactured. Because of urethanes liquid starting state, it allows for endless versatility. Any durometer, size, shape, and color can be manufactured. Custom tubes, elbows, rods, blocks, and sheet are very common in the manufacture of polyurethane products. Orders can be filled fast and efficiently with little or no tooling costs.

Common Products that Use Urethane Sheets

Urethane is such a versatile material so there are many items that industry uses on a daily basis that are made with this polymer. Whether in the form of elastomer, foam, or castable liquid, urethane can be found in many places.

While most people don’t think about it, urethane is actually a vital material in many different industries and products. By understanding a little more about this material, you can begin to see just how important it is for your company.

These are a few examples of products that you have probably come into contact with something that contains urethane:

bench covers

Urethane sheet is often used as a bench top cover to prevent surface damage. Not only does it protect the table surface from marring, but it also protects the components on the table. Generally, assembly operations will use urethane pads to protect the components they are assembling on work tables.

liners

One of the most common uses for polyurethane sheets is as liners. It is often seen in the agriculture industry as grain chute liners and hopper liners. You will also see urethane sheets in the mining industry being used as equipment liners and blast pads (among others).

metal forming pads

Metal forming pads require a great deal of tensile strength to withstand repeated, multi-ton impact. Polyurethane pads are excellent for this application and provide a long-lasting alternative to rubber.

mining industry Pads

Urethane sheeting is a staple in the mining industry. It is use to protect metal machinery from abrasive media such as gravel, sand, ore, and salts. In general its use is in aggregate handling where it provides a cost effective buffer for wear.

Conclusion

As you now know, urethane flat sheet stock offers a variety of benefits for industrial applications. By being abrasion resistant, plus by having oil resistance, wear resistance, chemical resistance, and insulation properties, it be used in so many applications that will improve the efficiency and productivity of your business.

Not only can you guarantee the quality of your finished product, but you can also save time and money in the long run. By considering all the urethane sheets applications, it’s easy to see why they’re becoming increasingly popular in the industrial sector. If you’re looking for a reliable and cost-effective provider of urethane sheets, then be sure to reach out to Uniflex.

We are experts in custom-molded urethane and cast precision rubber sheets. We can design, create, and manufacture all under one roof, which allows us to keep pricing low and lead times short. Since 1979, we have specialized in rubber combined custom molded urethane, and we have been a reliable supplier to the aviation, automobile, electronics, military, oil, gas, mining, and marine sectors. We strive for client satisfaction and supply high-quality, low-cost custom-molded components on which industries all over the world have come to depend. Request a quote today to see how we can help you with your urethane sheets or cast polyurethane sheets needs. Contact us now, and let’s create something together.