Over the last 50 years, nearly everything about food has undergone a significant change – how we cook it, buy it, eat it, raise it, grow it, and package it. The modern food and beverage industry is much more focused on sanitation, hygiene and safety in their production, packaging, and distribution practices to eliminate the risk of contamination.

In this post, we will take a look at some of the vital facts you need to know about food-grade urethane pertaining to the food processing industry today.

Transition From Cheap Plastic To Food Grade Urethane

As seals and gaskets are two of the most significant components in almost all food processing systems and equipment, they also have undergone major modifications. Instead of using the seals and gaskets made from standard plastic materials – which was the norm up until a couple of decades ago – the food processing manufacturers are now making use of food-grade urethane.

This change occurred after the industry leaders realized that most of the sanitary issues and food contamination are caused by gasket/sealing units made from subpar quality materials. While there are many options when it comes to gasket materials, such as Viton, silicone, and EPDM, food-grade urethane or polyurethane is the only FDA-approved material due to several reasons:

- It has high abrasion and impact resistance and will not crack, tear, or break easily.

- It has an extremely high load-bearing capacity.

- It has exceptional tear-resistance and high-tensile properties.

- It is capable of demonstrating high mechanical strength even at exceedingly low temperatures.

- It is resistant to harsh environmental factors involving acids, oils, solvents, and heat.

- It possesses a wide molecular structural variability.

- It lasts much longer than other gasket/sealing materials such as plastic, silicone, rubber, fiberglass, felt, and neoprene.

- It prevents the growth of mold, mildew, and fungi even when it is in constant contact with edible or liquid items.

- It is resistant to aromatic hydrocarbons, and vegetable and mineral oils.

- It offers superior performance at temperatures ranging from -30°F to 220°F

Choose FDA-Compliant, Food-Grade Urethane For Your Food Processing Applications

Under section #177.21000, subpart F, food grade urethane is acceptable for repeated contact with edible items. If you’re looking for non-allergenic, non-marking, and non-toxic material for your food-related operations, FDA-approved polyurethane is the perfect choice.

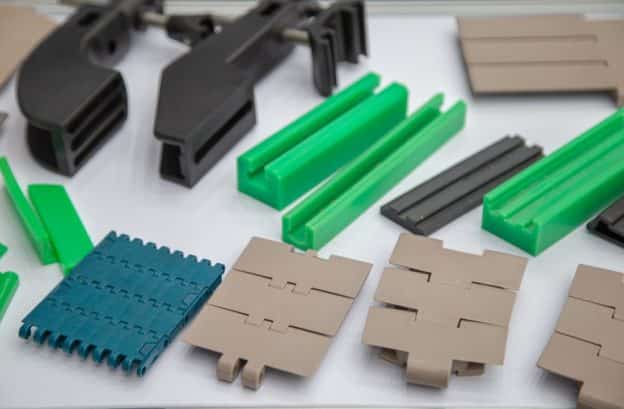

In addition to gaskets and seals, applications include:

- Transfer systems and hoppers

- Feet and bumpers

- Wheels and bumpers

- Inspection tables

- Chutes and chute liners

- Conveyor systems

- Sprockets

- Belt scrapers

- Custom molded parts

Contact Us For Quality, FDA-Approved, Food Grade Urethane & Polymers

The Food & Drug Administration has set a limited list of approved polymers that are considered safe to be used in the food processing industry and are allowed to be used for parts that come in contact with food items.

Our food-grade urethane components are certified by the FDA for both dry and wet applications. This means that regardless of what type of environment you are processing food in, Uniflex Inc. polyurethane products are the solution you need.

If you have any questions, you can call us at 248-956-6765 or request a quote online.