When it comes to creating durable, versatile, and cost-effective parts, urethane casting has become a go-to manufacturing process across industries ranging from automotive and robotics to mining and marine. But what exactly is urethane casting, and why do so many companies rely on it for critical components?

This comprehensive guide explores the processes, materials, and practical applications that make cast urethane one of the most dependable solutions in modern manufacturing. Whether you’re sourcing custom molded urethane rollers, bushings, or precision parts for specialized equipment, understanding how urethane casting works will help you choose the right materials and suppliers for your project.

At Uniflex, Inc., we’ve been perfecting the art of custom-molded urethane and rubber since 1979. With in-house design, machining, and manufacturing all under one roof, we deliver high-quality parts with shorter lead times and competitive pricing. From oil and gas companies needing heavy-duty seals and components, to automotive manufacturers sourcing durable bushings and rollers, to mining operations that rely on abrasion-resistant urethane parts, we provide solutions tailored to keep industries running efficiently.

Ready to get started? Contact us today at 248-486-6000 or request a fast, free quote to see how Uniflex, Inc. can deliver the right urethane solution for your business—whether you’re in oil and gas, automotive, mining, robotics, or beyond.

👉Also Read: The Engineer’s Guide to Exploring High-Performance Castable Urethane Elastomers

What Is Urethane Casting?

Urethane casting is a manufacturing process that produces high-quality, custom parts with exceptional precision, durability, and flexibility. Unlike traditional manufacturing methods that rely on expensive metal tooling, urethane casting employs soft molds or master patterns, typically made from silicone, making it significantly more affordable and quicker to set up.

Key advantages include:

- Cost-Effective Tooling: Silicone molds cost a fraction of metal molds, reducing initial investment

- Rapid Production: Liquid polyurethane cures at room temperature, enabling efficient production timelines

- Design Flexibility: Accommodates complex geometries and intricate details that closely mimic injection-molded parts

- Material Versatility: Supports a wide range of urethane formulations to meet specific performance requirements

- Low-to-Medium Volume Efficiency: Ideal for prototyping and production runs from 10 to 10,000+ parts

This manufacturing method is particularly beneficial for creating durable, custom components tailored to meet specific industrial needs without the high costs and long lead times associated with metal tooling.

Urethane Casting Processes

The urethane casting process encompasses three primary methods, each with unique operational characteristics suited for different applications and production requirements.

Compression Molding

Compression molding involves placing pre-measured urethane material into an open mold tool, then applying heat and pressure to form the final product. This method excels at producing urethane cast parts with complex geometries that might be challenging to achieve through other techniques.

Advantages:

- Lower tooling costs compared to injection molding

- Excellent for intricate shapes and large parts

- Minimal material waste

- Ideal for medium-durometer parts (40A-70D Shore)

Design Considerations:

- Use dowel pins to maintain through-hole integrity during mold-making

- Simplify geometries where possible to reduce mold complexity and costs

- Consider draft angles of 2-5° for easier part release

- Maintain uniform wall thickness to ensure even curing

Best Applications: Automotive bumpers, industrial rollers, large bushings, wear pads, and custom gaskets.

Transfer Molding

Transfer molding uses pressure to force heated urethane material from a transfer pot through runners into an enclosed mold cavity. This process provides superior control over material flow compared to compression molding.

Advantages:

- Excellent for parts with thicker cross-sections (up to 2″)

- Better dimensional control than compression molding

- Reduces flash and post-processing requirements

- Ideal for multi-cavity molds

- Produces parts with tighter tolerances (±0.005″)

Design Considerations:

- Account for material flow patterns to avoid weak spots

- Design runner systems to minimize waste

- Consider gate locations to prevent air entrapment

- Optimize for parts requiring inserts or metal components

Best Applications: Electrical connectors, valve seats, seals with complex profiles, automotive suspension components, and parts requiring embedded inserts.

Injection Molding

Injection molding represents the most automated urethane casting process, capable of producing millions of parts annually with exceptional consistency and tight tolerances.

Advantages:

- Highest production speeds (cycle times of 30 seconds to 5 minutes)

- Excellent repeatability and dimensional accuracy (±0.003″)

- Minimal post-processing required

- Lowest per-unit cost at high volumes (10,000+ parts)

- Superior surface finish quality

Design Considerations:

- Design for manufacturability with consistent wall thickness (0.060″-0.250″)

- Include proper venting to prevent air traps and burn marks

- Optimize gate locations for balanced filling

- Consider ejection methods early in design phase

Best Applications: High-volume automotive components, consumer product parts and any application requiring thousands of identical parts with tight tolerances.

👉Also Read: Molded Urethane: 10 Facts and 5 Myths Every Manufacturer Should Know

Key Materials Used in Urethane Casting

Material selection is critical to the performance, durability, and cost-effectiveness of your final product. Urethane materials offer a remarkable range of properties, measured on the Shore durometer scale, which determines hardness, flexibility, and application suitability.

Understanding Shore Hardness

- Shore A Scale: Measures softer, more flexible urethanes (20A-100A)

- Shore D Scale: Measures harder, more rigid urethanes (40D-85D)

- Reference Points: 20A feels like a rubber band, 60A like a tire tread, 90A like a skateboard wheel, 60D like a hard hat

Rigid Urethanes

Rigid urethanes typically range from 65 Shore D and above, providing exceptional structural strength and wear resistance.

Properties:

- High load-bearing capacity

- Excellent dimensional stability

- Superior abrasion resistance

- Low compression set

- Can achieve tight tolerances

Common Applications:

- Industrial machinery gears and couplings

- Structural automotive components

- Heavy-duty wheels and casters

- Mining equipment wear parts

- High-impact protective components

Flexible Urethanes

Flexible urethanes range from 20A to 60A Shore, offering enhanced elasticity, tear resistance, and impact absorption.

Properties:

- Superior elongation (up to 600%)

- Excellent tear and puncture resistance

- Good vibration damping

- Temperature resistance (-40°F to 200°F)

- Chemical resistance to oils, greases, and mild solvents

Common Applications:

- Automotive bushings and mounts

- Shock absorbers and vibration isolators

- Flexible couplings and bellows

- Seals and gaskets

- Consumer goods requiring soft-touch surfaces

Specialty Urethanes

Specialty urethane formulations address specific environmental challenges and regulatory requirements beyond standard materials.

Available Formulations:

- UV-Resistant Urethanes: Include UV stabilizers to prevent degradation and discoloration from sunlight exposure—critical for outdoor applications in agriculture, marine, and architectural uses.

- Flame-Retardant Urethanes: Meet UL94 standards for applications in electronics, aerospace, and building materials where fire safety is paramount.

- High-Temperature Urethanes: Maintain properties up to 300°F for applications near engines, industrial ovens, or heat-generating equipment.

- FDA-Compliant Urethanes: Approved for direct food contact in processing equipment, conveyor components, and packaging machinery.

- Conductive/Anti-Static Urethanes: Prevent static buildup in electronics manufacturing and explosive environments.

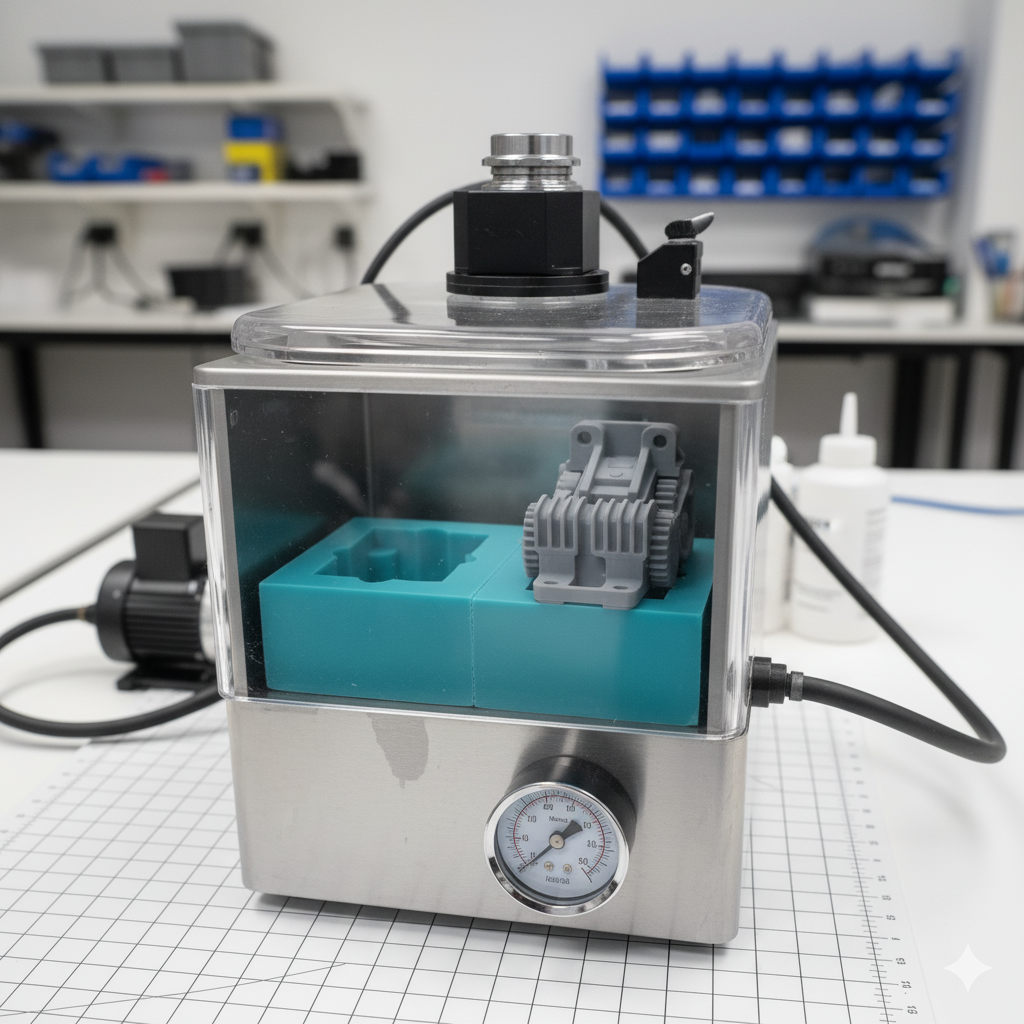

Critical Process Parameters in Urethane Casting

In urethane casting, process control is everything. The final performance and durability of a part depend heavily on how well critical parameters are managed during production.

Temperature plays a vital role during curing, as even slight variations can significantly affect the mechanical properties and long-term reliability of the finished part. Pressure control is equally important; maintaining the right pressure throughout the curing phase reduces the risk of internal voids and improves the overall surface quality of the cast component. Finally, curing time directly impacts part strength and finish—too short, and the material may not fully develop its properties; too long, and inconsistencies can arise that compromise performance.

By carefully managing temperature, pressure, and curing time, manufacturers can ensure consistent quality and meet exact project specifications. Optimizing these parameters not only results in parts with superior strength and precision but also helps minimize waste and improve cost efficiency.

Practical Applications of Urethane Casting

Urethane casting serves diverse industries, each leveraging the unique properties of polyurethane to solve specific engineering challenges.

Automotive Industry

The automotive sector relies heavily on custom urethane components for their durability, vibration damping, and cost-effectiveness.

Common Applications:

- Suspension bushings and control arm mounts

- Engine and transmission mounts

- Bump stops and jounce bumpers

- Rack and pinion bushings

- Steering column components

- Interior trim pieces and soft-touch surfaces

- Prototype parts for new vehicle development

Aerospace and Marine

These demanding environments require materials that deliver exceptional performance under extreme conditions.

Aerospace Applications:

- Vibration isolators for avionics equipment

- Lightweight structural components

- Cable grommets and protective boots

- Interior panels and seating components

- Environmental seals for doors and hatches

Marine Applications:

- Corrosion-resistant hull components

- Propeller shaft bearings and seals

- Deck fittings and hardware

- Vibration dampeners for engine mounts

- Buoys and underwater equipment housings

Robotics and Automation

Precision robotics demands components that combine accuracy with durability.

Common Applications:

- Gripper pads and end-effector components

- Cable management systems and protective boots

- Precision wheels and drive rollers

- Shock absorption bumpers

- Custom gaskets for environmental sealing

- Pneumatic seals and actuator components

Mining and Heavy Industry

Mining equipment operates in the harshest conditions, requiring components that withstand extreme abrasion, impact, and chemical exposure.

Common Applications:

- Screen media and wear liners

- Conveyor rollers and pulleys

- Chute linings and impact bars

- Slurry pump components

- Cyclone cone liners

- Pipe couplings and seals

Additional Industries

Oil & Gas: High-pressure seals, drill bit components, pipeline wear pads, and corrosion-resistant fittings.

Material Handling: Conveyor rollers, impact wheels, chute liners, and wear strips that extend equipment life.

Agricultural Equipment: Seed planter components, harvester parts, and chemical-resistant seals for spray systems.

Choosing the Right Manufacturer for Urethane Casting

Selecting the right manufacturing partner is as critical as choosing the right material. The ideal manufacturer becomes a collaborative partner in your product development process.

Essential Manufacturer Capabilities

1. In-House Design and Engineering Support

- Experienced engineers who can optimize your design for manufacturability

- CAD capabilities for rapid prototyping and design modifications

- Ability to perform finite element analysis (FEA) for stress testing

- Material selection expertise based on application requirements

2. Complete Manufacturing Integration

- In-house mold-making capabilities to control quality and reduce lead times

- Multiple casting processes under one roof (compression, transfer, injection)

- CNC machining for post-casting operations

- Assembly services if your project requires multi-component solutions

3. Quality Assurance Systems

- ISO 9001 certification or equivalent quality management systems

- In-house testing capabilities (Shore hardness, tensile strength, tear resistance)

- First-article inspection processes

- Documented process controls and traceability

4. Material Expertise

- Access to multiple urethane suppliers and formulations

- Ability to develop custom formulations for unique requirements

- Knowledge of specialty urethanes (UV-resistant, flame-retardant, medical-grade)

- Material testing and validation capabilities

Red Flags to Avoid

- Manufacturers who outsource mold making (add cost, lead time, and quality control issues)

- Limited material options or exclusive relationships with single suppliers

- No engineering support for design optimization

- Long lead times (4+ weeks for prototypes suggest inefficient processes)

- Unwillingness to provide material certifications or test data

- No clear quality control processes or documentation

Questions to Ask Potential Manufacturers

- Can you create molds in-house, and what’s your typical lead time?

- What urethane casting processes do you offer, and which would you recommend for my application?

- Do you have experience in my industry with similar applications?

- What material testing capabilities do you have in-house?

- Can you provide design for manufacturability (DFM) feedback?

- What are your minimum order quantities and volume pricing structures?

- How do you handle quality control, and what documentation do you provide?

- What is your typical production lead time for prototypes versus production runs?

The Value of Early Supplier Engagement

Engaging with your urethane casting supplier during the design phase—not after designs are finalized—can reveal significant opportunities:

- Cost Savings: Design modifications that reduce mold complexity can save 20-40% on tooling costs

- Performance Improvements: Material experts can suggest formulations that exceed your initial specifications

- Faster Time-to-Market: Identifying manufacturing challenges early prevents costly redesigns

- Quality Enhancement: DFM feedback ensures parts are optimized for the casting process

Factors Affecting Production Costs in Urethane Casting

Urethane casting is often chosen for low to medium production volumes because it offers a cost-effective alternative to metal molding methods. However, several factors influence production costs, and understanding them is essential for accurate budgeting and efficient manufacturing.

Production Volume

The quantity of parts being produced directly impacts the cost per unit. Higher production volumes typically reduce costs due to economies of scale, while very low-volume runs may have higher per-unit prices because fixed costs, like mold creation, are spread over fewer parts.

Design Complexity

Intricate designs or parts with tight tolerances can increase costs. Complex geometries often require detailed molds and extended production times, which drive up labor, material, and mold fabrication expenses.

Mold Creation

Mold fabrication is one of the largest expenses in urethane casting. Costs vary depending on mold material and complexity. For example, silicone molds are more affordable and flexible for small production runs, whereas metal molds are more durable but significantly more expensive. The choice of mold material should align with the intended production volume and part requirements.

Material Selection

Specialty urethanes, high-performance elastomers, or FDA-compliant materials can increase costs. Material choice affects not only performance but also overall project pricing, particularly when using proprietary or high-grade compounds.

Pricing Models and Discounts

Understanding pricing structures—such as per-unit pricing, volume-based discounts, and tiered production rates—is crucial for planning and cost management. Many manufacturers offer reduced rates for repeat orders or larger batch sizes.

By considering these factors—production volume, design complexity, mold type, material choice, and pricing models—manufacturers can optimize costs while producing high-quality urethane parts that meet specific performance requirements. Proper planning and process insight help ensure projects stay on budget without compromising part quality or reliability.

👉Also Read: Is Polyurethane Toxic to Skin? What You Need to Know

Why Choose Uniflex, Inc. for Your Urethane Casting Needs?

For over 45 years, Uniflex, Inc. has been the trusted partner for companies requiring custom molded urethane and rubber solutions. Here’s what sets us apart:

Complete In-House Capabilities: Design, mold-making, casting, machining, and assembly all under one roof for superior quality control and faster turnaround

Expert Engineering Support: Our experienced team optimizes your designs for performance and cost-effectiveness

Multi-Industry Experience: Proven expertise serving oil & gas, automotive, mining, robotics, aerospace, marine, and agricultural sectors

Material Versatility: Access to comprehensive urethane formulations, including specialty grades for demanding applications

Competitive Pricing: Efficient processes and strategic sourcing deliver exceptional value without compromising quality

Fast Lead Times: In-house capabilities eliminate external dependencies, reducing time-to-market

Quality Commitment: Rigorous quality control ensures every part meets or exceeds specifications

Contact Uniflex, Inc. Today

Let us help you select the right urethane solution for your application. Whether you need a single prototype or thousands of production parts, Uniflex, Inc. delivers the quality, expertise, and service you deserve.

Don’t settle for off-the-shelf components when custom urethane casting can deliver exactly what your application demands. Contact Uniflex, Inc. today and discover how our 45+ years of experience can solve your toughest manufacturing challenges.

Frequently Asked Questions

How does urethane compare to rubber in terms of performance?

Urethane significantly outperforms rubber in several key areas: it offers 3-10x better abrasion resistance, superior load-bearing capacity, better resistance to oils and hydrocarbons, and maintains properties across a wider temperature range. However, rubber excels in extreme cold flexibility (below -40°F) and certain acid environments. Urethane also provides better tear strength and can achieve higher hardness levels than rubber.

What is the typical lifespan of urethane parts in industrial applications?

Lifespan varies dramatically based on application conditions. In moderate-duty applications, urethane parts typically last 3-7 years. Heavy-duty mining or material handling applications may see 2-5 years depending on abrasion exposure. Properly formulated urethane components can outlast rubber equivalents by 300-500% and metal parts by 500-1000% in high-abrasion environments. Regular inspection and proper maintenance significantly extend service life.

Can urethane parts be repaired if damaged?

In many cases, yes. Minor surface damage can be repaired using urethane adhesives or patch compounds matched to the original durometer. Deep cuts, tears, or structural damage may be repairable depending on part function and load requirements. However, repairs rarely restore 100% of original strength. For critical applications, replacement is recommended over repair. Some manufacturers offer repair services or can advise on field repair protocols.