There are few industries that depend more on machinery and equipment than mining. If you work in the mining industry, you know that your equipment is going to be pushed to the limits, as far as Mother Nature and the law will allow. So, it goes without saying that the mining tools and equipment used must be resilient and durable above all else.

In the dusty, dirty, hazardous, and harsh environments of mining, the equipment designers and manufacturers are increasingly paying more attention to the “little things”; like machine components that help the big machines perform better and for longer.

This is where cast urethane mining parts come in. (And the key is to find a dependable manufacturer to work with.)

Urethane Mining Industry: Why the Modern Mining Industry Prefers Urethane

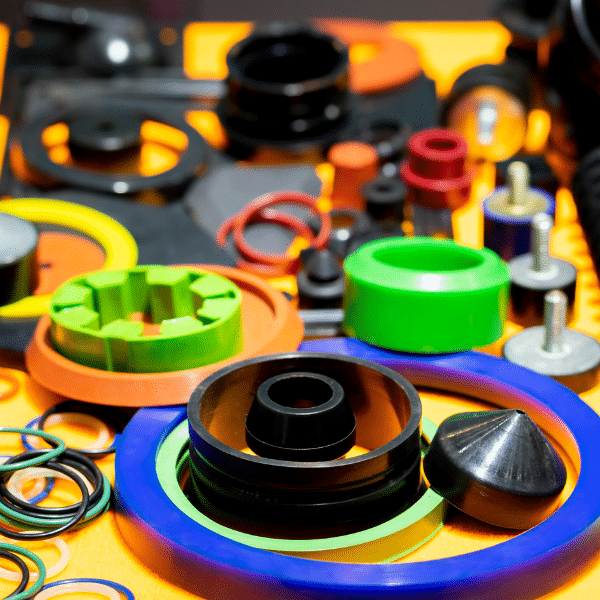

Urethane or to be more specific, cast polyurethane parts have always been known for their incredible properties, such as:

- Abrasion resistance

- Unmatched resilience

- High load-bearing capacity

- Impact strength.

Now, as mining designers and manufacturers are looking for ways to increase the longevity and performance of mining equipment, urethane has naturally become a preferred choice.

One of the biggest advantages of using urethane mining parts is that it’s super flexible; not just in physical performance (like rubber), but also because it comes in a liquid form. Liquid urethane allows the combination of different formulations, in addition to metering, and dispensing it with unparalleled precision.

This unique process allows the making of urethane mining parts into any form, density, or weight. This is while still ensuring the component stays completely uniform and consistent throughout the entire run. In addition, when compared to plastics and other elastomers, urethane offers far more versatility, durability, toughness, and strength in reduced costs.

Imagine the flexibility and resiliency of rubber combined with the performance benefits of metals and engineered plastics – that’s urethane. Tweaking of this material due to its sheer adjustable nature of the chemical properties is easy in order to provide several new opportunities to address performance problems that other materials simply can’t solve.

And if that’s not enough, urethane mining parts are much less likely to fail due to deterioration, abrasion, and other forms of damage. Unlike other materials. Cast polyurethane parts will deliver a much superior long-term value to end customers.

Another great benefit of urethane mining parts is their molding and bonding ability to multiple different kinds of substrates such as fiberglass, aluminum, and steel. This allows for added rigidity and strength if necessary.

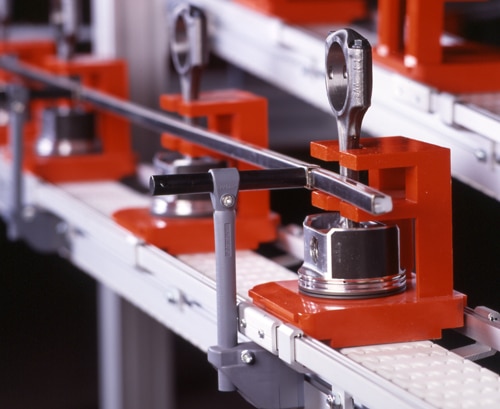

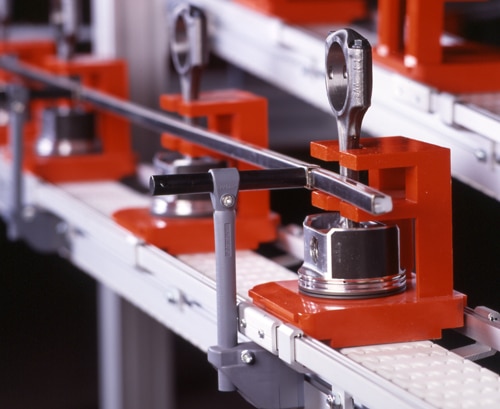

Talk to Uniflex Inc., The Industry Experts, About Urethane Mining

Cast urethane mining parts created at Uniflex Inc. can be custom molded for both low and high-volume production. They are also available in a wide range of hardness’s (durometers). We can cast parts that are as small as a few ounces or as large as hundreds of pounds. If you have any questions or concerns about the urethane mining industry and parts, please call us at 248-486-6000 or contact us online and our representatives will get back to you shortly.