Molded urethane is a plastic material whose creation stems from the chemical reaction between prepolymer resins and specialized curing agents. Products and parts made from molded urethane offer incredible chemical resistance, flexibility, and durability. If you’re wondering what custom molded urethane is, you’ve come to the right place! In this short guide, we will provide you useful insights about this versatile material that a wide spectrum of industries uses, in addition to using it for numerous applications.

What Is Custom Molded Urethane?

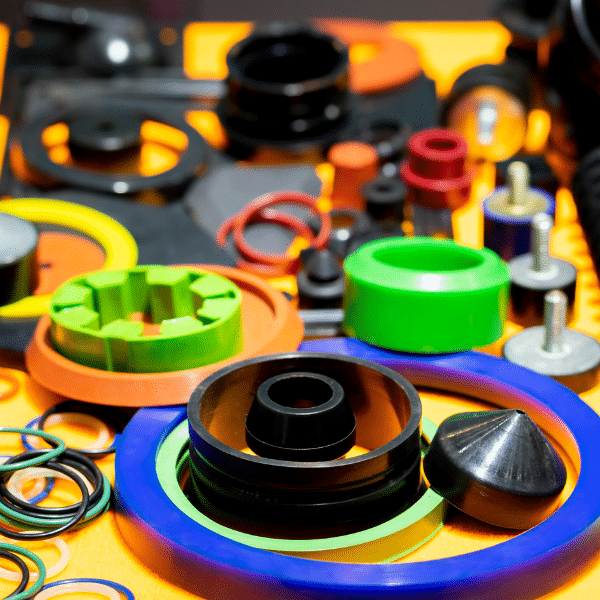

The usage of custom molded urethane products is common when it comes to using them for several industrial purposes. For example, for seals, bushings, rollers, and bumpers. The usage of this tailorable polymer occurs when making small, molded parts like washers all the way up to large multi-hundred-pound components.

Urethane starts as a viscous, liquid prepolymer that we must heat and mix in with a curing agent so the chemical reaction can occur. Urethane is relatively stable and tends to be resistant to most chemicals as well as impingement. Many manufacturers also use additives to improve UV resistance, increase flame retardation, and reduce friction.

When liquid urethane is injected or poured into a mold, the “molded” urethane products take shape. A reaction between prepolymer and curing agent causes the urethane to polymerize and harden. Most times, to ensure lasting quality, these molded products are cured in industrial ovens as well as hot on hot tables. To know more about what custom molded urethane is, you should talk to a dedicated manufacturer with expertise in thermoset plastics, such as Uniflex Inc.

Are Custom Molded Urethane Products Customizable?

If you’re looking for a versatile solution for your manufacturing needs, custom-molded urethane can be a great option. It’s unmatchable in terms of:

- Chemical resistance

- Scraping abrasion resistance

- High impact resiliency

- Vibration dampening

- And much more

But the best part is, we can mold urethane into a plethora of products due to its liquid starting state. This allows the polyurethane material to fill the cavity of pretty much any mold. In other words, urethane has the ability to take shapes that other materials can’t.

We can customize custom molded urethane parts for specific applications by simply adjusting formulations to change the physical properties and hardness (durometer).

Compared to other similar compounds like rubber, urethane has the most versatility. While rubber and other compounds are sometimes vital for certain applications, molded urethane serves as the cheaper and more durable option when it comes to most parts.

In addition to customization, there are numerous other benefits of choosing custom molded urethane to manufacture your parts. For starters, it offers lower-cost tooling. This generally makes urethane costs much lower than rubber molding which requires higher-cost compression molds.

The molding process of urethane is capable of forming parts without any need for costly injection molds. It is extremely precise and can work with a wide range of part sizes. Moreover, urethane molded parts need little to no additional finishing so there is an incredibly fast turnaround time as well.

Talk To Our Dedicated Experts At Uniflex Inc.

At Uniflex Inc., we create custom molded urethane parts for your specific needs.

We can cast a variety of tailored, molded urethane products for multiple purposes with meticulous precision and superior quality. If you have more questions related to what custom molded urethane is, or how it can help you save time and money on your project, call us today at 248-486-6000 or contact us online.