In the world of modern materials, polyurethane stands out as a versatile and innovative substance that has revolutionized various industries. But what exactly is polyurethane, and how does it stack up against traditional plastics? From durability to flexibility, and sustainability to customization, exploring the differences and advantages of polyurethane over conventional plastics reveals a fascinating journey into the future of manufacturing and product development. Join us as we delve into the characteristics that make polyurethane a material of choice in today’s dynamic marketplace.

At Uniflex, Inc., we’re committed to delivering high-performance, custom polyurethane solutions that meet the demands of even the most challenging industrial environments. Whether you need molded urethane products, urethane sheets, rods, bumpers, or precision-matched parts for food processing, manufacturing, construction, or other heavy-duty applications, our advanced formulations and decades of expertise ensure exceptional results.

Explore our full line of cast polyurethane products, engineered to your exact specifications with options including FDA-approved materials and Vulkollan®-equivalent performance. Contact us today at 248-486-6000 to discuss your project needs or shop now and experience the Uniflex difference in quality, durability, and value.

👉Also Read: How Polyurethane Products Are Manufactured – A Detailed Overview

Understanding Polyurethane

Polyurethane, a polymer made of organic units linked by urethane bonds, offers a unique mix of flexibility and rigidity. Formed from the reaction of diisocyanates with polyols, it can be customized for various applications, making it highly adaptable compared to traditional plastics and urethane products.

Polyurethane’s balance of flexibility and rigidity makes it ideal for diverse applications, from soft foams to rigid coatings. Solid foams dominate production, making up 67% of global output in 2016, and are used in products ranging from car seats to insulation materials.

Polyurethanes can be made from a wide variety of raw materials and other materials, leading to diverse chemical properties and applications. This versatility sets urethanes apart from many conventional plastics, offering a broader range of uses and benefits, including cast urethanes.

Manufacturing Process of Polyurethane

Polyurethane production starts with a chemical reaction between isocyanate groups and polyols to form a polymer. Toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI) are commonly used isocyanates. The choice of polyol and isocyanate, along with the degree of cross-linking, determines the final product’s flexibility or rigidity.

Polyurethane manufacturing is highly customizable. Different polyester polyols formulations can be tailored for specific uses, influencing properties like flexibility, heat resistance, and chemical durability. Additives like catalysts speed up reactions, while chain extenders enhance flexibility by lengthening polymer chains.

Safety and functionality are crucial. Flame retardants, though regulated due to health concerns, improve fire safety. Physical blowing agents boost foam expansion while minimizing fire risks. Fillers like processed mineral fibers enhance mechanical properties and lower production costs by reducing the need for liquid chemicals. Water also serves as a blowing agent, creating air pockets within the foam by generating carbon dioxide gas.

This results in a material that can be molded into products ranging from flexible foams to rigid coatings, showcasing cast urethane products’ versatility in manufacturing. When sourcing molded urethane products, it’s essential to work with a reliable supplier who thoroughly understands the unique demands of your application.

👉Also Read: Top Reasons to Choose Cast Polyurethane for Agricultural Use

Traditional Plastics Overview

Traditional plastics include:

- Polyethylene, which is often used for packaging, plastic bags, and containers, because of its flexibility and durability

- Polypropylene, noted for its heat and chemical resistance, which is found in automotive parts, textiles, and consumer products

- Polyvinyl chloride (PVC), commonly used in construction and plumbing, alongside existing plastics.

Each of these plastics has unique properties and uses in daily life.

Manufacturing these plastics usually involves polymerization. Polyethylene is made by converting ethylene gas into solid plastic using heat and pressure. Similarly, polypropylene is produced through polymerization, creating a strong, lightweight material. PVC is manufactured by polymerizing vinyl chloride, using processes like suspension or emulsion polymerization.

Traditional plastics have been industry mainstays for decades, but have limitations regarding environmental impact and performance in certain applications. This is where comparing them with polyurethane becomes particularly interesting.

Comparing Durability and Performance

When it comes to durability and performance, polyurethane consistently outperforms many traditional plastics and elastomers. In numerous industrial applications, polyurethane components can last up to five times longer than rubber counterparts. Unlike rubber, which is prone to cracking, degradation, and fatigue over time, polyurethane maintains its structural integrity, delivering superior wear resistance in environments characterized by friction, abrasion, and mechanical stress.

Polyurethane molds exhibit a wide range of high-performance characteristics, including outstanding impact resistance, flexibility, and long-term durability. Polyurethane elastomers, in particular, offer exceptional resilience and load-bearing capabilities due to their segmented molecular structure, comprised of both soft and hard segments, which allows for a diverse range of mechanical properties. These properties can be further enhanced through precision manufacturing techniques such as injection molding.

Additionally, the hardness of polyurethane materials can be finely tuned through custom formulations, accommodating applications that require anything from soft, cushioning components to rigid, load-supporting structures. Thermoset polyurethane, for example, offers excellent resistance to abrasion, UV exposure, and ozone, making it a reliable solution for both indoor and outdoor use across demanding operational environments.

Environmental Impact

As environmental concerns continue to influence material selection and manufacturing practices, the impact of polyurethane has come under increasing scrutiny. Conventional polyurethane, derived from petroleum-based sources, is resistant to natural degradation and can contribute to long-term environmental pollution when improperly disposed of.

However, recent advancements in recycling technologies are helping to mitigate this impact. Innovative chemical recycling methods now allow polyurethane waste to be broken down into its original monomers, which can then be reused to create new materials. This closed-loop approach marks a meaningful step toward reducing the material’s environmental footprint.

In parallel, the development of bio-based polyurethanes—produced from renewable resources such as vegetable oils or other plant-based feedstocks—offers additional promise. These alternatives can significantly lower greenhouse gas emissions and reduce reliance on finite fossil fuels. By incorporating bio-based inputs, manufacturers are helping to foster a more sustainable, circular economy without sacrificing the mechanical performance that polyurethane is known for.

While challenges remain—particularly in scaling sustainable production and improving end-of-life management—these innovations underscore the industry’s commitment to balancing high-performance material solutions with environmental responsibility.

Versatility in Applications

Polyurethane’s exceptional versatility is one of the key factors behind its widespread adoption across numerous industries. Classified by its chemical composition, polyurethane is manufactured in various forms—including flexible and rigid foams, coatings, adhesives, sealants, and elastomers—each tailored to specific functional requirements.

In the household appliance sector, polyurethane plays a vital role in thermal insulation, particularly in refrigerators and freezers, where energy efficiency and long-term performance are critical. The medical field also benefits from polyurethane’s biocompatibility and comfort, using it in hospital bedding, surgical drapes, wound dressings, and catheter components.

In electronics, polyurethane functions as an effective potting and encapsulating compound, protecting sensitive components from moisture, vibration, and thermal fluctuations. Its use in composite wood products—as a binder for engineered panels and boards—enhances structural integrity while reducing the need for formaldehyde-based adhesives.

The automotive industry relies heavily on polyurethane for its combination of durability and lightweight properties. It is commonly found in seat cushioning, bumpers, suspension bushings, and interior trim components, contributing to both comfort and fuel efficiency.

In the construction sector, polyurethane insulation materials provide superior thermal resistance, improving energy conservation in residential and commercial buildings. Additionally, its use in protective packaging foam ensures the safe transport of fragile goods across various industries.

Ultimately, polyurethane’s adaptability to meet specific mechanical, thermal, and aesthetic demands underscores its value as a multifunctional material essential to modern manufacturing and product design.

Choosing the Right Material

Choosing the right material involves considering several factors, and polyurethane often stands out as the correct material. It can be formulated for various tensile and compressive strengths, supporting different loads without deformation. Its elasticity and resilience enable it to absorb shocks and return to its original shape, making it ideal for applications requiring durability under repeated stress.

Polyurethane is also effective at shock absorption, making it valuable for protecting equipment. In demanding applications, polyurethane bushings can handle higher loads than rubber while maintaining structural integrity.

For product designers, engineers, and materials science enthusiasts, understanding these properties is crucial for making informed decisions in product design. Whether for automotive parts, industrial machinery, or consumer goods, polyurethane provides a versatile and robust solution.

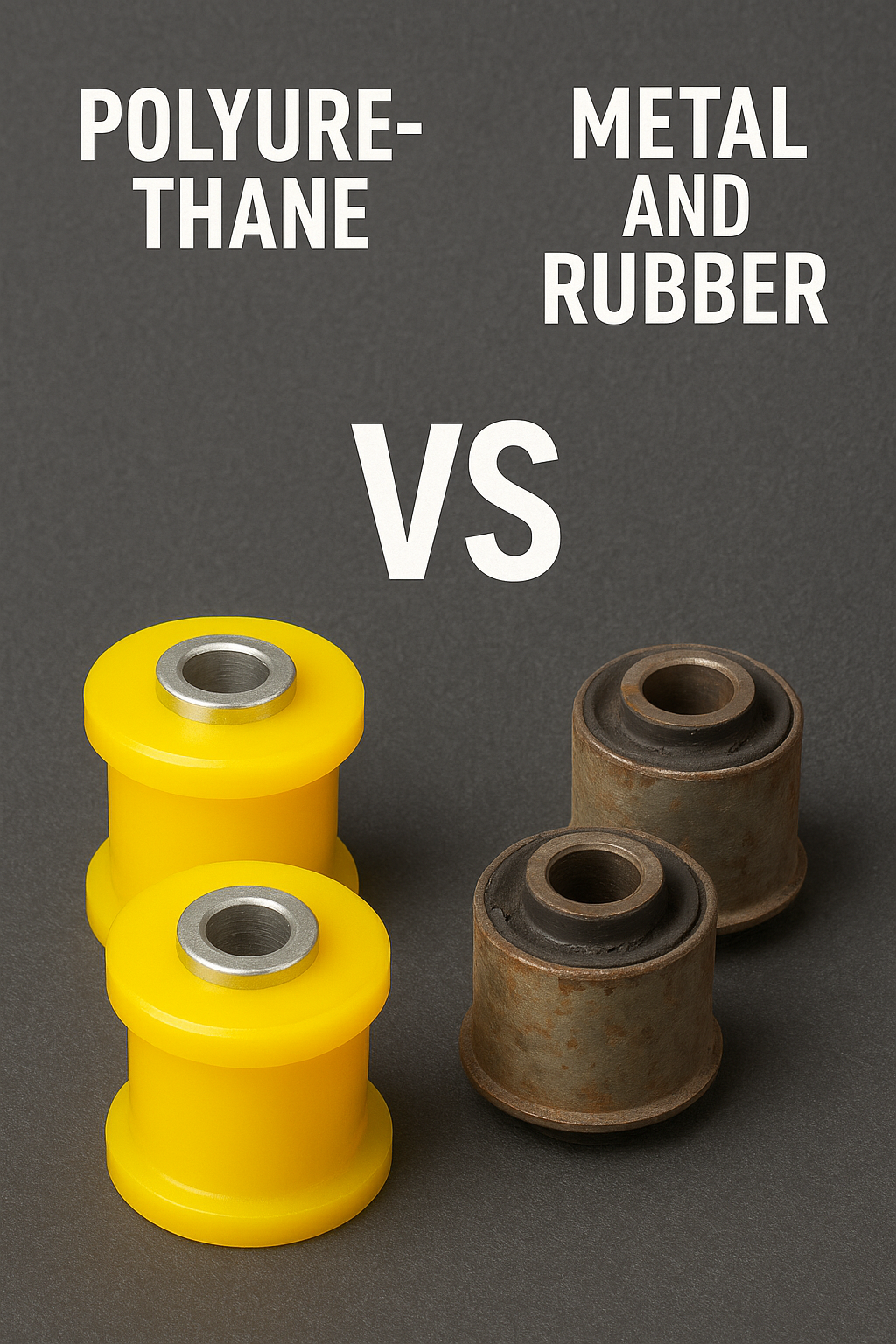

Polyurethane vs. Metal and Rubber

Polyurethane offers a compelling set of advantages over traditional materials like metal and rubber, particularly in demanding industrial and mechanical applications.

Compared to metal components, such as bushings, polyurethane provides superior flexibility, allowing it to absorb shocks, vibrations, and movement far more effectively. This shock-absorbing capability not only reduces wear on adjoining parts but also significantly minimizes operational noise, a benefit that metal cannot match due to its rigidity and lack of inherent damping properties. Furthermore, polyurethane exhibits excellent impact resistance, making it well-suited for dynamic applications where repeated stress and movement are common.

When measured against rubber, polyurethane demonstrates enhanced load-bearing capacity, resilience, and wear resistance. Unlike rubber, which tends to degrade over time due to environmental exposure and material fatigue, polyurethane maintains structural integrity under prolonged stress. Its superior resistance to oils, solvents, greases, and a wide range of chemicals makes it particularly valuable in harsh operating environments where rubber components would typically fail or degrade more quickly.

Additionally, polyurethane’s customizable hardness and flexibility—achieved through precise formulation—allow for tailored performance characteristics across a broad spectrum of applications. This versatility makes it the preferred material for components requiring durability, dimensional stability, and chemical resistance.

Is Polyurethane a Plastic?

Polyurethanes are classified as true elastomers, setting them apart from traditional plastics by their manufacturing methods and performance traits. Thermoset polyurethanes excel in durability and impact resistance compared to conventional plastics, making them ideal for high-stress applications. Unlike typical plastics that can deform permanently, thermoset polyurethanes return to their original shape after being stretched or compressed.

This customizability allows polyurethanes to be tailored for specific performance needs, unlike standard off-the-shelf plastics. In industries requiring high abrasion resistance, polyurethanes are preferred due to their toughness and resistance to cracking.

👉Also Read: Choosing Between Custom Polyurethane or Rubber Wheels: Making the Right Choice

Partner with Uniflex, Inc. for Custom Polyurethane Solutions That Deliver Performance and Sustainability

In summary, polyurethane stands out as a highly versatile and durable material that can outperform traditional plastics in many applications. Its ability to be customized for specific needs, combined with its environmental advancements, makes it a compelling choice for various industries. The comparison with traditional plastics, metal, and rubber highlights polyurethane’s superior qualities in terms of flexibility, impact resistance, and overall performance.

As we continue to seek sustainable and high-performance materials, polyurethane offers a promising solution that balances functionality with environmental responsibility. Whether you’re a product designer, engineer, or consumer, understanding the benefits and applications of polyurethane can help you make informed decisions for your projects and products.

At Uniflex, Inc., we are dedicated to delivering high-quality polyurethane solutions tailored to meet the evolving demands of modern industries. With decades of experience in custom molding and material innovation, we help our clients harness the full potential of polyurethane—whether for durability, flexibility, chemical resistance, or sustainability. If you’re exploring advanced material options for your next project, our team is ready to collaborate and provide expert guidance from concept to completion. Contact Uniflex, Inc. today to discover how our polyurethane products can elevate the performance and longevity of your applications.