Polyether Urethane vs. Polyester Urethane

When it comes to polyurethane, there are two main types: polyether urethane and polyester urethane. Although they are both polyurethanes, each has its own unique set of physical properties that are designed for specific applications. Below is a comparison of polyether and polyester polyurethanes showing lists of properties as well as applications for each material.

Polyester Urethane

In fact, polyesters are typically famous for their superior sliding abrasion resistance. This makes them excellent for applications where abrasion subjects the polyurethane surface to high levels of friction, such as with chute liners and scraper blades. Typically, this is the main defining attribute when comparing polyesters with other materials. Polyesters are often called the “workhorse” of high abrasion applications and have gained an excellent reputation when used in highly abrasive environments.

Properties:

- Excellent Abrasion Resistance

- Better Shock Absorption

- Higher Tensile Strength

- Good Chemical Resistance

- Withstand Higher Temperatures Longer

Applications:

- Scraper blades

- Chute liners

- Hopper liners

- Wear pads

- Snowplow blades

- Screening grids

Polyether Urethane

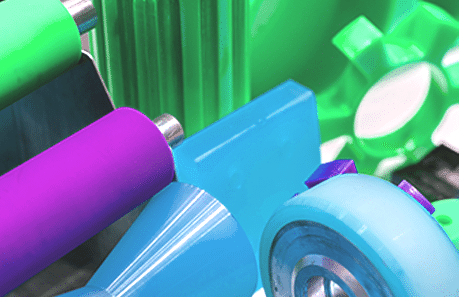

In fact, polyethers are the most common polyurethanes used in the cast elastomer industry. They generally have better dynamic properties than polyesters and are used in wide range of applications such as rollers, bumpers, and bushings. Polyethers tend to make up the majority of polyurethane parts because they are easy to work with and offer more desirable physical properties. Another very interesting thing about polyethers is that they can be tailored with specific additives to perform on the same level or better as polyesters for abrasion resistance. This results in a material that is essentially a hybrid polyether and performs just like a polyester in high scraping abrasion applications.

Properties:

- Excellent Dynamic Properties

- Hydrolytic Stability

- Low-Temperature Flexibility

- Good High-Temperature Resistance

- UV Resistance

- Better Rebound

Applications:

- Rollers

- High load casters

- Skateboard wheels

- Body Blocks

- Bumpers

- Bushings

- Coil storage pads

- Gears and sprockets

- Pulleys

- Couplings

So, if you have any questions about polyurethane elastomers, do not hesitate to give us a call at (248) 486-6000 or send us a message. We have an experienced staff that is always willing to lend support.