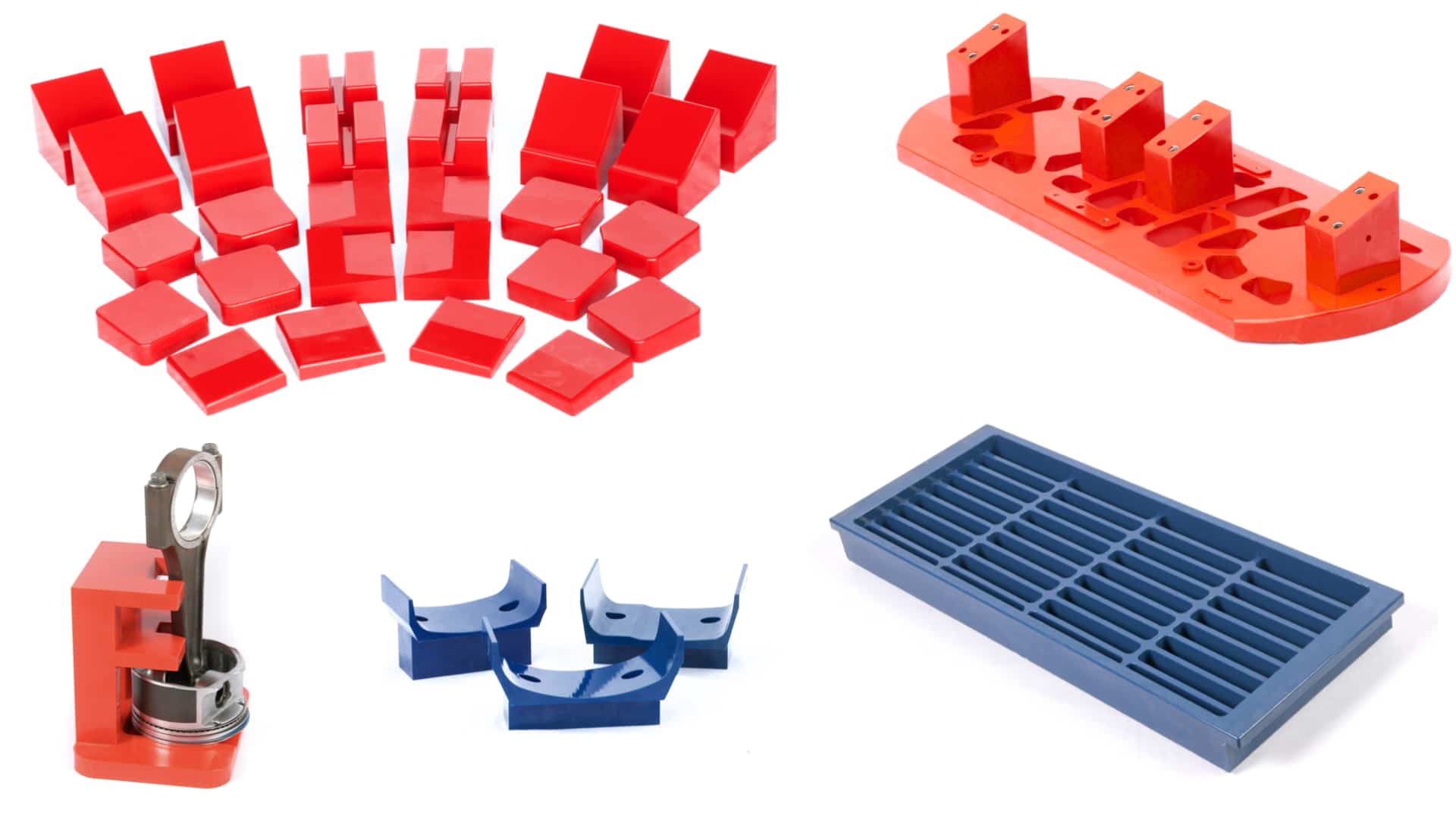

Urethane Dunnage

Dunnage made from urethane is an excellent custom solution for high impact and high wear industrial applications. Dunnage nests, racks, pallets, body block, and buckets have become an industry standard for safely transporting finished and unfinished goods through assembly and shipping operations. Urethane dunnage is a commonly used commodity in the automotive industry as well as in many other industries because of its non-marring nature and high load bearing capabilities.

Custom Dunnage Solutions

Custom part dunnage is a very common specialty used in the manufacturing, packaging, and shipping industries. Custom molded dunnage can be made in almost any shape and can be manufactured to perfectly match the contours of whatever the dunnage part is carrying. All of our urethane dunnage is completely customizable and can be shaped in any way specified by the customer. Furthermore, it can be produced in any hardness from 40 Shore A to 95 Shore A as well as 60 to 70 Shore D.

Benefits of Polyurethane Dunnage

Non-Marring

One of the most noticeable benefits of urethane dunnage is that it is non-marring. This allows finished good to be carried in the dunnage without getting scuffed, scratched, or dented. Most solid plastic dunnage, such as HDPE dunnage, can cause irreversible damage to finished goods. The same can happen with rubber dunnage. Although rubber dunnage is soft and won’t scratch finished good, it will still leave a rubber residue on the surface.

Completely Customizable

Urethane is unique in that it can be molded into seemingly any shape with low-cost tooling and fast lead times. All poly dunnage can be manufactured using a host of standard colors as well as a host of different durometers. This allows color coded organization and hardness tailored to match specific operations.

Low Cost When Compared to Machined Dunnage

When compared to machined dunnage, urethane is a fraction of the price. Most 3D machining operations take up large amounts of time which equates to unnecessary costs. However, when working with polyurethane, one CNC machined master pattern is made. That master pattern is then used to make numerous molds that can be used to rapidly produce parts. This equates to lower costs and faster production.

Have Any Questions About Urethane Dunnage or Custom Molding?

Please feel free to contact us. We have a team of experienced engineers and customer service representatives ready to assist you in whatever project you may be working on.

What is Unique About Urethane Dunnage?

Dunnage made from polyurethane is one of the most cost-effective and versatile dunnage solutions. Because of their liquid starting state, urethane resins can be molded into an infinite number of shapes with high precision. Dunnage parts can be molded to fit the exact contours of the product being shipped or carried down the production line. Urethane is also extremely rugged and can be used repeatedly without being damaged significantly. Just send us a your drawing file or provide us your dimensions and we can easily design a production protocol for producing your custom urethane dunnage.

Reasons to Use Polyurethane for Dunnage

Polyurethane is:

- Resilient

- Durable

- Cost Effective

- Impingement Resistant

- Abrasion Resistant

- Chemical & Solvent Resistant

- Oil Resistant

- Non-conductive

- Non-absorptive

- Sound dampening

- Impact Absorbing

- Customizable

More Products

Incredibly useful due to its ability to be molded into a seemingly infinite number of shapes, sizes, and hardness ranges.

We offer high quality, custom rubber compression and transfer molding to produce high quality, economical rubber products that adhere to your specific requirements.

Incredibly useful due to its ability to be molded into a seemingly infinite number of shapes, sizes, and hardness ranges.

We are able to hold the most stringent tolerances that always meet or exceed customer expectations while ensuring an economical price.

We supply more styles and sizes of Kadant Unaflex brand Expansion Joints than any other distributor in the world and offer some of the most competitive pricing available.

Our product line includes molded & pultruded grating, handrail, ladders, structural shapes, stair treads, grating accessories, and FRP doors.

Custom manufactured from our famous non-conductive, ultra-durable UNIDURE© material, our electrical safety devices can be tailored for use in any lockout or tagging situation.

Our press fit cam follower sleeves are designed for ease of use and cost effective/efficient emplacement, while also maintaining exceptionally high quality.

The Uniflex Pipe Coupling has successfully solved frequent leakage, intensive maintenance, and stocking difficulties associated with ground join-pipe unions.